Flexible supercapacitor based on carbon-based composite electrode and preparation method

A technology for supercapacitors and composite electrodes, which is applied in the manufacture of hybrid/electric double-layer capacitors, capacitor manufacture, electrolytic capacitors, etc., can solve problems such as difficulty in implementation, and achieve improved work reliability, high ionic conductivity, and good flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

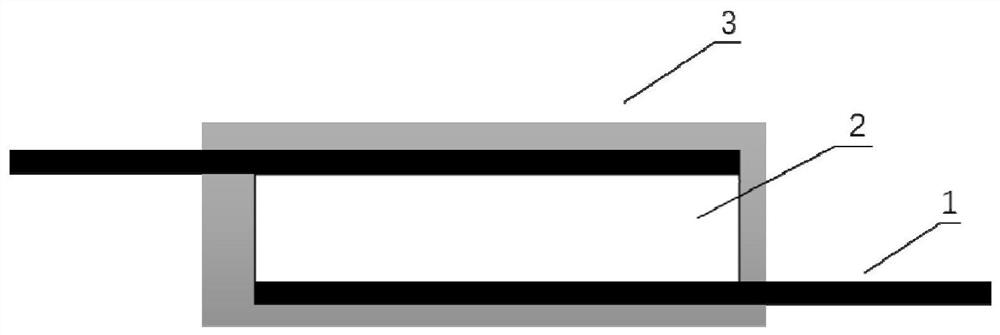

[0038] refer to figure 1 , the flexible supercapacitor of this embodiment includes carbon fiber / conductive graphite / graphene / MnO 2 Composite electrode 1, PVA gel solid electrolyte 2 and flexible PDMS package 3. After both sides of the PVA gel solid electrolyte 2 are covered with the composite electrodes to form a sandwich structure, PDMS flexible packaging is performed, and electrodes are drawn out during the packaging process as charging and discharging ports.

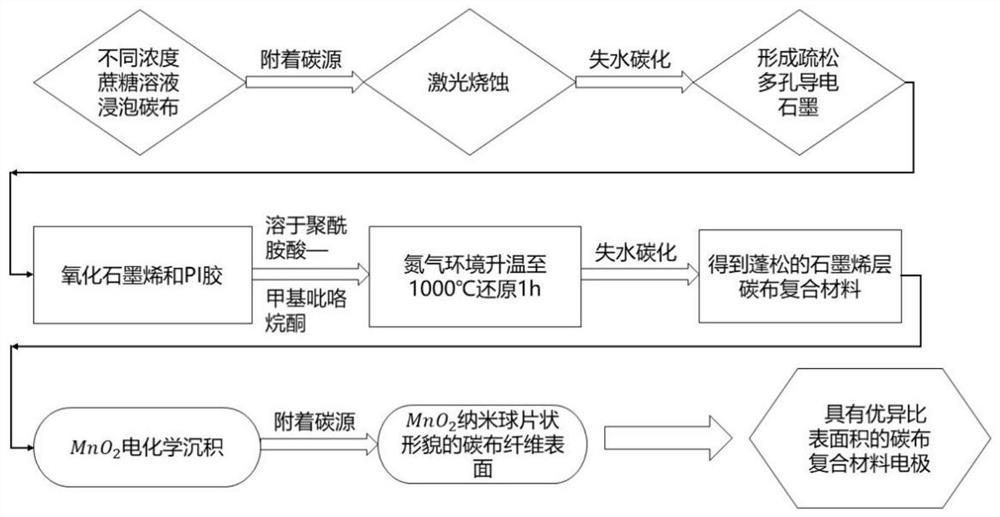

[0039] The concrete preparation process of this embodiment:

[0040] (1) Put 2×5cm 2 The carbon cloth was ultrasonically cleaned with acetone, deionized water, and ethanol for 90 minutes, and dried at 90°C;

[0041] (2) Arrange the cleaned carbon in a sucrose solution of sucrose: deionized water = 1:5, dry at 90°C, and perform laser ablation at 50% laser power and engraving depth of 10.0;

[0042] (3) Dissolve graphene oxide and PI glue in polyimide acid-methylpyrrolidone at a ratio of 1:1 to form a 30ml solution, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com