Multi-circle QFN package lead frame manufacturing method

A technology for encapsulating leads and frames, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve problems such as difficult to meet the use requirements, complicated preparation process, and low processing accuracy, so as to reduce damage and improve manufacturing Good precision and product uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific drawings and embodiments.

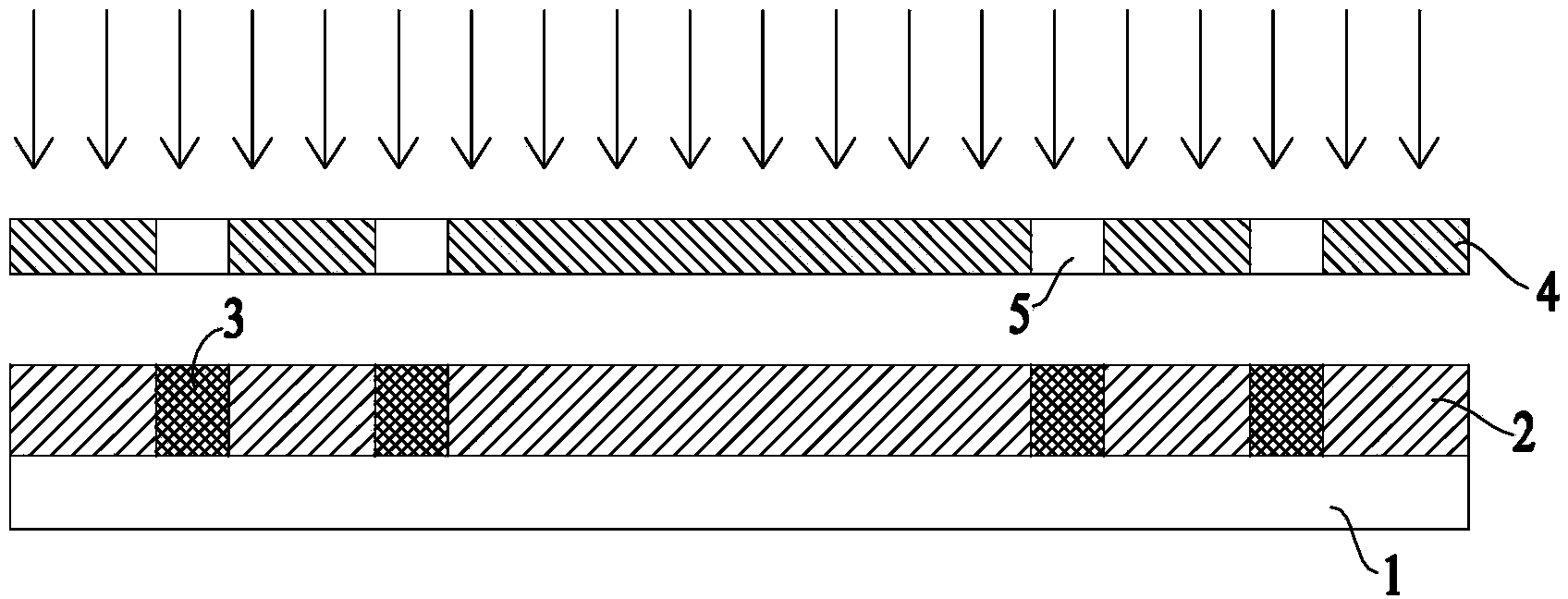

[0031] Such as Figure 1~Figure 9 Shown: in order to be able to prepare multi-circle QFN package lead frame conveniently, reduce processing cost, improve production precision and efficiency, the preparation method of package lead frame of the present invention comprises the following steps:

[0032] a. Provide the substrate 1, and set and form the required pin pattern 12 on the front surface of the substrate 1;

[0033] Such as Figure 1~Figure 4 As shown: in the embodiment of the present invention, the material of the substrate 1 includes copper. In order to obtain the pin pattern 12 on the substrate 1, the step a includes the following steps:

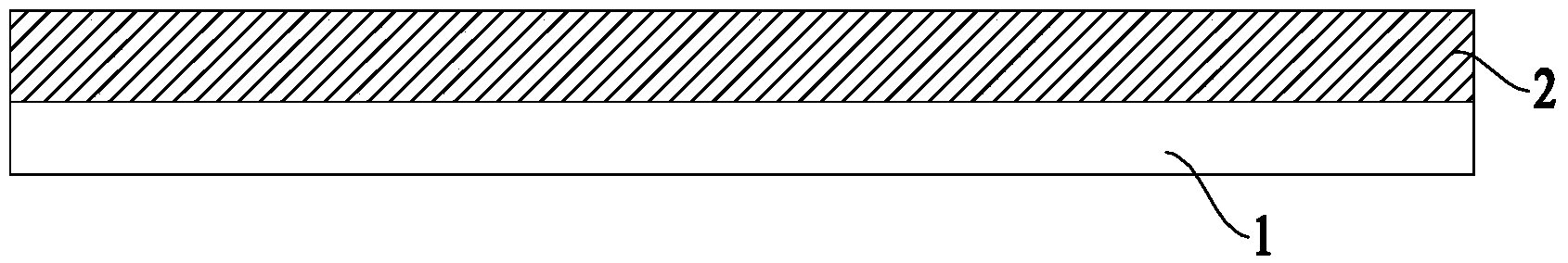

[0034] a1, providing the substrate 1, and setting the required dry film 2 on the front surface of the substrate 1;

[0035] The type of dry film 2 provided on the substrate 1 can be determined according to the requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com