Turret tool post indexing and positioning mechanism

A technology of indexing positioning and turret turret, which is applied to precision positioning equipment, metal processing machinery parts, tool holders, etc. It can solve the problems of low contact stiffness and low repeat positioning accuracy, so as to prolong the service life and improve positioning accuracy and contact stiffness, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] Embodiment: Below in conjunction with accompanying drawing, the present invention is further described:

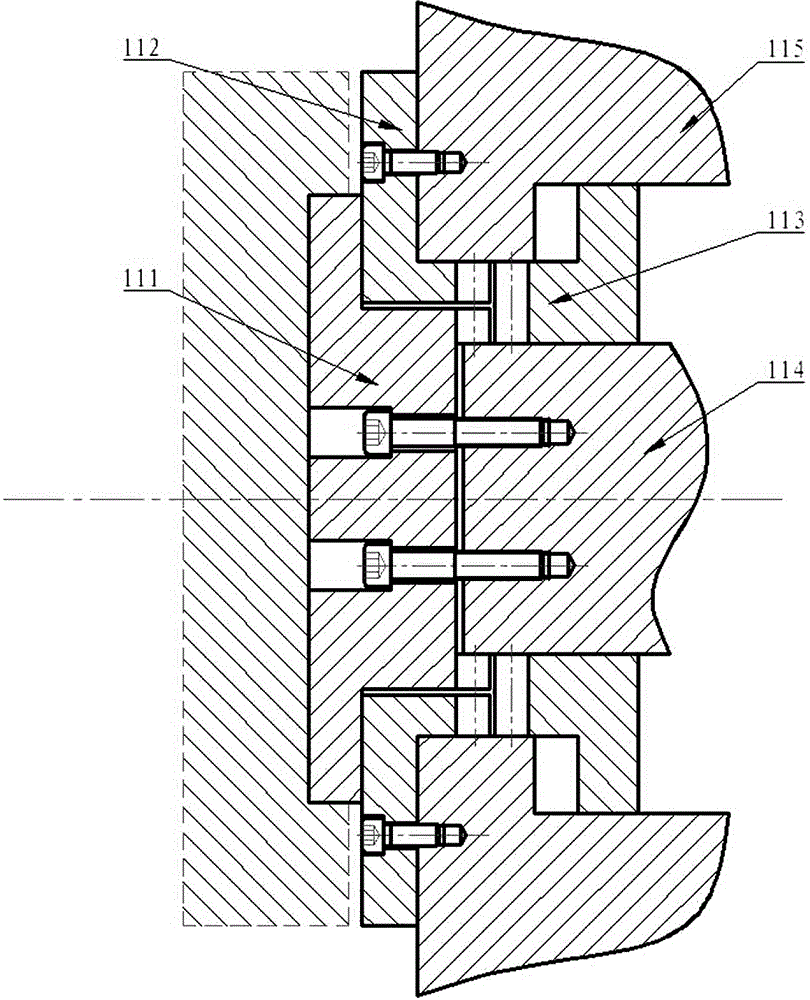

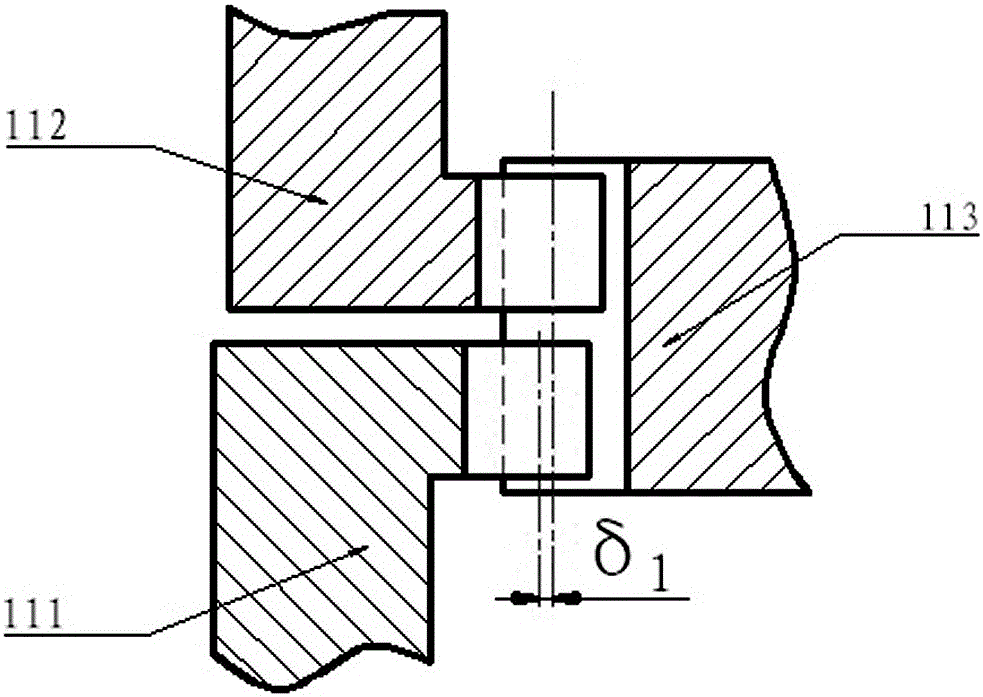

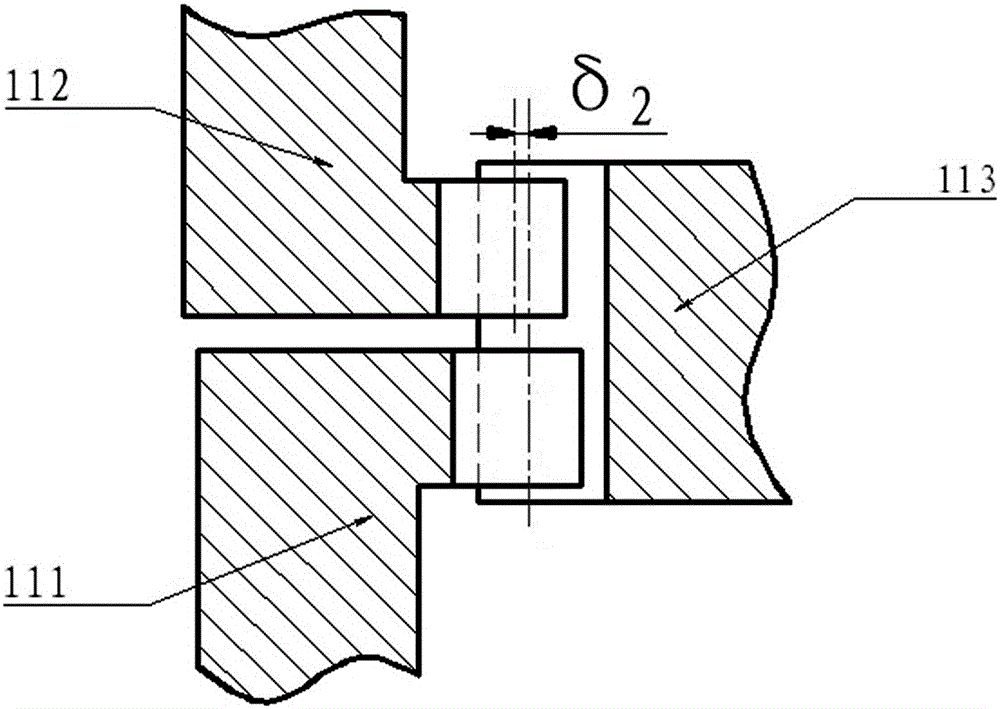

[0026] like Figure 1-3 Shown is the accompanying drawing of background technology, figure 1 Middle 111 is a moving toothed disc, 112 is a fixed toothed disc, 113 is formed by a locking toothed disc, 114 is a main shaft, and 115 is a casing.

[0027] like Figure 4 and Figure 5 As shown, the present invention provides a turret tool post indexing and positioning mechanism, including a main shaft 8 and a box body 3, the box body 3 is arranged around the main shaft 8, and the mechanism also includes a locking toothed disc 1, a positioning disc 4 and a movable tooth Disk 6; the movable toothed disk 6 is arranged on the front end of the main shaft 8, the cutter head 7 is installed on the movable toothed disk 6, the positioning disk 4 is arranged on the box body 3, the locking toothed disk 1 is arranged on the main shaft shaft body and can be positioned on the main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com