Device and method for preparing two-dimensional nanosheet material through cooperation of ball milling and cavitation

A technology for two-dimensional nanometer and preparation devices, which is applied in the field of preparation of two-dimensional nanosheet materials, can solve the problems of bulky equipment, bulky and bulky, and low work efficiency, and achieve the goal of considerable material preparation process, simple process, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

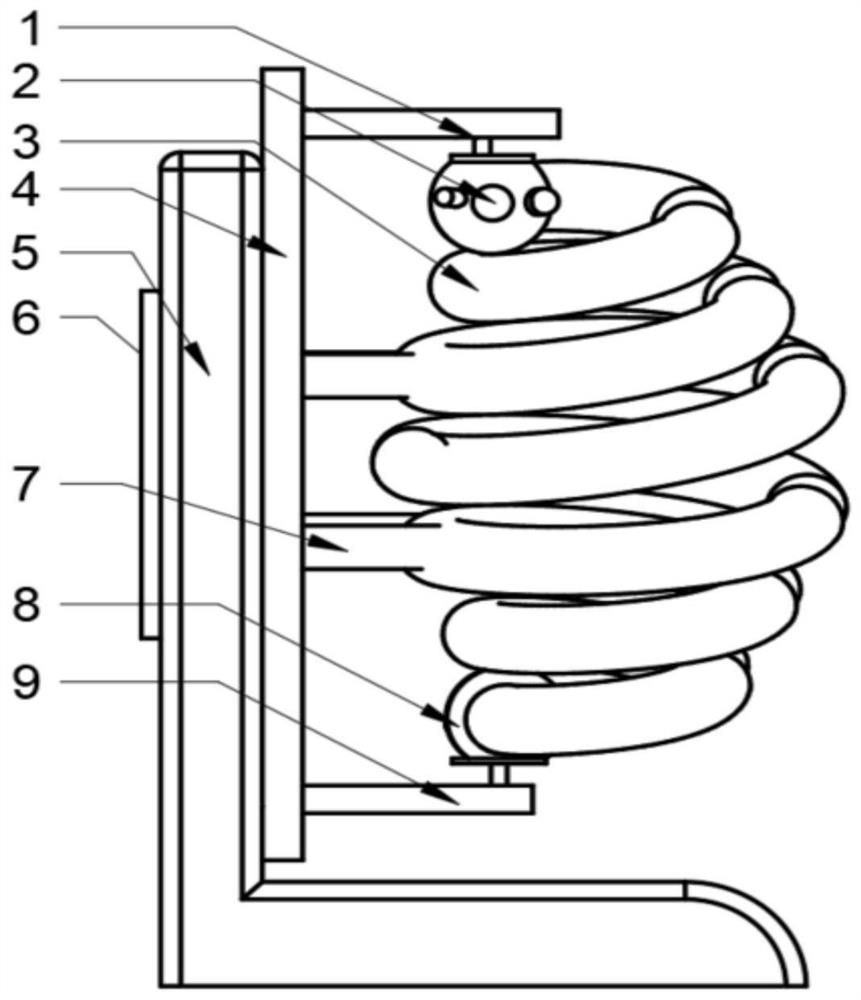

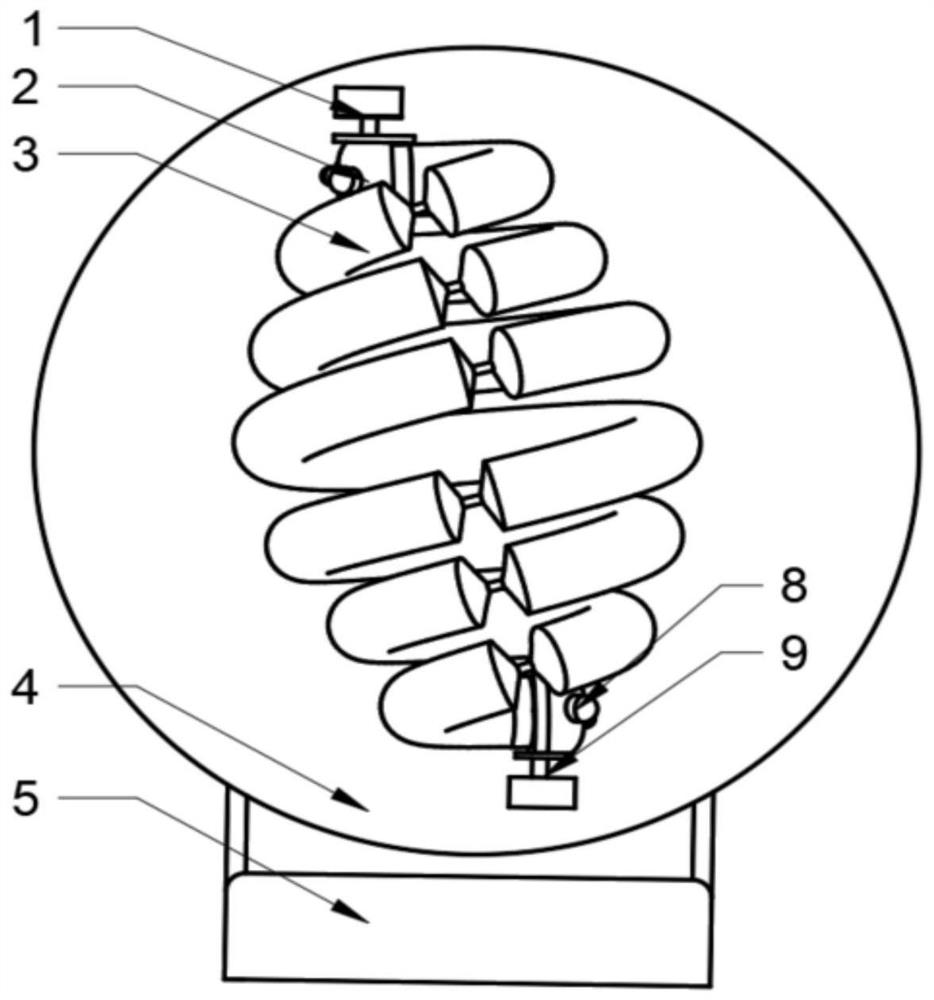

[0030] see figure 1 and figure 2 , a kind of ball milling and cavitation synergistic two-dimensional nano sheet material preparation device according to the present invention has a base 5 placed on the ground, the base 5 is an L-shaped solid structure, the