A kind of rust inhibitor sustained-release microcapsule and preparation method thereof

A technology of slow-release microcapsules and rust inhibitors, which is applied in the field of slow-release microcapsules for rust inhibitors and its preparation, and rust inhibitors for concrete steel bars. It can solve the problems of short anti-corrosion period of microcapsules and unsuitable wall materials for concrete systems, etc. , to achieve the effect of dense concrete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

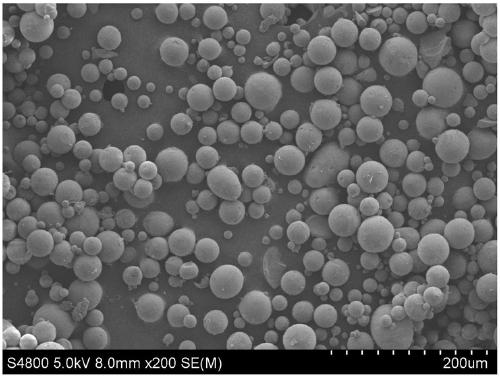

Image

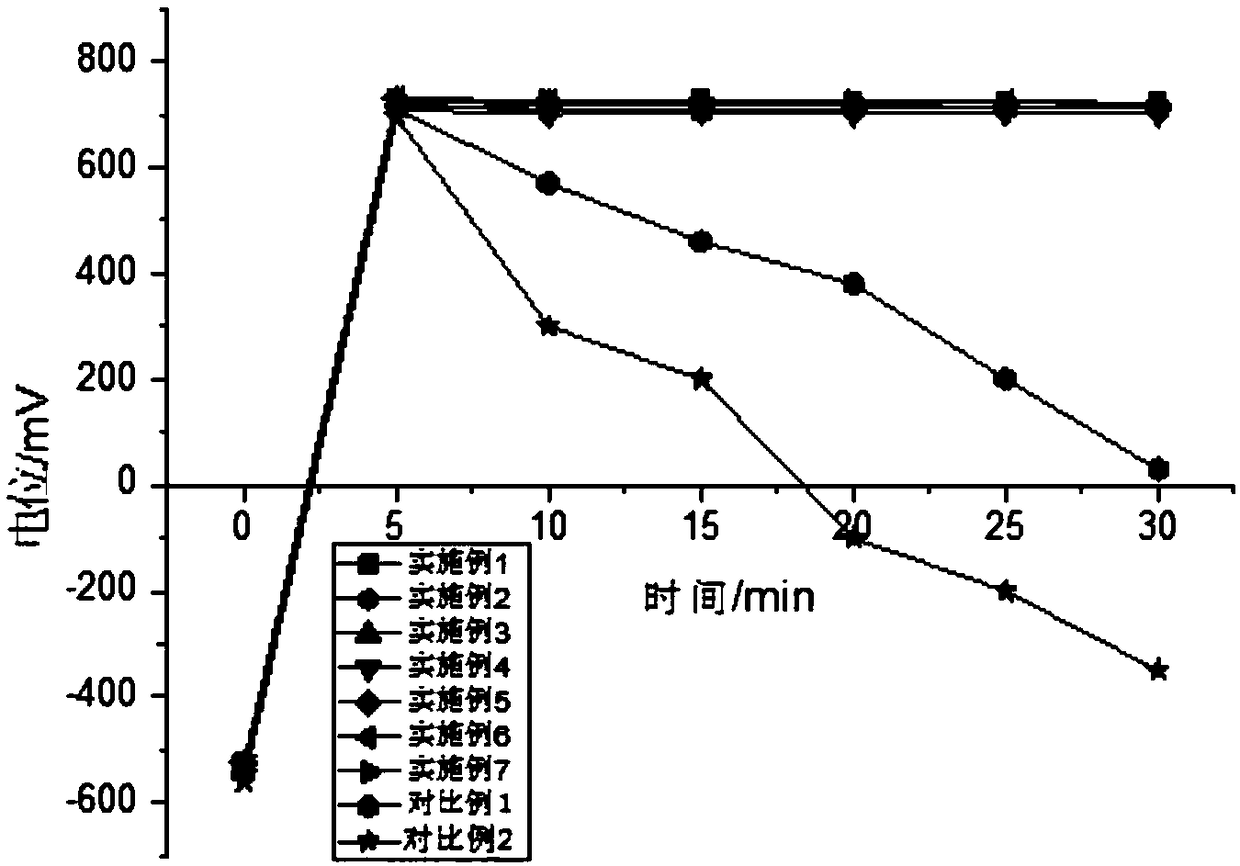

Examples

Embodiment 1

[0026] The present embodiment provides a kind of rust inhibitor sustained-release microcapsules, in terms of mass percentage, emulsifier mass concentration is 2%, trimethylsilyl polysilsesquioxane, polymethyl methacrylate polymer and mono The amount of sodium fluorophosphate added is 1:1:5 by mass ratio.

[0027] Based on the raw material formula of this embodiment, the specific preparation process of the rust inhibitor slow-release microcapsules of this embodiment is as follows:

[0028] Step 1, taking 4g of Span 80 and dissolving it in 200ml of liquid paraffin to obtain a continuous phase with an emulsifier mass concentration of 2%;

[0029] Step 2, respectively weigh 2g of trimethylsilyl polysilsesquioxane and 2g of polymethyl methacrylate polymer and dissolve them in 20ml of organic solvent methylene chloride, stir to make it completely dissolved, and add 10g of fine polysilsesquioxane to it. Sodium monofluorophosphate powder with a density of 200 meshes, stirred evenly, ...

Embodiment 2

[0033] This embodiment provides a kind of rust inhibitor slow-release microcapsules, in terms of mass percentage, emulsifier mass concentration is 0.5%, vinyl polysilsesquioxane, polymethyl methacrylate polymer and sodium monofluorophosphate The addition amount is 2:1:10 by mass ratio.

[0034] In this example, the requirements for raw materials and the preparation method of rust inhibitor slow-release microcapsules are the same as in Example 1, except that the emulsifier is Span 60, and the fineness of sodium monofluorophosphate powder is 100 mesh. The high-speed shear rate is 800r / min, and the shear time is 30min.

Embodiment 3

[0036] This embodiment provides a kind of rust inhibitor slow-release microcapsules, in terms of mass percentage, the mass concentration of emulsifier is 1%, the addition amount of methyl polysilsesquioxane, polystyrene polymer and sodium monofluorophosphate The mass ratio is 1:2:6.

[0037] In this example, the requirements for raw materials and the preparation method of rust inhibitor slow-release microcapsules are the same as those in Example 1, except that the emulsifier is Span 40, and the fineness of sodium monofluorophosphate powder is 300 mesh. The high-speed shear rate is 1000r / min, and the shear time is 15min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com