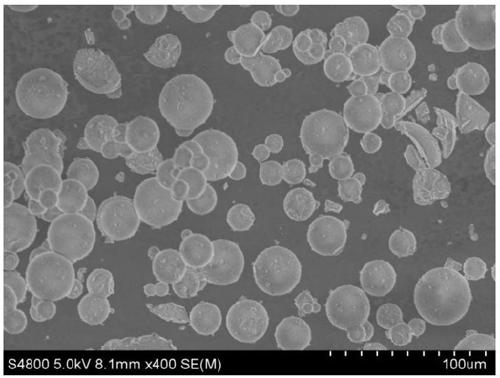

A kind of hydrophobic microcapsule and preparation method thereof

A technology of microcapsules and hydrophobic materials, applied in the field of road materials, can solve the problems of affecting the performance of concrete, having no obvious chemical effect, affecting the strength and durability of cement concrete, and achieving the effect of improving mechanical properties and improving impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a kind of hydrophobic microcapsule, wherein, the addition amount of polymethyl methacrylate polymer, hydrophobic material and cage type silsesquioxane is 1:1:0.001 by mass ratio;

[0035] The mass concentration of the emulsifier in the water phase is 1%.

[0036] Based on the raw material formula of this embodiment, the specific preparation process of the hydrophobic microcapsules of this embodiment is as follows:

[0037] Step 1, weigh 2g of gelatin and dissolve it in 200ml of deionized water, heat and stir until it is completely dissolved, and obtain an aqueous phase with an emulsifier mass concentration of 1%;

[0038] Step 2, weigh 2g of polymethyl methacrylate polymer and 2g of methyl silicone oil and dissolve in 20ml of organic solvent methylene chloride, stir to dissolve completely, then add 0.002g of silanol polysilsesquioxane to it , stir evenly, and the solution formed is an oil phase;

[0039] Step 3: Slowly add the oil phase to the...

Embodiment 2

[0057] This example provides a kind of hydrophobic microcapsule, wherein, the addition amount of polystyrene, hydrophobic material and cage silsesquioxane is 2:2:0.005 by mass ratio;

[0058] The mass concentration of the emulsifier in the water phase is 2%.

[0059] The requirements for raw materials and the preparation method of hydrophobic microcapsules and cement concrete in this example are the same as those in Example 1.

