U-shaped two-stage differential eddy current probe, detection system and detection method

A differential eddy current and detection system technology, applied in the direction of measuring devices, analyzing materials, and material analysis by electromagnetic means, can solve differential signal errors, induction coils cannot share the same magnetic circuit, and induction coils cannot be lifted from the same height Or complete symmetry and other issues, to achieve accurate detection, suppression of lift-off effects, and easy engineering implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

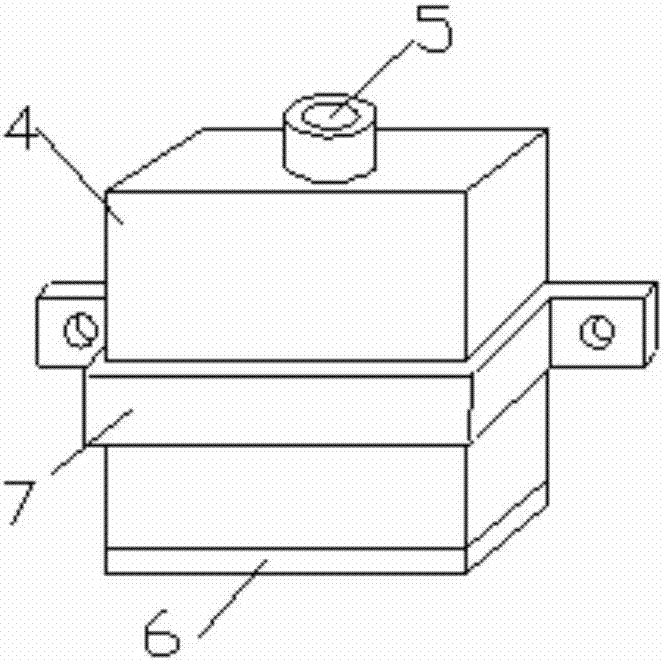

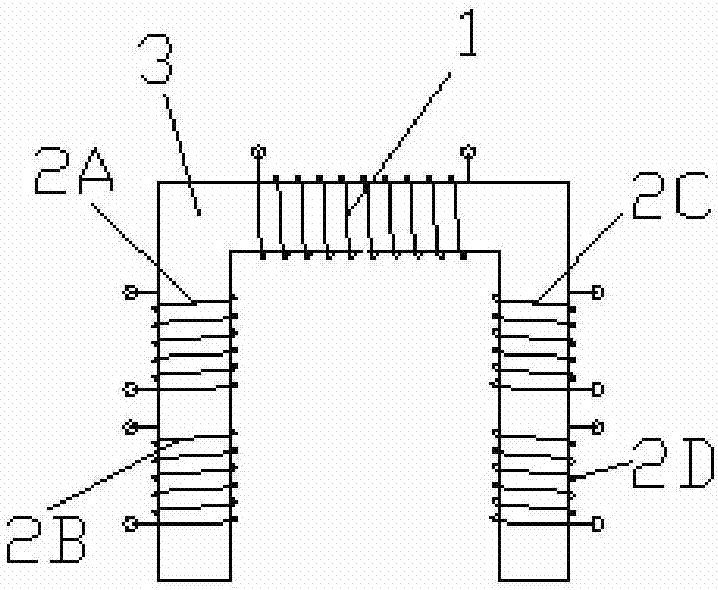

[0037] Embodiment 1: as figure 1As shown, the U-shaped two-stage differential eddy current probe includes excitation coil 1, induction coil 2A, 2B, 2C, 2D, U-shaped iron core 3, probe shell 4, terminal head 5, bottom cover 6, and fixing bracket 7; The U-shaped iron core 3 is made of silicon steel, the excitation coil 1 is wound on the top of the U-shaped iron core 3, and the four induction coils 2A, 2B, 2C, and 2D are wound on both sides of the U-shaped iron core 3, with 2 coils on each side. The four induction coils are identical and distributed axially symmetrically; the probe shell 4 is made of industrial pure iron, the top of the probe shell 4 has a hole, and the terminal 5 is fixed, and the wiring of the five coils is made by the terminal 5 The bottom cover 6 is made of ceramic fiber material, and the bottom cover 6 axially compresses and encapsulates the U-shaped iron core 3 with coils in the probe shell 4; the fixed bracket 7 is installed on the probe shell 4 On the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com