Microbial composite additive used for cement-based material cracking self-repairing and applications thereof

A technology for compounding admixtures and cement-based materials, applied in the field of self-healing additives for cement-based materials, can solve the problems of limited repair amount, complicated process, low repair efficiency, etc., and achieves good durability and volume stability, and is environmentally friendly. , the effect of saving maintenance funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

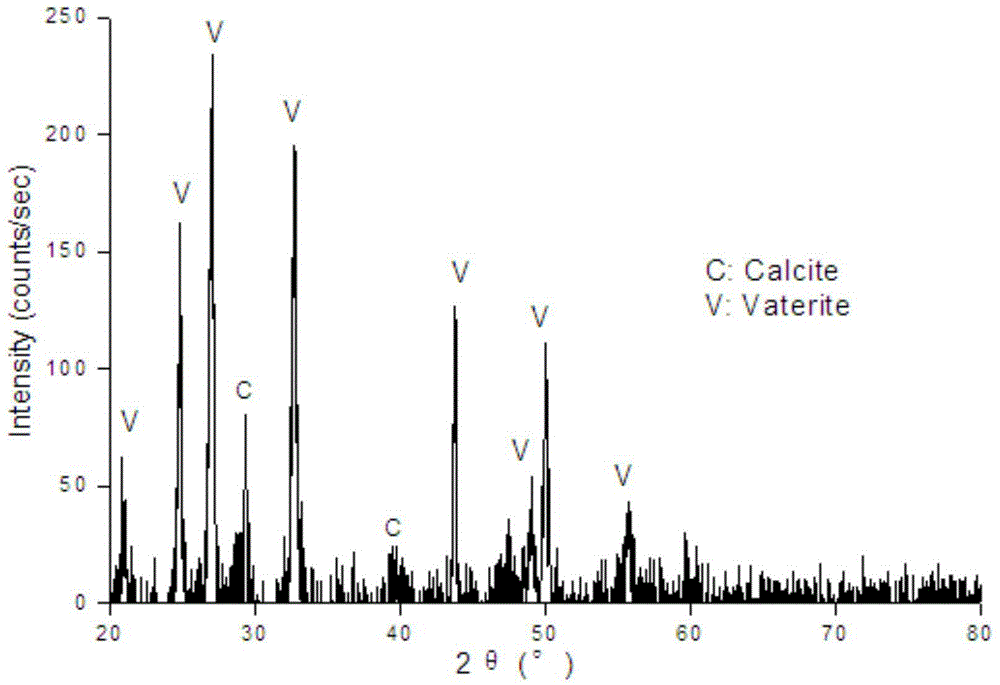

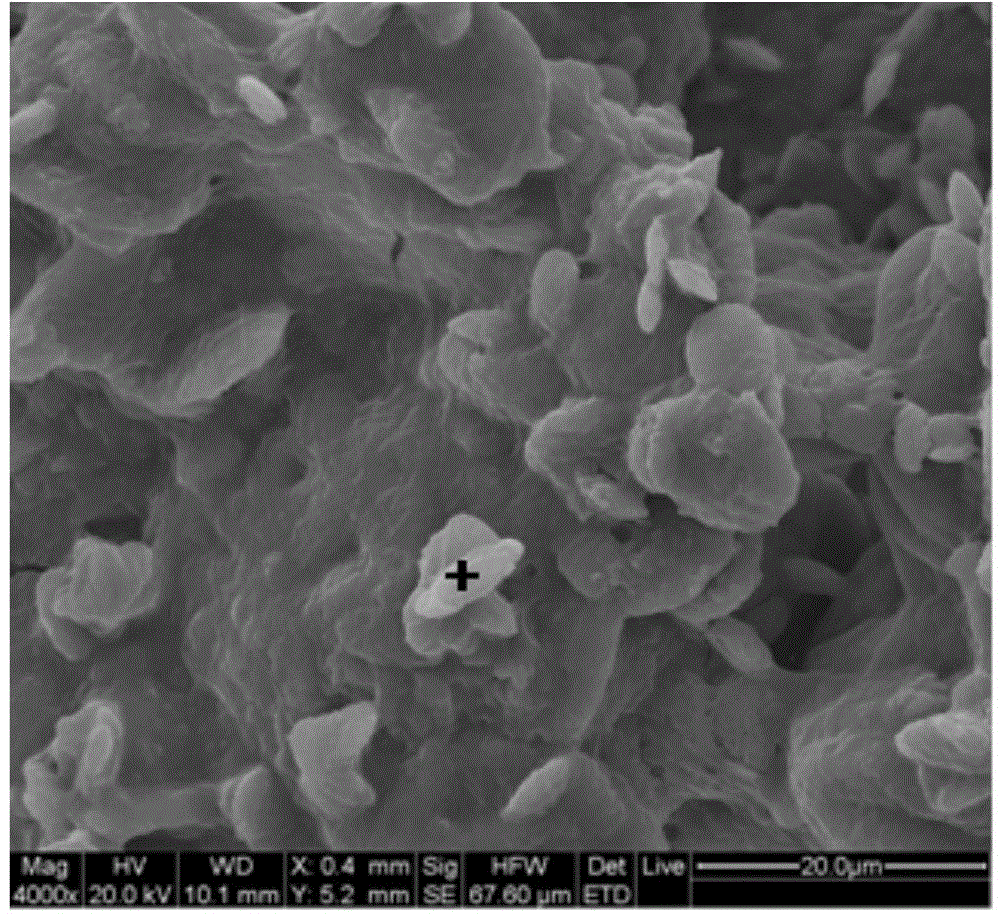

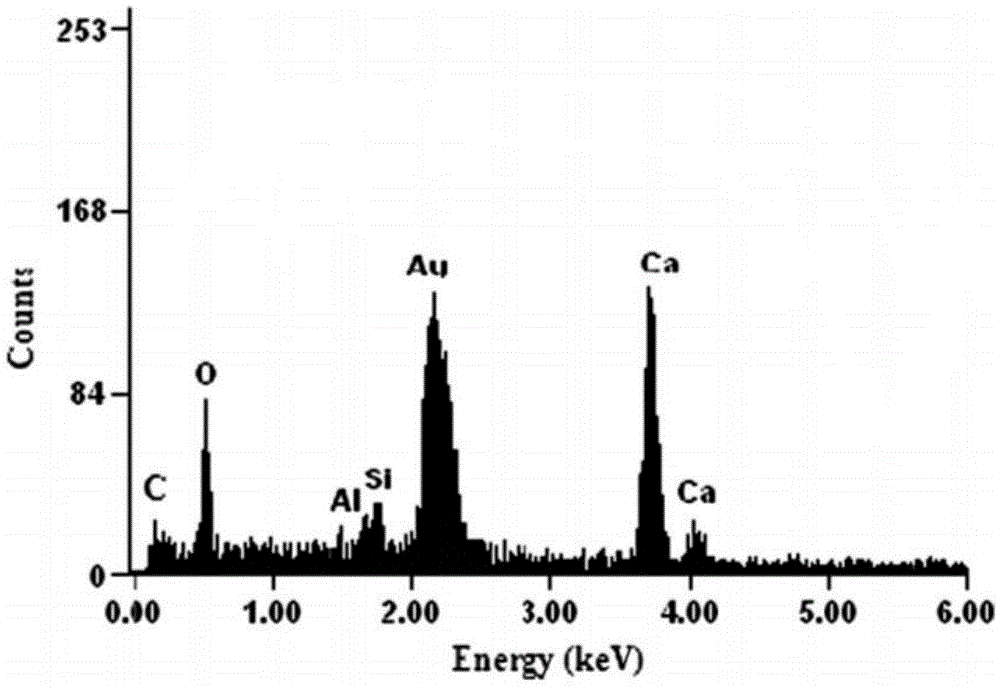

[0021] Examples 1-3: Preparation of microbial composite admixture for self-healing cracking of cement-based materials

Embodiment 1

[0023] A kind of preparation method of microbial composite admixture, bacterial strain Bacillus cohnii is inoculated in the basal culture medium in a conventional manner, and the composition of this basal culture medium is counted as: peptone 5g, beef extract 3g, sodium bicarbonate 0.42g, carbonic acid Sodium 0.53g, water 1000ml, and adjust the pH value to 9.7 with 1mol / L NaOH solution. Then, shake culture at 37° C. on a water bath shaker at a speed of 120 rpm for 48 hours. After centrifuging the acquired culture solution at a speed of 4000rpm for 15min in a centrifuge, the supernatant was removed and the wet cells of the strain were collected with deionized water, and the final concentration of the bacteria solution was controlled at 3.3×10 7 cell / ml range. Add repair nutritional components and auxiliary components to every 100ml of bacterial liquid. The composition of the restoration nutrition component is: 1.8g of calcium glutamate, 0.1g of yeast extract; the composition ...

Embodiment 2

[0025] A kind of preparation method of microbial compound admixture, bacterial strain Bacillus cohnii is routinely inoculated in subbasal medium, the composition of this basal medium is counted as: peptone 4g, beef extract 2.4g, sodium bicarbonate 0.4g, Sodium carbonate 0.5g, water 1000ml, and use 1mol / L NaOH solution to adjust the pH value to 9.2. Then, shake culture at 25° C. on a water bath shaker at a speed of 100 rpm for 36 hours. After centrifuging the obtained culture solution at a speed of 3000rpm for 20min in a centrifuge, the supernatant was removed and the wet cells of the strain were collected with deionized water, and the final concentration of the bacteria solution was controlled at 2×10 7 cell / ml range. Add repair nutritional components and auxiliary components to every 100ml of bacterial liquid. The ingredients of the restorative nutritional component are: 0.9g of calcium glutamate, 0.1g of yeast extract; the ingredients of the auxiliary component are: 18g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com