L-shaped horizontal section contacts the ground, and the L-shaped The vertical section of the type is fixedly connected to the housing of the motor 6, the motor 6 is on the back of the rotating disk 4, the rotating disk 4 is a disk-shaped entity, and does not contact the base 5, and the central axes of the motor 6 and the rotating disk 4 are arranged horizontally , the output shaft of the motor 6 is fixedly connected to the center of the rotating disk 4 coaxially, and can drive the rotating disk 4 to rotate.

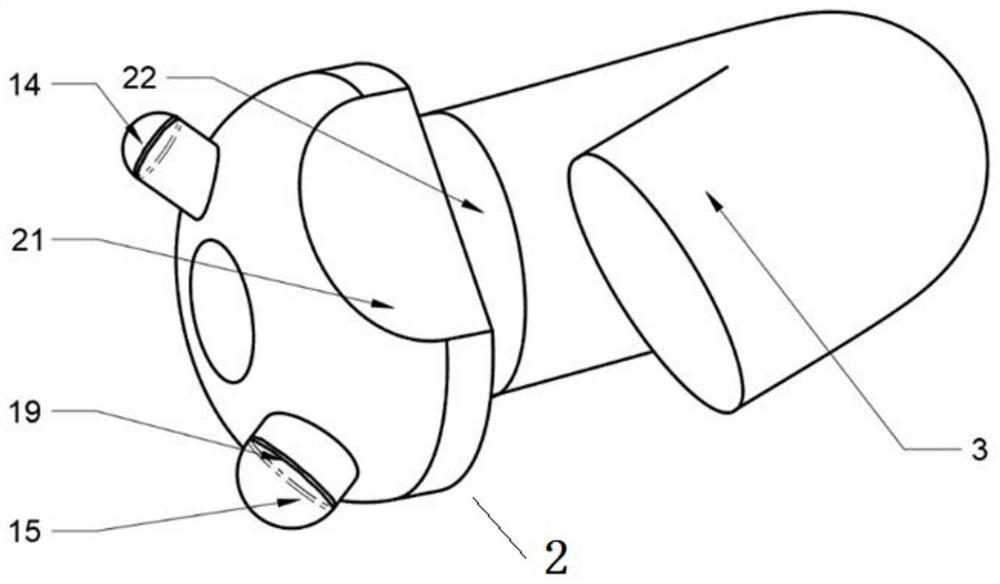

[0031] The motor 6 is on the back of the rotating disk 4, and a spiral container 3 is arranged on the front of the rotating disk 4. The spiral container 3 is fixed and welded to the rotating disk 4 through the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com