Metal powder preparation device and method through vacuum induction melting and double-flow gas atomization

A technology of vacuum induction melting and atomizing metal, which is applied in metal processing equipment, transportation and packaging, etc. It can solve the problems of satellite powder formation, poor fluidity, and easy powder collision, etc., and achieve the effect of reducing formation and improving preparation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

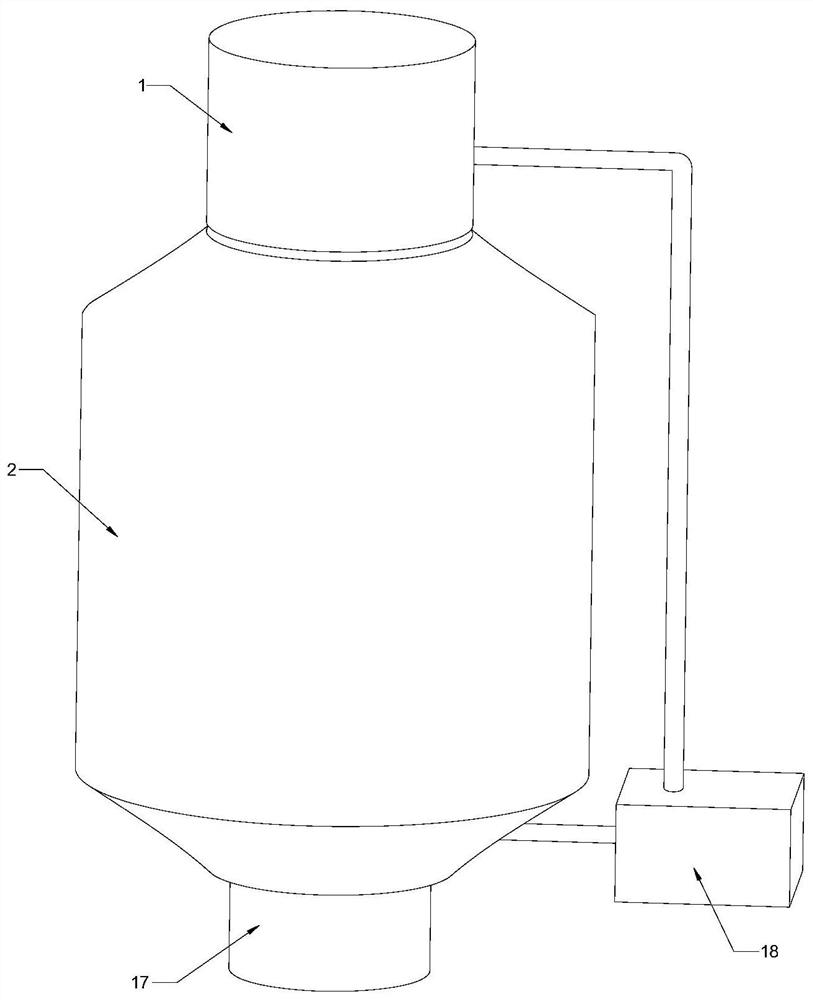

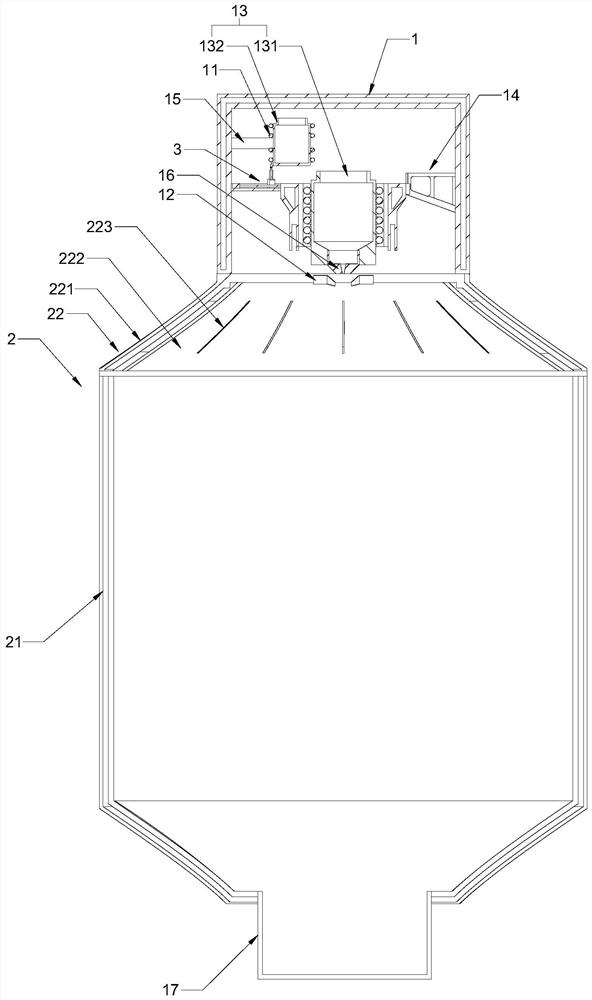

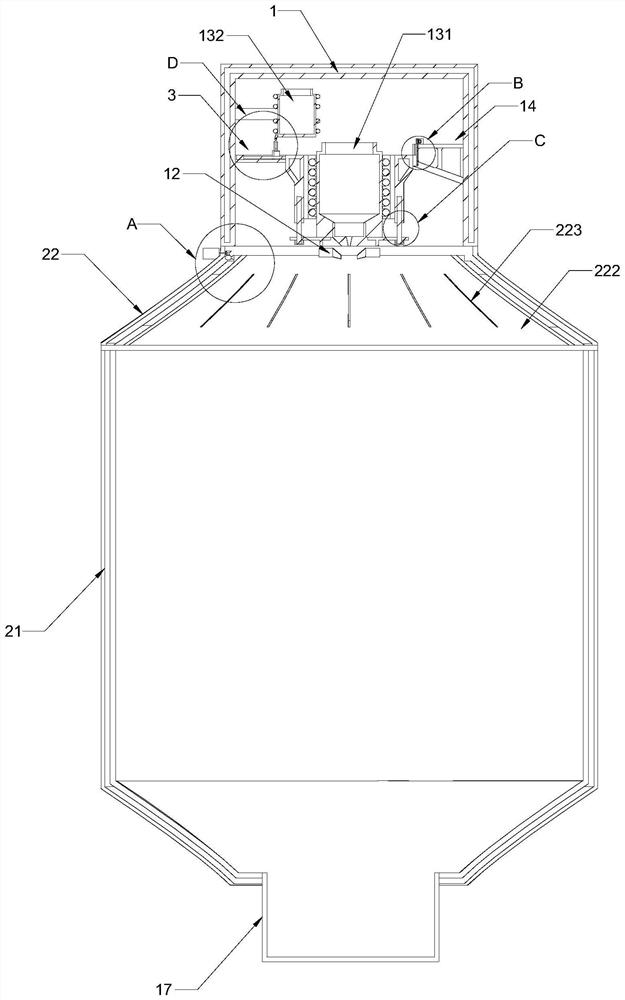

[0037] refer to figure 1 and figure 2 As shown, it is a specific embodiment of a vacuum induction smelting double-flow gas atomization metal powder device and method of the present invention, including a melting chamber 1 and an atomizing chamber 2 arranged below the melting chamber 1, the melting chamber 1 and the atomizing chamber 2 conduction, the smelting chamber 1 includes an induction coil 11, an atomizing nozzle 12 and a smelting crucible 13 for melting metal, and the smelting chamber 1 is provided with a mounting bracket 14 and a moving bracket 15, and the smelting crucible 13 includes a first A crucible 131 and a second crucible 132, the second crucible 132 is arranged on the mobile support 15, and the mobile support 15 is also provided with a turning mechanism 3 for controlling the turning of the second crucible 132, the first crucible 131 is arranged on the mounting bracket 14 and Vertically arranged, the first crucible 131 and the second crucible 132 are equipped...

Embodiment 2

[0043] It is a specific embodiment of a vacuum induction smelting double-flow gas atomization metal powder device and method of the present invention, the difference from Example 1 is that: refer to image 3 and Figure 4 , the compressed air chamber is also provided with an adjustment grid 4, the atomization chamber 2 is also provided with an adjustment mechanism 5 for controlling the position of the adjustment grid 4, and the adjustment grid 4 is provided with a number of grid openings 41 in a circular array along the central axis. The number of ports 41 is consistent with the number of air curtain ports 223. The adjustment mechanism 5 includes an adjustment motor 51, an adjustment ring gear 52 and a transmission assembly 53. The adjustment ring gear 52 is rotationally connected with the air curtain shell 222, and the adjustment motor 51 is arranged on the outer casing 221 The outer wall, the adjustment grid plate 4 is connected with the adjustment ring gear 52, the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com