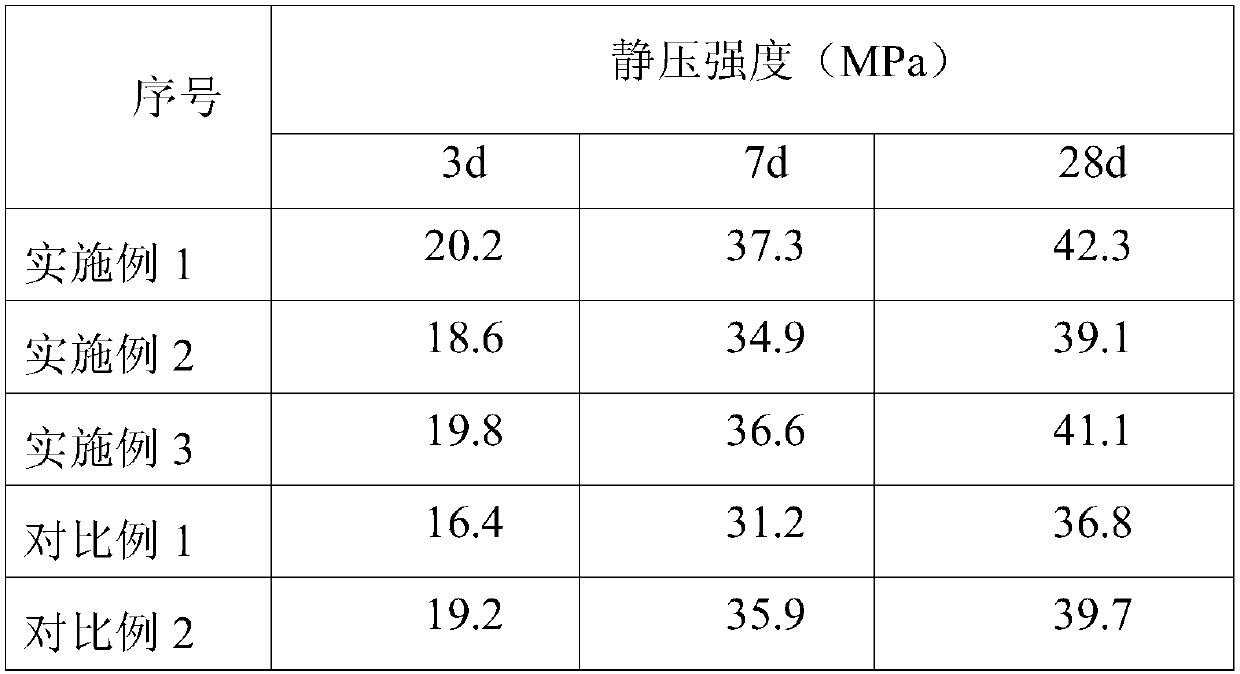

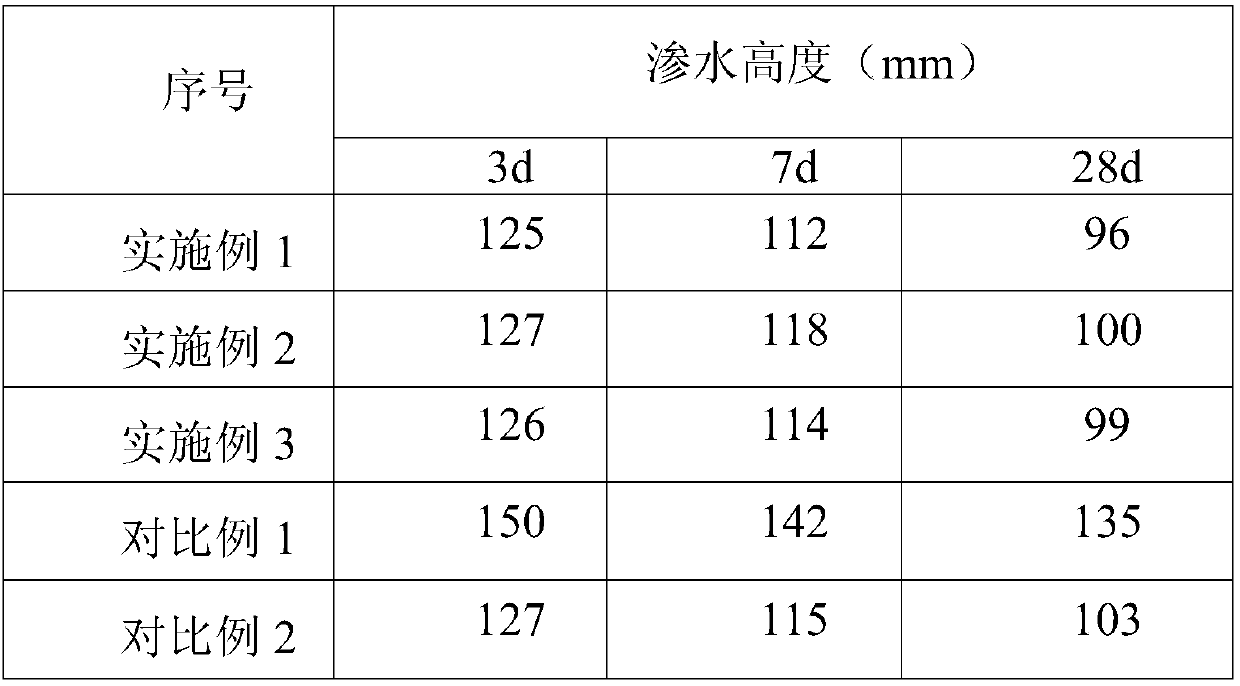

[0060] The test method of the cement concrete specimen of this embodiment is the same as that of Example 1, and the test results are shown in Tables 1-3.

Embodiment 3

[0062] This example provides a hydrophobic microcapsule, wherein the amount of polystyrene, hydrophobic material and cage silsesquioxane added is 1:1:0.001 by mass ratio;

[0063] The mass concentration of the emulsifier in the water phase is 1%.

[0064] In this embodiment, the requirements for raw materials and the preparation method of hydrophobic microcapsules and cement concrete are all the same as in Example 1. The difference is that the cage-type silsesquioxane adopts vinyl polysilsesquioxane, and the hydrophobic The material is tetraethoxysilane.

[0065] The test method of the cement concrete specimen of this embodiment is the same as that of Example 1, and the test results are shown in Tables 1-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com