Layered buffer energy absorption structure body for EMAS (Engineered Material Arresting System) and preparation method

A structural and layered technology, applied in the direction of roads, special pavements, roads, etc., can solve the problems of structural damage of landing gear, no strength gradient, EMAS arresting effect can not take into account the weight difference, etc., to meet the arresting effect and safety. , The processing technology is simple, the effect of ensuring the blocking effect and blocking safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

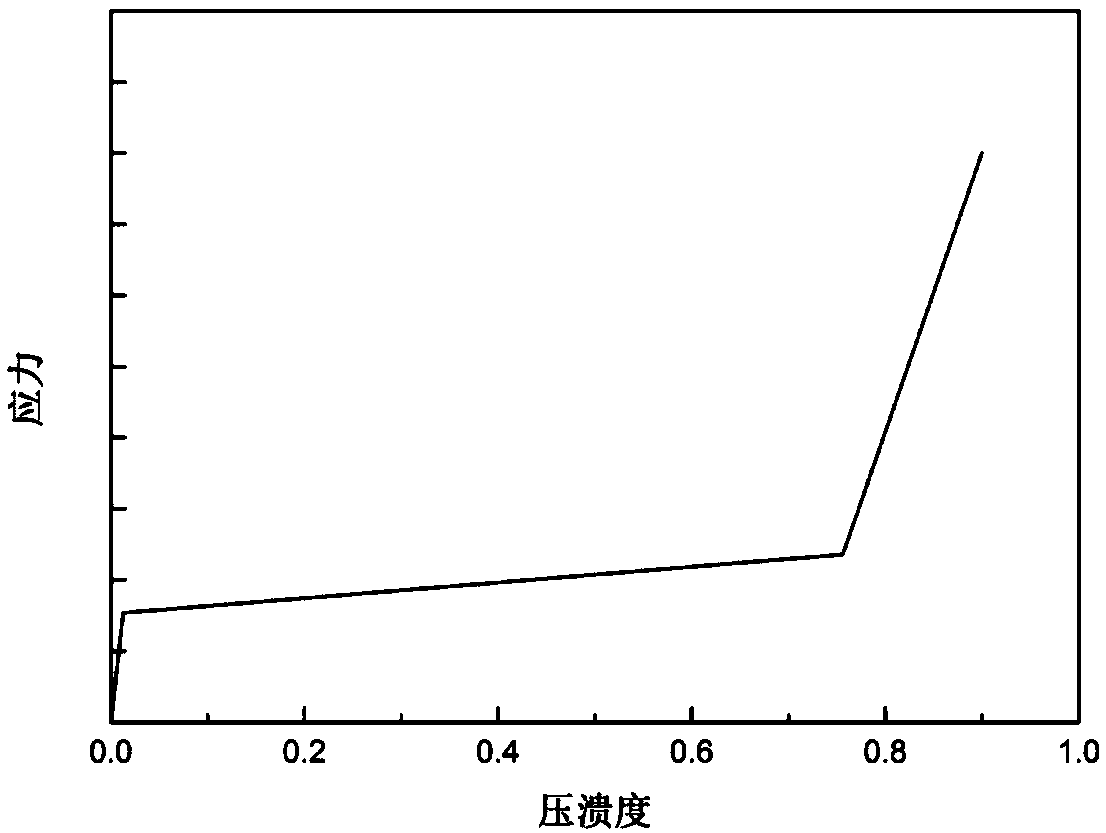

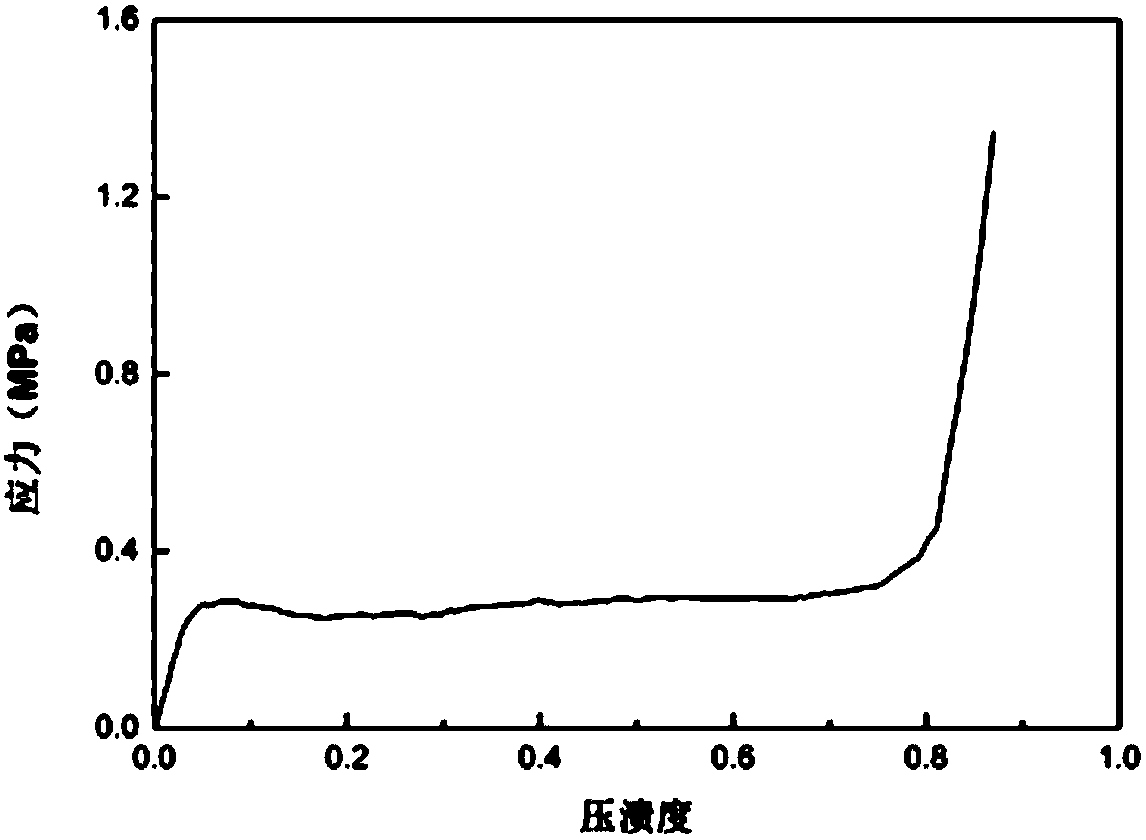

[0059] Embodiment 1 uses mechanical performance characteristics such as image 3 and Figure 4 The shown prefabricated foam concrete material is prepared into an EMAS unit body according to the prefabricated body bonding method and applied in the EMAS system.

[0060] The specific steps are:

[0061] 1) According to the methods described in Example 6 and Example 8 of our unit's published patent "A Silicate-Based Lightweight Foamed Concrete" (Application No.: 201710311732.6), the prefabricated body of the foamed concrete material is prepared as the upper layer and the lower layer, respectively. The dimensions are all length 1m×width 1m×height 25cm, the strength is 0.24MPa and 0.49MPa respectively, the maximum crushing degree is 0.72 and 0.74 respectively, and the stress-crushing degree curve is as follows image 3 and Figure 4 shown;

[0062] 2) Apply ordinary portland cement paste or silicone adhesive (Chengdu Tuoli Technology Co., Ltd., model TQ-100PN) evenly on the cont...

Embodiment 2

[0072] Example 2 A layered buffer energy-absorbing material with foamed concrete as the upper layer and silicone foam as the lower layer was prepared according to the layered pouring method, and applied to the EMAS system.

[0073] The specific steps are:

[0074] 1) According to the method described in Example 1 of our unit's published patent "A Silicone Foaming Composition and a Silicone Porous Foaming Material Prepared from the Foaming Composition" (Application No.: 201710010946.X) to prepare porous foam Foam silicone material, the thickness is 25cm, the strength is 0.54MPa, the maximum crushing degree is 0.83, and the stress-crushing degree curve is as follows Figure 11 shown;

[0075] 2) After the organic silicon material of the lower layer is cured, according to the method described in Example 6 of our company's published patent "A Silicate-based Lightweight Foamed Concrete" (application number: 201710311732.6), pour foam concrete directly on the organic silicon materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com