A Flexible Manipulator Based on Elastic Tube

A flexible manipulator and elastic tube technology, applied in the field of intelligent manipulators, can solve the problems of heavy rigid joints, poor flexible bending effect, and small bending curvature, etc., and achieve the effect of compact structure, high degree of freedom, and high compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

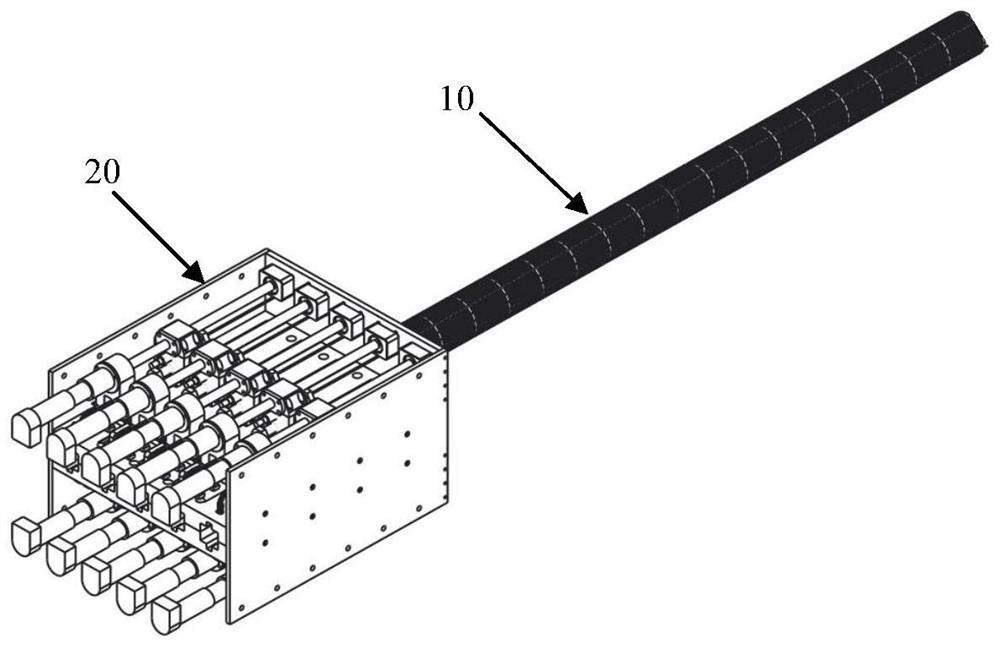

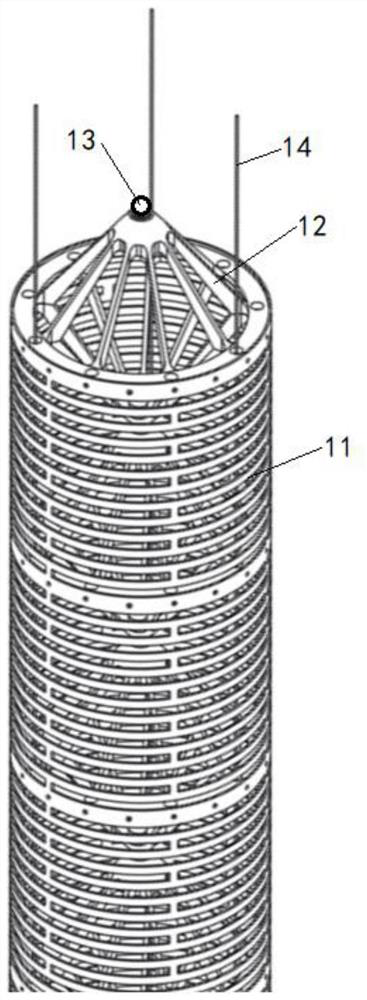

[0026] Such as figure 1 As shown, the preferred embodiment of the present invention discloses a flexible mechanical arm based on an elastic tube, including an arm segment mechanism 10 and a driving mechanism 20, combined with figure 2 , the arm segment mechanism 10 includes an elastic tube 11 and 5 joint segments that are sequentially connected to each other, the elastic tube 11 is integrally sleeved outside the 5 joint segments that are sequentially connected to each other, and each joint segment includes a plurality of joint modules 12, a plurality of A ball joint 13 and a plurality of ropes 14.

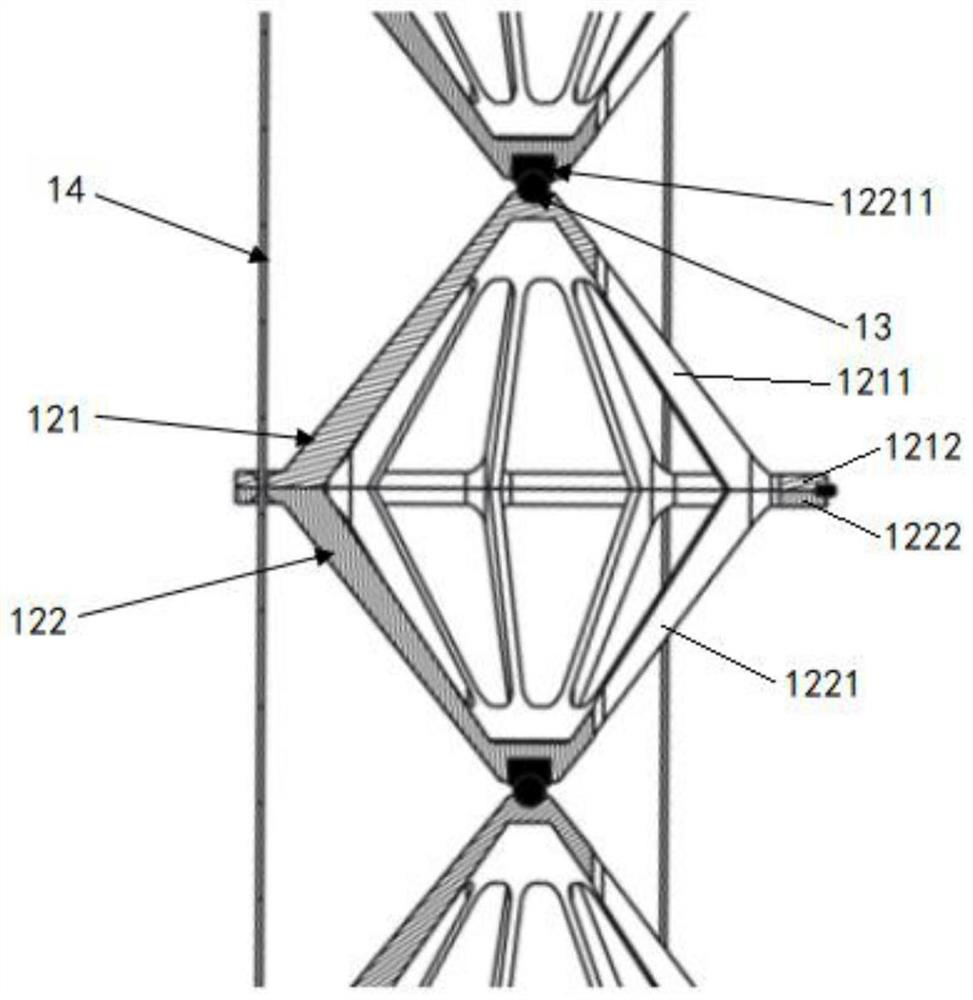

[0027] combine image 3 , the joint module 12 includes two interconnected joint units 121, 122, the joint unit 121 comprises a conical protrusion 1211 and a flange 1212 respectively, the joint unit 122 comprises a conical protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com