Polymer resistance type humidity-sensitive element and preparation method thereof

A technology of humidity sensor and resistance type, which is applied in the field of polymer resistance type humidity sensor and its preparation, can solve the problems of low humidity and high resistance, achieve fast response speed, improve deliquescence resistance, and reduce resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

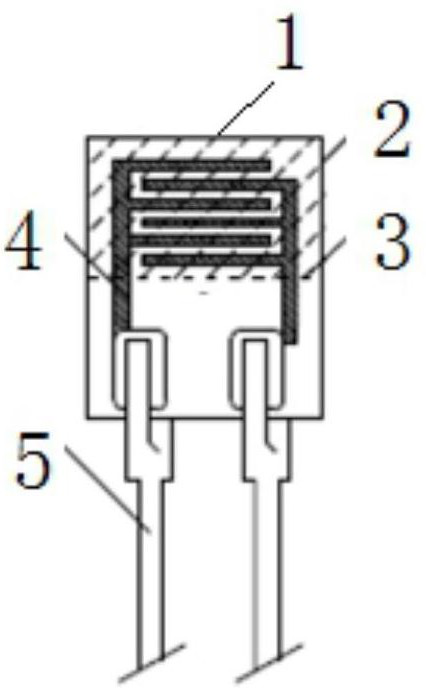

[0046] The preparation method of the polymer resistance type humidity sensor includes two parts: the preparation of the interdigital electrodes and the preparation of the moisture-sensitive film.

[0047] Among them, the preparation process of the interdigitated electrode is as follows:

[0048] The first step: using screen printing technology to prepare interdigitated electrodes, according to the mass ratio of ink: copper powder (8-10): 1, the ink is prepared into a paste; as a preference, ink: copper powder Mass ratio 9:1;

[0049] Step 2: Then inject the paste onto the No. 1 screen plate with part of the interdigitated electrode pattern, the pattern of the No. 1 screen plate corresponds to the printed lateral electrode, at an inclination angle of 35-45° and Scrape the paste under Newtonian pressure, make horizontal electrodes and dry them;

[0050] Step 3: Align the electrodes printed and dried in the second step with the No. 2 screen plate with a part of the interdigitat...

Embodiment 1

[0069] Embodiment 1: The preparation process of the interdigitated electrode of the polymer resistance type humidity sensor is as follows:

[0070] The first step: use screen printing technology to prepare interdigitated electrodes, according to the mass ratio of ink:copper powder is 8:1, the ink is prepared into a paste;

[0071] Step 2: Then inject the paste onto the No. 1 screen plate with part of the interdigitated electrode pattern, the pattern of the No. 1 screen plate corresponds to the printed lateral electrode, at an inclination angle of 35-45° and Scrape the paste under Newtonian pressure, make horizontal electrodes and dry them;

[0072] Step 3: Align the electrodes printed and dried in the second step with the No. 2 screen plate with a part of the interdigitated electrode pattern. The pattern of the No. 2 screen plate corresponds to the printed longitudinal electrode. Under the same conditions Scratch the paste, print the longitudinal electrodes and dry them;

[...

Embodiment 2

[0080] Example 2: The preparation process of the interdigitated electrode of the polymer resistance type humidity sensitive element is the same as that of Example 1, except that the mass ratio of ink: copper powder in the first step is adjusted to 9:1. The preparation process is also consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com