Application of Hydrophobic Microcapsules in Improving Concrete's Permeability

A technology of impermeability and microcapsules, which is applied in the field of road materials, can solve the problems of reduced mechanical properties, increased concrete cost, and poor compactness, and achieves the effects of simple preparation process, improved impermeability, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment provides a kind of impermeable concrete, is made up of following raw material by mass percentage: hydrophobic microcapsule is 0.3%, cement is 17.7%, aggregate is 74.7% (wherein fine aggregate is 21.4%, coarse aggregate is 53.3%), water is 7.3%.

[0027] Among them, coarse aggregate: limestone gravel, the crushing value is 15.1%, and the particle size is 5mm to 31.5mm;

[0028] Fine aggregate: natural river sand with a fineness modulus of 2.51 and a particle size of less than 5mm;

[0029] Cement: P·C32.5 cement, the stability is qualified, and the strength grade meets the requirements of GB175-2007 "General Portland Cement Standard".

[0030] Based on the raw material formula of this embodiment, the specific preparation process of the anti-permeability concrete of this embodiment is as follows:

[0031] Step 1, weigh 2g of gelatin and dissolve it in 200ml of deionized water, heat and stir until it is completely dissolved, and obtain an aqueous p...

Embodiment 2

[0044] The present embodiment provides a kind of impervious concrete, is made up of following raw material by mass percentage: hydrophobic microcapsule is 0.1%, cement is 17.7%, aggregate is 74.9% (wherein fine aggregate is 21.6%, coarse aggregate is 53.3%), water is 7.3%.

[0045]The requirements for raw materials and the preparation method of the impermeable concrete in this example are the same as those in Example 1. The difference is that the hydrophobic material uses sodium methyl silicate.

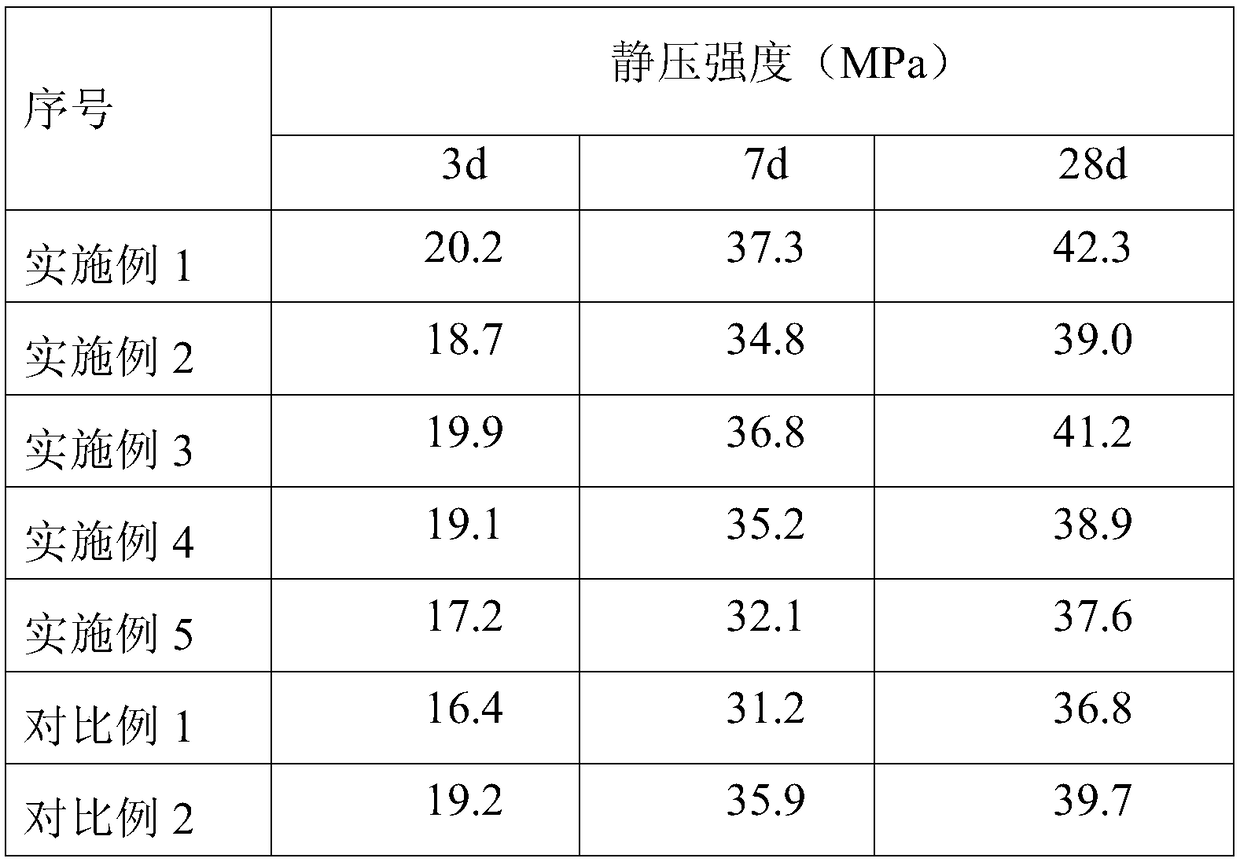

[0046] The test method of the cement concrete specimen of this embodiment is the same as that of Example 1, and the test results are shown in Table 1-3.

Embodiment 3

[0048] The present embodiment provides a kind of impervious concrete, is made up of following raw material by mass percentage: hydrophobic microcapsule is 0.2%, cement is 17.8%, aggregate is 74.8% (wherein fine aggregate is 21.5%, coarse aggregate is 53.3%), water is 7.2%.

[0049] The requirements for raw materials and the preparation method of the impermeable concrete in this example are the same as in Example 1, the difference is that the capsule wall is made of vinyl polysilsesquioxane and polystyrene composite material, and the hydrophobic material is made of tetraethylene Oxysilane.

[0050] The test method of the cement concrete specimen of this embodiment is the same as that of Example 1, and the test results are shown in Table 1-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com