A microbial composite admixture for preparing self-dredging cement-based permeable bricks

A composite admixture, permeable brick technology, applied in microorganism-based methods, microorganisms, biochemical equipment and methods, etc., can solve problems such as high cost and impracticality, and achieve excellent compressive strength, small attenuation of water permeability coefficient, and water permeability. Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

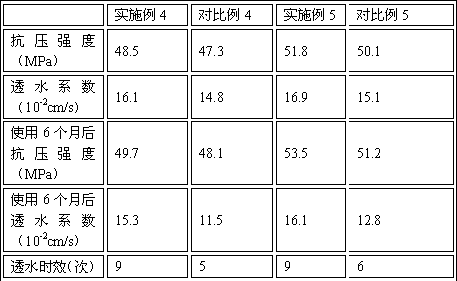

Examples

Embodiment 1

[0018] The present invention provides a microbial composite admixture for preparing self-dredging cement-based permeable bricks, inoculating bacterial strains Rhodococcus erythropolis and Bacillus cohnii in the basic medium in a conventional manner, The components of the basal medium are calculated in parts by mass: beef extract 5 g, peptone 8 g, sodium bicarbonate 0.8 g, sodium chloride 1.5 g, agar 9 g, deionized water 1000 ml, and 1mol / L NaOH solution The pH value was adjusted to 9.7, and then cultured at 27° C. on a water bath shaker at a speed of 100 rpm for 24 hours. After centrifuging the obtained mixed bacterial liquid on a centrifuge at a speed of 3000 rpm for 10 min, remove the supernatant and collect the wet cells of the strain with deionized water, and control the final concentration of the bacterial liquid at 3.2×10 7 cell / mL range. Add nutritional components and auxiliary components to the mixed bacterial solution to obtain the compound admixture, the content of...

Embodiment 2

[0020] The present invention provides a microbial composite admixture for preparing self-dredging cement-based permeable bricks, inoculating bacterial strains Rhodococcus erythropolis and Bacillus cohnii in the basic medium in a conventional manner, The components of the basal medium are calculated in parts by mass: beef extract 7 g, peptone 9 g, sodium bicarbonate 0.83 g, sodium chloride 1.6 g, agar 10 g, deionized water 1000 ml, and 1mol / L NaOH solution The pH was adjusted to 10.3. Subsequently, culture was shaken at 30° C. on a water bath shaker at a speed of 120 rpm for 36 hours. Centrifuge the obtained mixed bacterial liquid on a centrifuge at a speed of 3000rpm for 20min, remove the supernatant and collect the wet cells of the strain with deionized water, and control the final concentration of the bacterial liquid at 4.1×10 7 cell / mL range. Add nutrient components and auxiliary components to the mixed bacterial solution to obtain the compound admixture, the content of...

Embodiment 3

[0022] The present invention provides a microbial composite admixture for preparing self-dredging cement-based permeable bricks, inoculating bacterial strains Rhodococcus erythropolis and Bacillus cohnii in the basic medium in a conventional manner, The components of the basal medium are calculated in parts by mass: beef extract 8 g, peptone 10 g, sodium bicarbonate 0.85 g, sodium chloride 1.8 g, agar 12 g, deionized water 1000 ml, and 1mol / L NaOH solution The pH was adjusted to 10.9. Subsequently, culture was shaken at 29° C. on a water bath shaker at a speed of 150 rpm for 48 hours. Centrifuge the obtained mixed bacterial liquid on a centrifuge at a speed of 4000rpm for 20min, remove the supernatant and collect the wet cells of the strain with deionized water, and control the final concentration of the bacterial liquid at 4.9×10 7 cell / mL range. Add nutritional components and auxiliary components to the mixed bacterial liquid to obtain the compound admixture, the content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com