Flexible display device and method for preparing the same

A flexible display device and flexible technology, applied in the direction of final product manufacturing, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of reducing the overall bending deformation of the screen, increasing the bending strength of the screen, and poor film formation. , to achieve the effect of improving reliability and use effect, good flexible bending effect, and improving bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

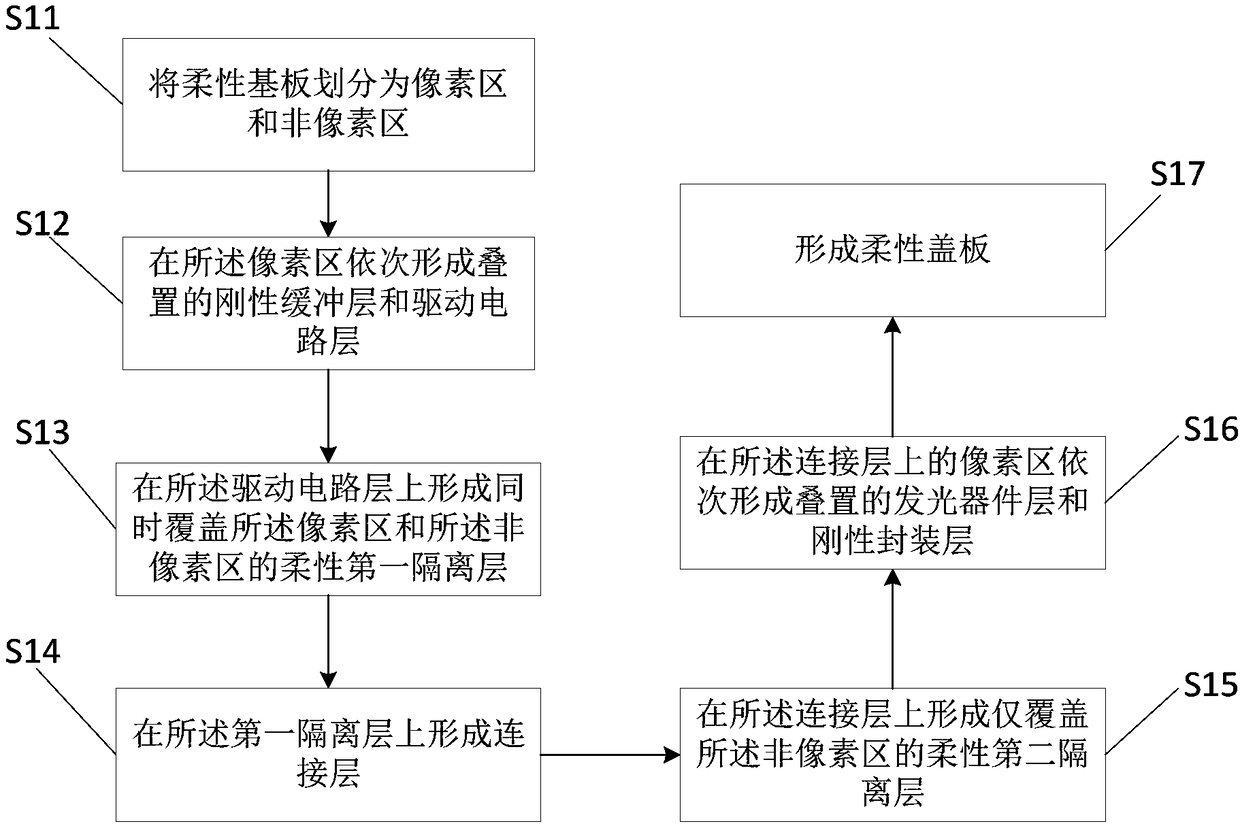

[0052] This embodiment provides a method for preparing a flexible display device, such as Figure 2-8 shown, including the following steps:

