Foamed geopolymer and preparation method and application thereof

A geopolymer and foam technology, used in applications, other household appliances, household appliances, etc., can solve the problems of unsatisfactory crack resistance and waterproof performance, short service life, etc., and achieve excellent durability, excellent waterproof performance, and crack resistance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

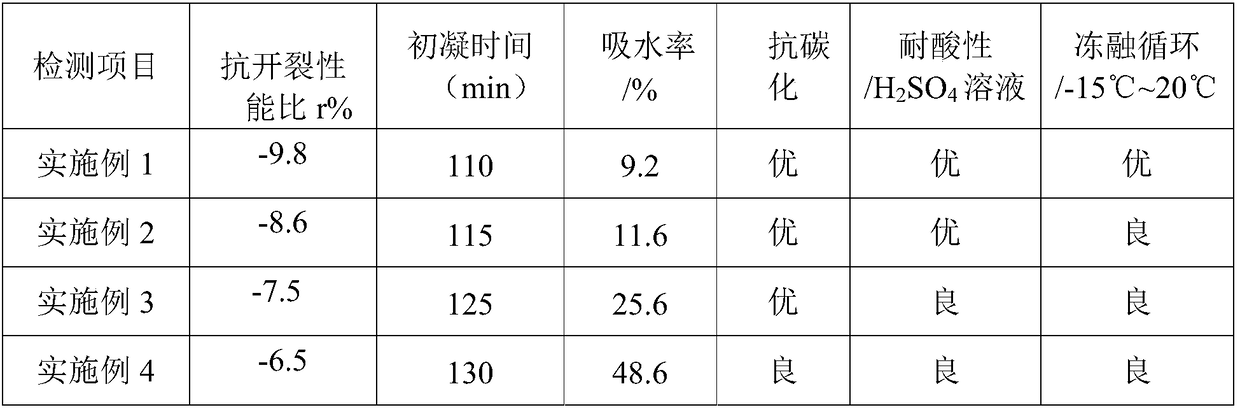

Examples

Embodiment 1

[0043] This embodiment provides a foam geopolymer for tunnel composite lining. The preparation method includes: pour 2 parts by weight of paraffin wax emulsion and 0.5 parts by weight of absolute ethanol into a mixer, stir at a slow speed for 1 min; then pour 39 parts by weight of metakaolin, 2 parts by weight of fly ash, 0.5 parts by weight of modified sisal fiber and 45 parts by weight of sodium water glass, stirred at a slow speed for 6 minutes; then added 7 parts by weight of water, stirred at a slow speed for 3 minutes ; Then add 0.5 parts by weight of foam stabilizer and 3.5 parts by weight of hydrogen peroxide with a concentration of 30%, and stir at a slow speed for 2 minutes. Then stir rapidly for 3 minutes, pour, vibrate, and cure for 28 days under standard curing conditions to obtain the foam geopolymer.

Embodiment 2

[0045] This embodiment provides a foam geopolymer for tunnel composite lining. The preparation method includes: pouring 1.5 parts by weight of paraffin wax emulsion and 0.4 parts by weight of absolute ethanol into a mixer, stirring at a slow speed for 1 min; then pouring 36 parts by weight of metakaolin, 1.5 parts by weight of fly ash, 0.6 parts by weight of modified sisal fiber and 47 parts by weight of sodium water glass, stirred at a slow speed for 6 minutes; then added 7 parts by weight of water, stirred at a slow speed for 3 minutes ; Then add 0.4 parts by weight of foam stabilizer and 4 parts by weight of 30% hydrogen peroxide, and stir at a slow speed for 2 minutes. Then stir rapidly for 3 minutes, pour, vibrate, and cure for 28 days under standard curing conditions to obtain the foam geopolymer.

Embodiment 3

[0047] This embodiment provides a foamed geopolymer for tunnel composite lining. The preparation method includes: pouring 1 part by weight of paraffin wax emulsion and 0.3 parts by weight of absolute ethanol into a mixer, stirring at a slow speed for 1 min; then pouring 30 parts by weight of metakaolin, 1 part by weight of fly ash, 0.8 parts by weight of modified sisal fiber and 50 parts by weight of sodium water glass, stirred at a slow speed for 6 minutes; then added 10 parts by weight of water, stirred at a slow speed for 3 minutes ; Then add 0.3 parts by weight of foam stabilizer and 5 parts by weight of 30% hydrogen peroxide, and stir at a slow speed for 2 minutes. Then stir rapidly for 3 minutes, pour, vibrate, and cure for 28 days under standard curing conditions to obtain the foam geopolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com