Ultra-thick 5G antenna PCB module processing method

A module processing, 5G technology, applied in the processing of insulating substrates/layers, multi-layer circuit manufacturing, electrical components, etc., can solve problems such as time-consuming, accuracy deviation, and signal debugging difficulties, and improve accuracy and product quality , prevent precision deviation, reduce the effect of process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

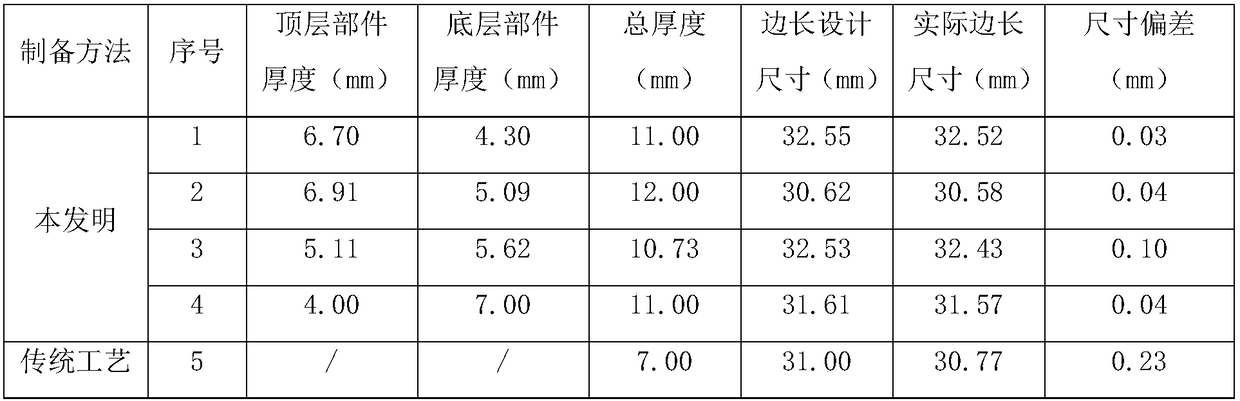

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

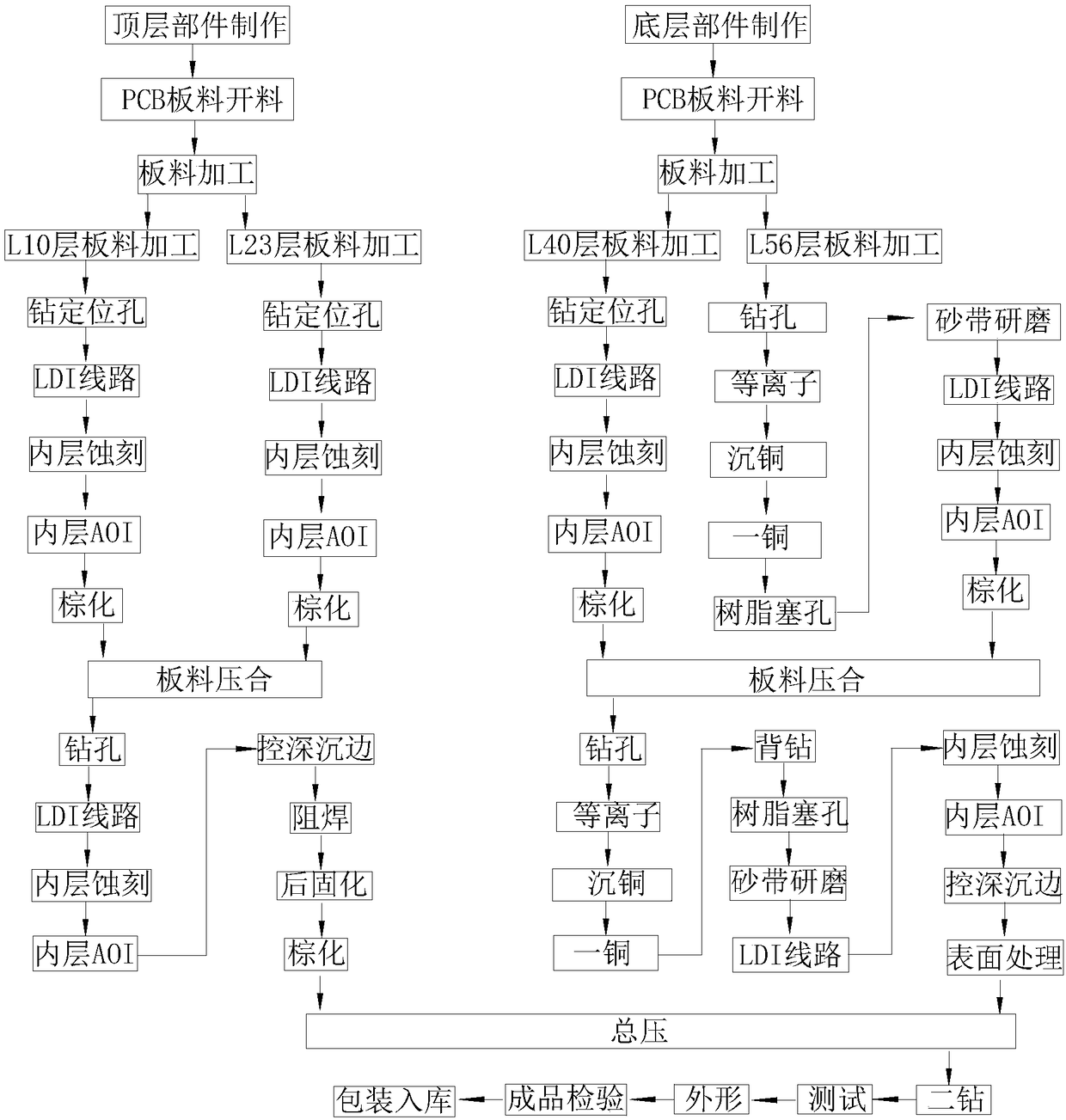

[0035] Such as figure 1 As shown, a processing method for an ultra-thick 5G antenna PCB module includes the following processing steps:

[0036] Step 1: Top layer parts making:

[0037] Step 1.1, material cutting: Cutting the PCB substrate according to the design structure, that is, two inner layer materials of L10 and L23;

[0038] Step 1.2, sheet material processing: the L10 layer sheet material and the L23 layer sheet material are respectively subjected to drilling positioning holes, LDI lines, inner layer etching, inner layer AOI, and browning treatment;

[0039] Step 1.3, sheet pressing: press the L10 layer sheet and the L23 layer sheet processed in step 1.2 to obtain the L13 layer sheet, the thickness of the L13 layer sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com