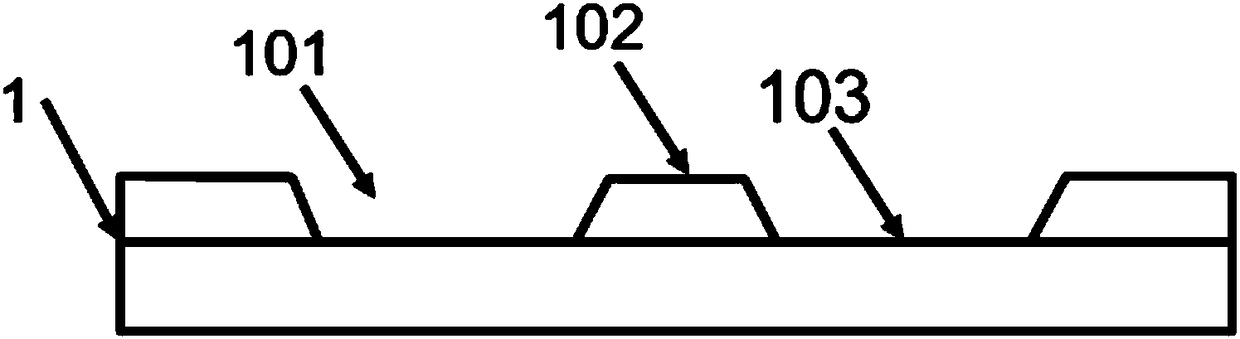

[0053] Step S11 , dividing the flexible substrate 1 into a pixel area 101 and a non-pixel area 102 .

[0054] Specifically, such as Figure 3-4 As shown, the flexible substrate 1 can be divided into a stacked two-layer structure, and a plurality of grooves 103 are formed on the upper flexible substrate 1 through a patterning process, and the region of the groove 103 is the pixel region 101, and the rest of the region is the non-pixel region. District 102. On the one hand, the recognition degree of the pixel area 101 and the non-pixel area 102 is improved, which is conducive to accurately distinguishing the pixel area 101 and the non-pixel area 102 during the preparation process, improving the preparation accuracy and reducing the difficulty of preparation; on the other hand, thinning The overall thickness of the display device is redu...

Embodiment 2

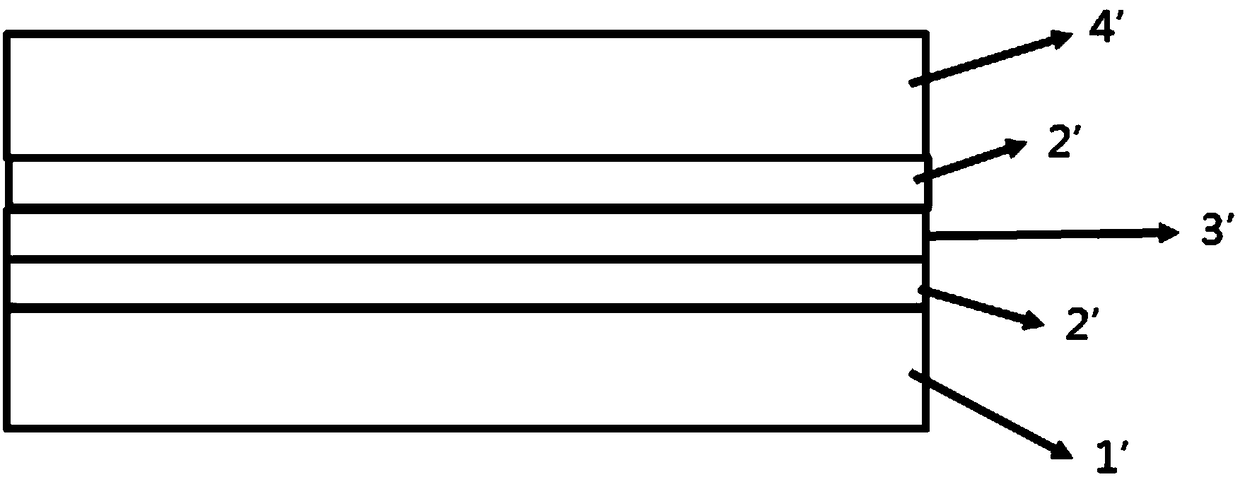

[0079] This embodiment provides a flexible display device prepared according to the preparation method in Embodiment 1, such as Figure 3-8 As shown, it includes a flexible substrate 1, a rigid buffer layer 2, a driving circuit layer 3, a flexible first isolation layer 4, a connection layer 5, a flexible second isolation layer 6, a light emitting device layer 8, a rigid packaging layer 9 and a flexible cover plate 10 .

[0080] The flexible substrate 1 is divided into a pixel area 101 and a non-pixel area 102 , and the rigid buffer layer 2 and the driving circuit layer 3 are sequentially stacked in the pixel area 101 of the flexible substrate 1 . The rigid buffer layer 2 can be an inorganic non-metallic material layer, generally, materials such as silicon nitride and silicon oxide can be used.

[0081] The flexible first isolation layer 4 is formed on the driving circuit layer 3 and covers the pixel area 101 and the non-pixel area 102 at the same time.

[0082] The connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com