Blocking system and blocking method for tailing-pond flood discharge tower

A technology for tailings ponds and floods, applied in water conservancy projects, marine engineering, construction, etc., can solve the problems of inability to pump, labor and materials, etc., and achieve the effect of improving efficiency, reducing costs, and shortening the implementation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

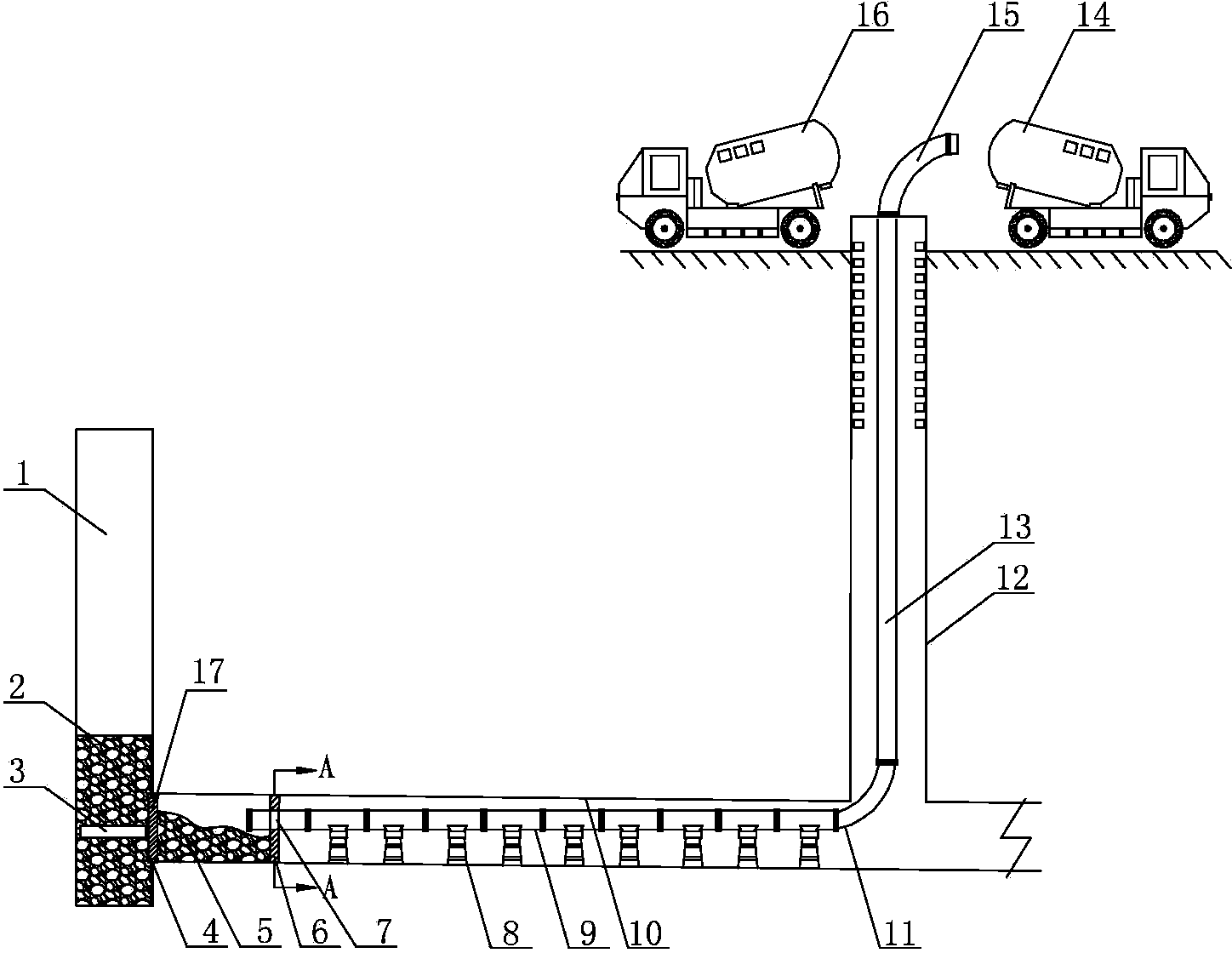

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

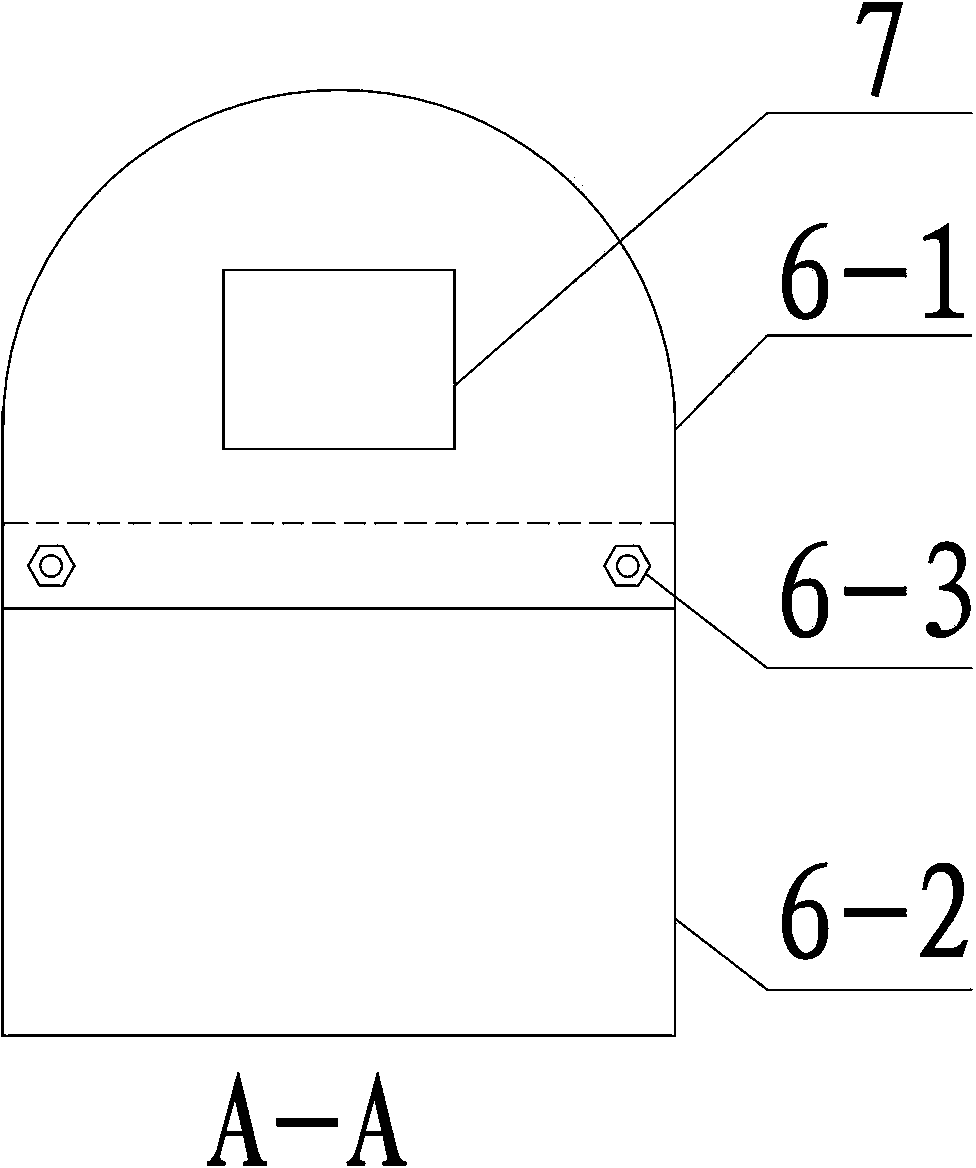

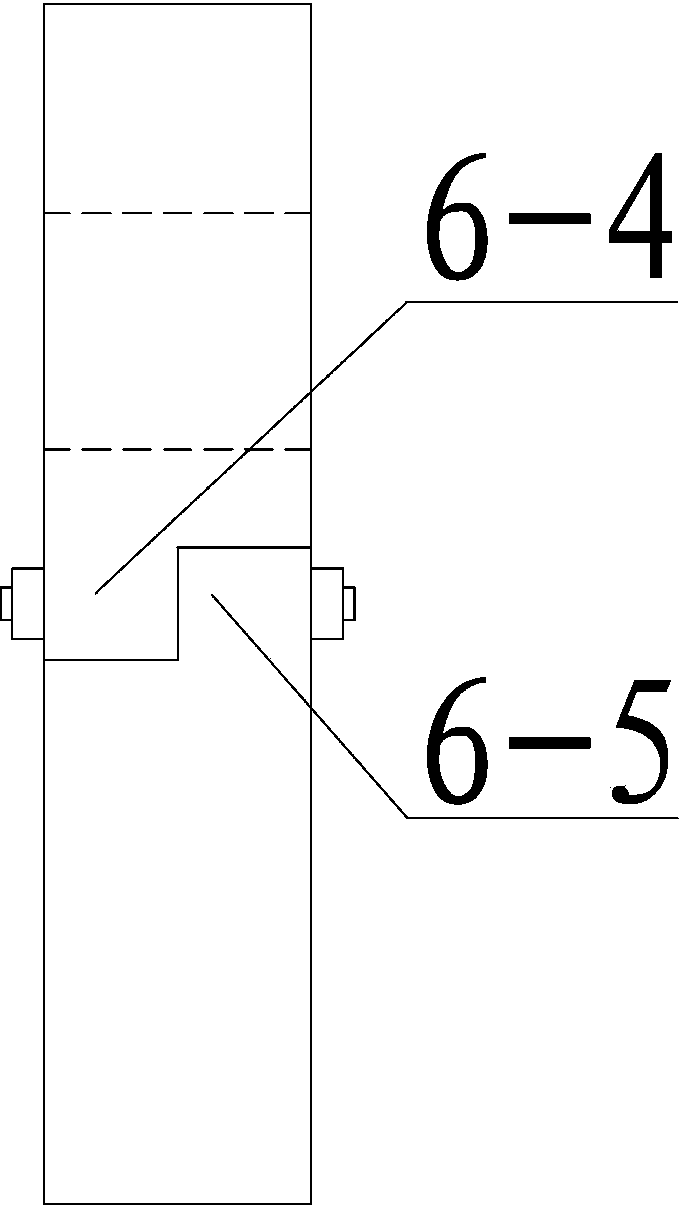

[0030] Such as Figure 1-Figure 3 As shown, the plugging system of the tailings pond overflow tower of the present invention includes a horizontal return pipe 10 connecting the old tower 1 and the new tower 12 of the tailings pond overflow tower, and a horizontal return pipe 10 is provided to connect the new tower. The horizontal blocking grouting pipeline 9 of tower 12 is provided with the longitudinal blocking pipeline 13 vertically connected with horizontal blocking grouting pipeline 9 in new tower 12, and its horizontal blocking grouting pipeline 9 is connected with the bottom of new and old tower respectively, It is characterized in that a plugging steel plate 4 and a lead screw 3 are provided at the connection between the old tower 1 and the horizontal return water pipe 10, and a return water pipe partition 6 is provided every 5-6m i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com