Multi-stage plasma carbon material cracking reactor, and method for producing acetylene by using carbon material

A technology of plasma and carbonaceous materials, applied in the field of ions, can solve the problems of single-stage reactor height that cannot be lengthened at will, limited conversion, energy waste, temperature distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

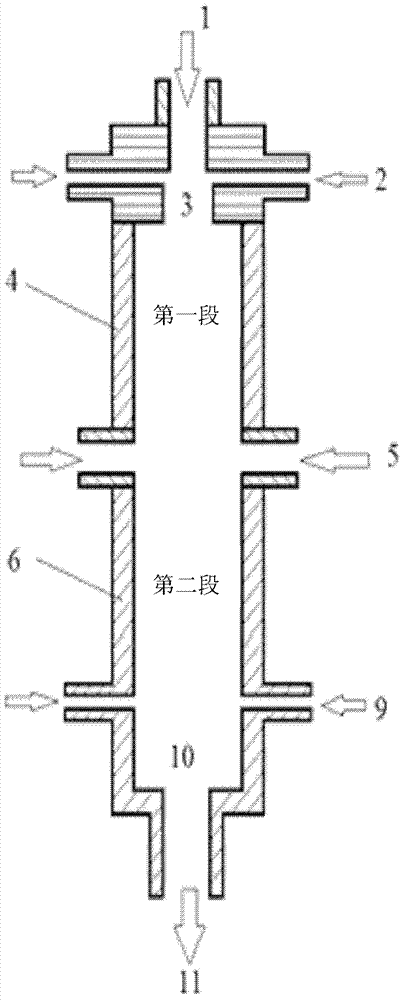

[0103] Its schematic is shown in figure 1 The two-stage plasma-pyrolysis coal reactor is used to convert coal into acetylene and other chemicals. The two-stage plasma reactor operates by means of a plasma generator with an input power of 10 kW to 20 MW. like figure 1 As shown, the reactor consists of two straight passages (ie, reaction tubes) 4 and 6, a top inlet for a first heating gas 1, two inlets for pulverized coal and a carrier gas feed 2, and two first inlets for heating gas 1. Two inlets for heating gas 5, two inlets for quenching medium 9 and one outlet 10 for cracking product 11 are composed of pulverized coal and carrier gas feed 2 and first heating gas 1 in the mixing zone 3 of pulverized coal and carrier gas Below the inlet of feed 2 and immediately above the first section 4 of the reaction tube. The walls of the reactor were constructed of copper near the three heating gas inlets and steel in other areas, while the reactor was cooled by water circulating at hi...

Embodiment 2

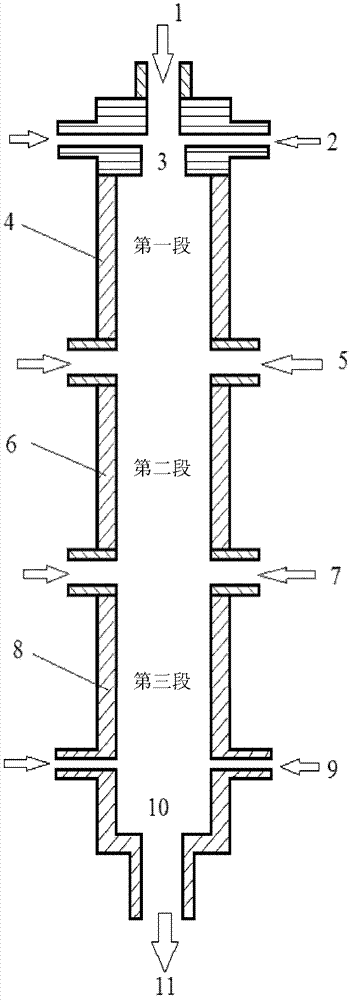

[0119] The experimental procedure described in Example 1 was repeated, except that the two-stage plasma reactor was replaced by a three-stage plasma reactor, wherein the three-stage plasma reactor was assisted by a plasma generator with an input power of 10 kW to 20 MW. come to work. like figure 2 As shown, the reactor consists of three straight channels (ie reaction tubes) 4, 6, and 8, a top inlet for a first heating gas 1, two inlets for pulverized coal and a carrier gas feed 2, Two inlets for the second heating gas 5, two inlets for the third heating gas 7, two inlets for the quenching medium 9, and one outlet 10 for the cracked product 11 are composed of pulverized coal and carrier gas feed 2 and the first The mixing zone 3 of the heating gas 1 is placed under the inlet of the pulverized coal and the carrier gas feed 2, and abuts the upper part of the first section 4 of the reaction tube. The walls of the reactor were constructed of copper near the 5 heating gas inlets ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com