Method for depositing core layer of optical fiber preform with gradient refractive index profile

A graded refractive index and optical fiber preform technology, which is applied in manufacturing tools, glass manufacturing equipment, etc., can solve problems such as uneven distribution of axial parameters, affecting optical performance of optical fibers, and deviation from ideal profiles, etc., to achieve implementability and operability Strong, improved preparation accuracy and effective rod length, simple and effective method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0040] For the convenience of introducing content of the present invention, some terms are defined:

[0041] Mandrel: a preform comprising a core and part of the cladding;

[0042] Flowmeter (Mass Flow Controller, MFC): Provide accurate reactants (such as GeCl 4 、C 2 f 6 etc.) gas flow stabilization device with automatic flow control;

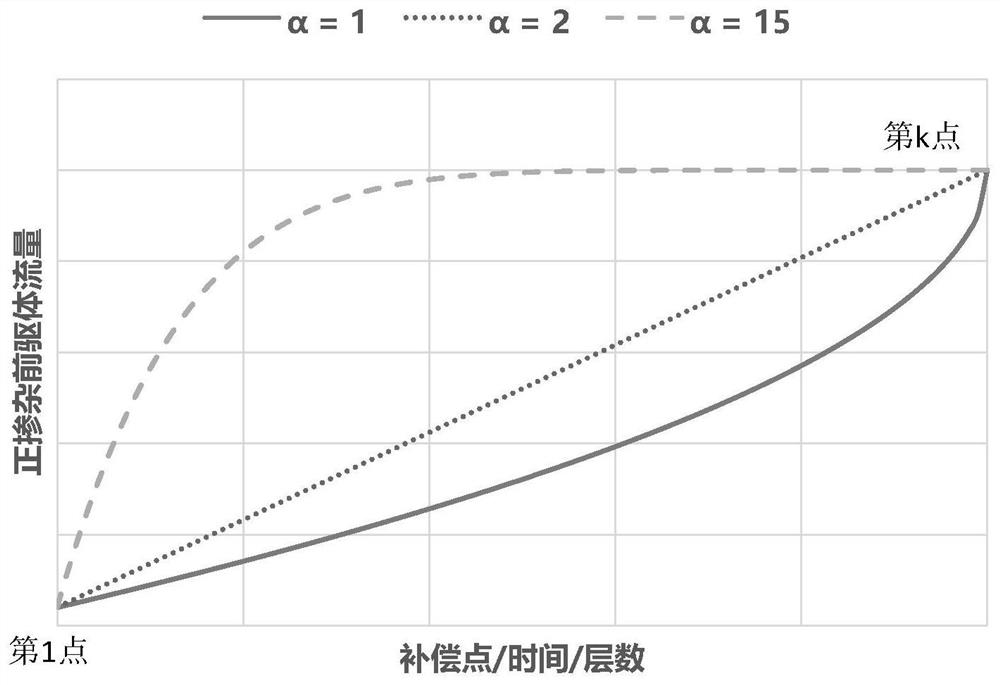

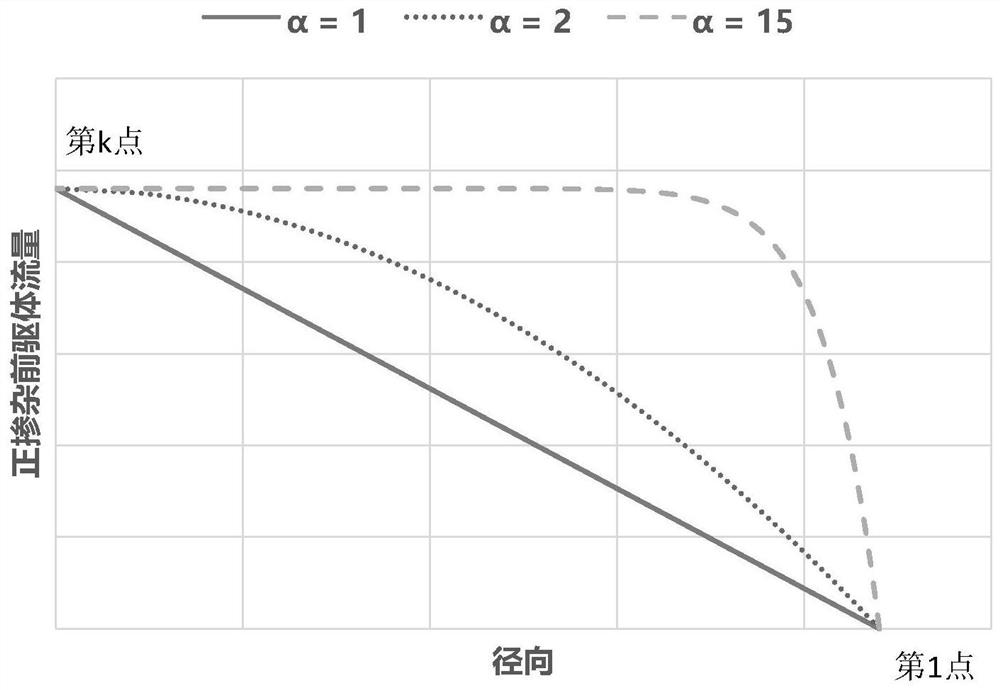

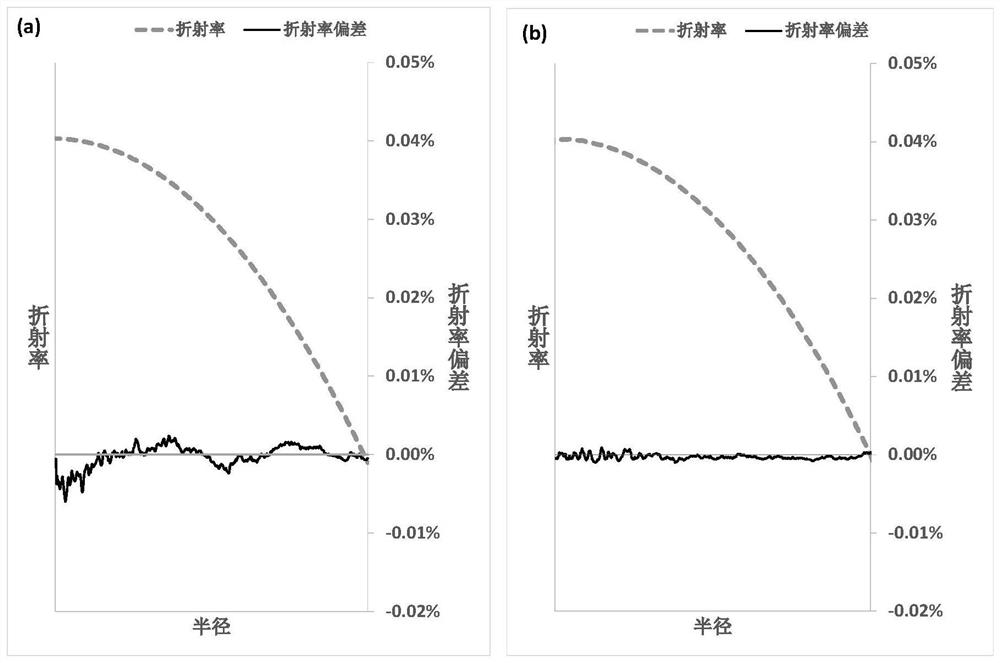

[0043] Doping deposition calibration: According to the dopant flow control data and the refractive index profile of the master rod, the software program is used to calculate the response relationship between the refractive index of the section and the dopant flow rate during the deposition process, and the ideal profile recalculated according to the above response relationship is required Flow rate, k×(m+1) flow c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com