Touch screen manufacturing method, touch screen and displaying device

A touch screen and touch electrode technology, which is applied to devices for coating liquid on surfaces, input/output processes of data processing, instruments, etc., can solve the problem of increasing the roughness and process difficulty of metal grid electrodes and affecting touch screen touch performance. , low adhesion and other problems, to achieve the effect of improving light transmittance, not easy to open circuit, and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for manufacturing a touch screen, including:

[0046] Step S10: modifying the surface of the substrate to make the surface of the substrate hydrophilic.

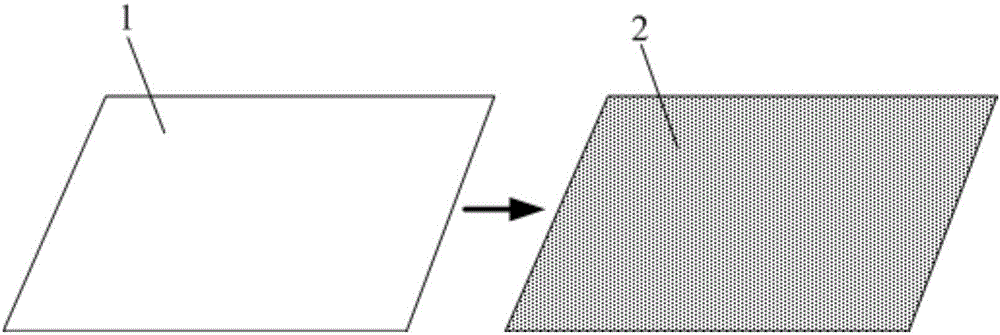

[0047] This step specifically includes: Step S101: On the substrate 1 of polyurethane material (PET), coat the organic silicon anti-fog transparent coating 2 of hydrophilicity (such as figure 2 shown).

[0048] Wherein, the coating thickness of the hydrophilic silicone anti-fog transparent coating 2 is 1-3 μm. It should be noted that the substrate 1 can also be made of other polymer transparent and flexible materials, such as PMMA (polymethyl methacrylate) or PVC (polyvinyl chloride).

[0049] Step S102: Curing the hydrophilic silicone anti-fog transparent coating 2 at a temperature of 90° C. to 110° C.

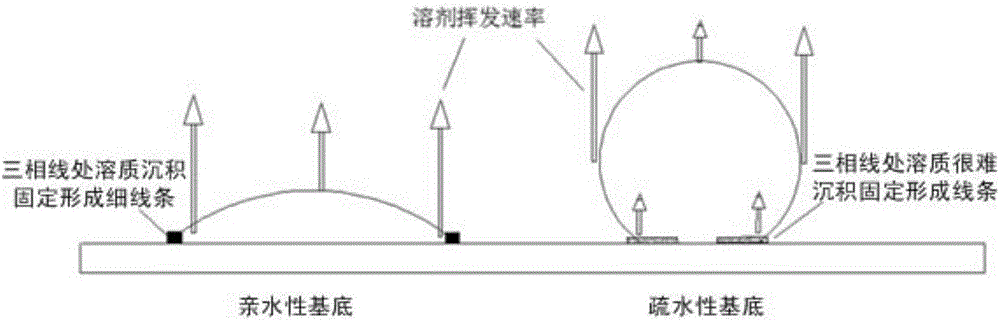

[0050]The surface of the substrate 1 is modified by coating the hydrophilic silicone anti-fog transparent coating 2, which can increase the hydrophilicity of the surface of the o...

Embodiment 2

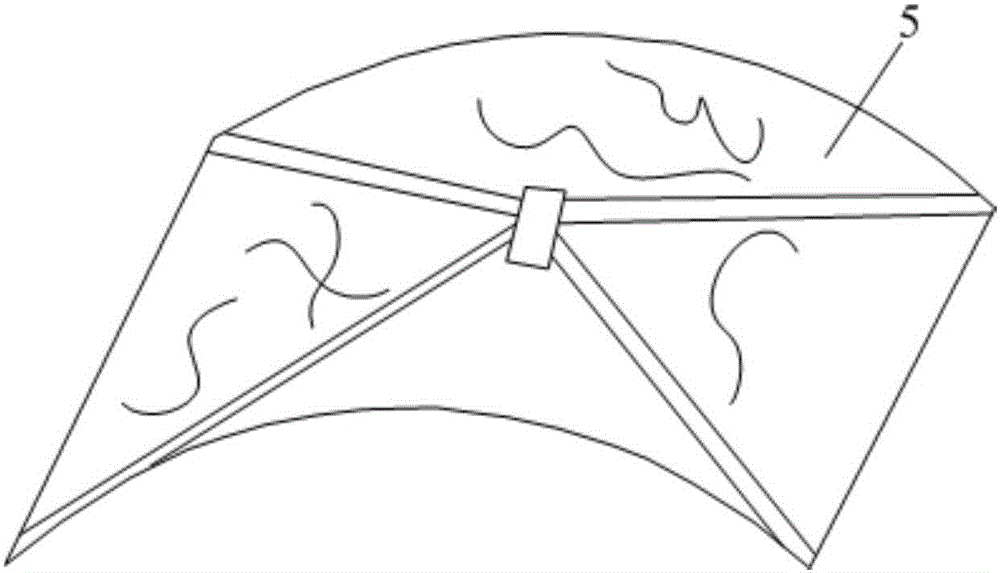

[0062] This embodiment provides a touch screen, which is prepared by the preparation method in Embodiment 1. like Figure 7 As shown, the substrate 1 and the touch electrodes 4 formed on the substrate 1 are included. The surface of the substrate 1 is hydrophilic; the touch electrodes 4 are made of graphene composite nano-silver material, and the touch electrodes 4 are grid-shaped.

[0063] Preferably, the substrate 1 is made of polyurethane material, the surface of the substrate 1 is formed with a hydrophilic silicone anti-fog transparent coating 2, and the line width of the touch electrode 4 is greater than or equal to 3 μm and less than or equal to 5 μm. The hydrophilic silicone anti-fog transparent coating 2 can make the hydrophobic substrate 1 have good hydrophilicity, so that the graphene composite nano-silver paste can be printed on the substrate by inkjet under the effect of "coffee ring" Lines with a thinner line width are formed on the substrate 1, which not only imp...

Embodiment 3

[0066] This embodiment provides a display device, including the touch screen in Embodiment 2.

[0067] By adopting the touch screen in Embodiment 2, not only the light transmittance of the display device is improved, but also the touch performance of the display device is improved.

[0068] The display device provided by the present invention can be any product or component with a display function, such as a liquid crystal panel, a liquid crystal TV, a monitor, a mobile phone, a navigator, and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com