Concrete face rockfill dam leakage underwater blocking structure and method

A technology for concrete face and rockfill dam, which is applied in dams, barrages, water conservancy projects, etc., can solve the damage of faceplate and water-stop structure of face rockfill dam, the difficulty of dealing with the interface between new and old concrete, and the inability of face rockfill dam to empty the reservoir. and other problems to achieve the effect of reducing profit loss, ensuring the effect of silting, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and at the same time, the advantages of the present invention will become clearer and easier to understand.

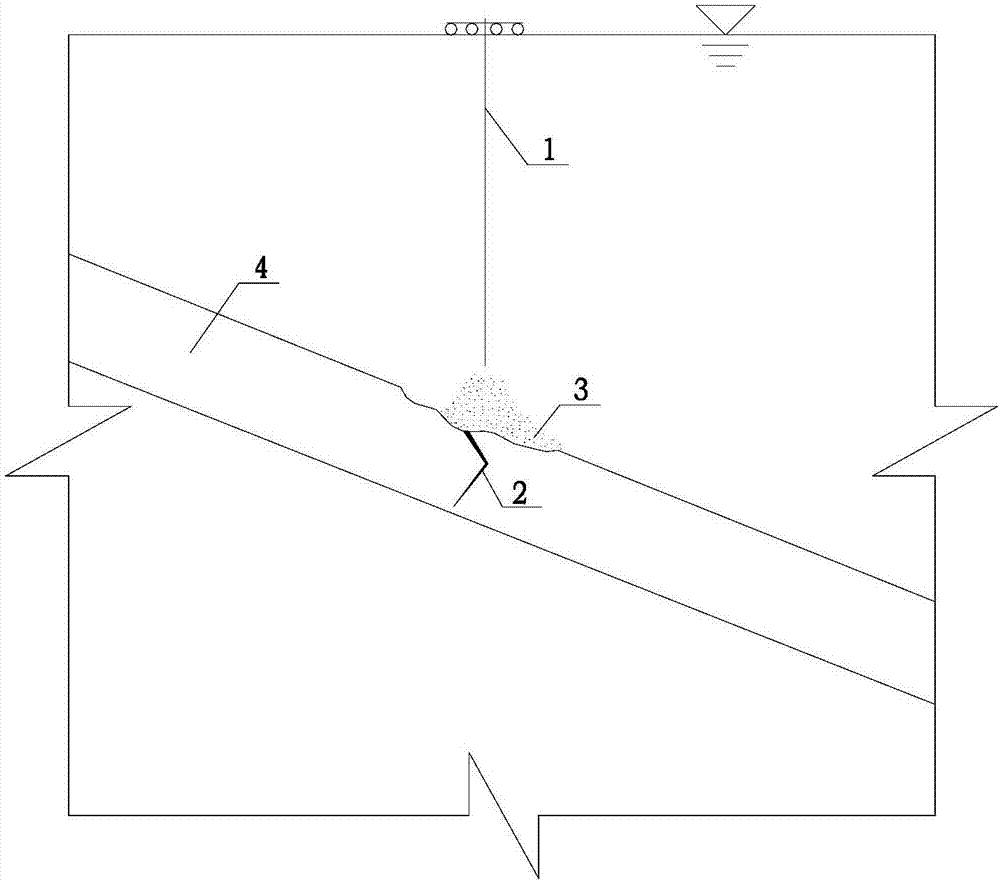

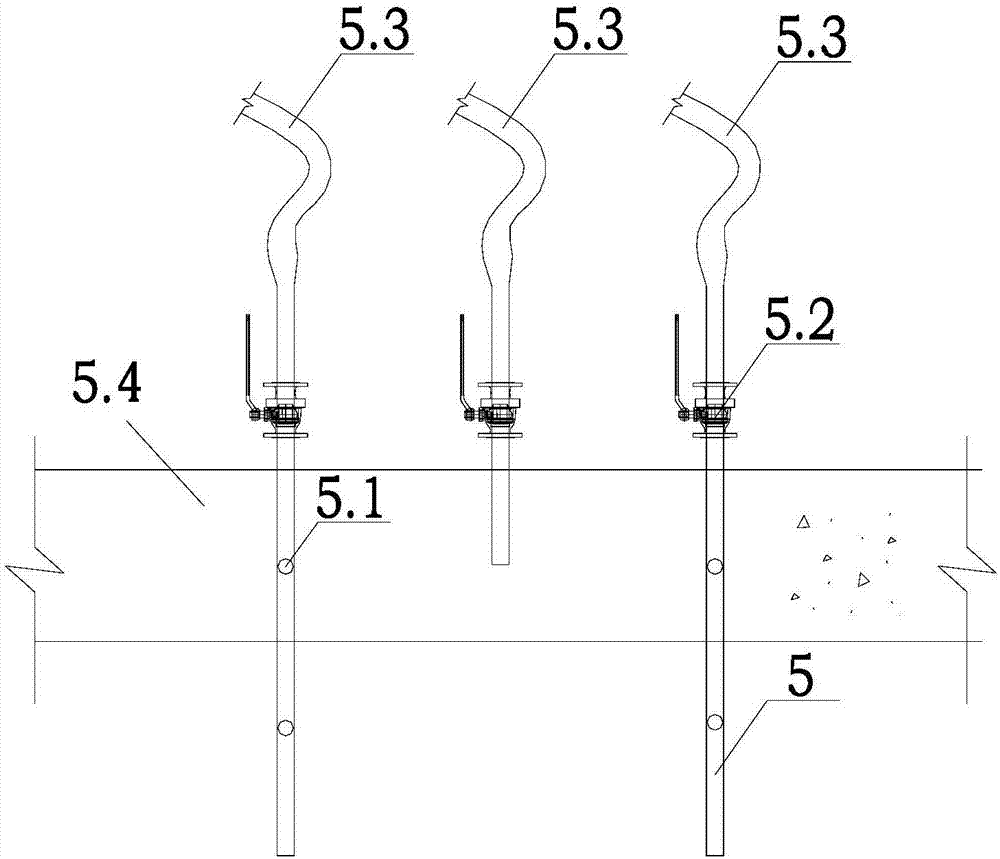

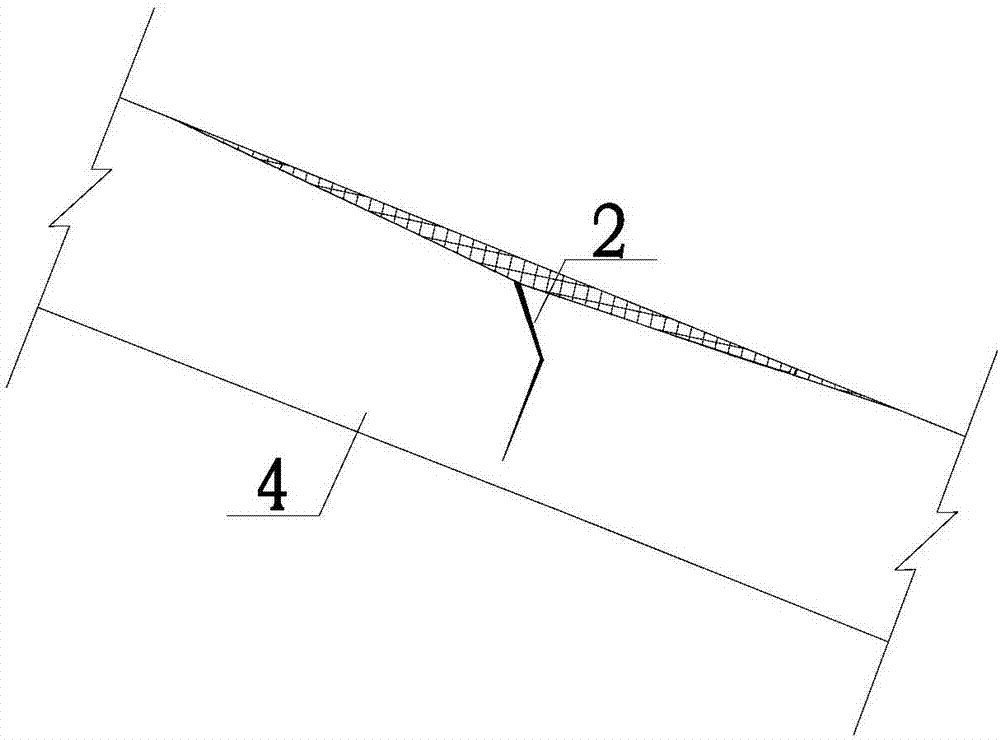

[0029] refer to Figure 1-5 Shown: a kind of concrete face rockfill dam seepage underwater plugging method of the present invention is characterized in that: it comprises the following steps;

[0030] ①. Underwater injection of silting material: The leakage flow rate at the staggered cracks or open joints below the water surface is relatively large, and the flow rate increases with the depth. The long-term effect of leakage will often take away the fine particles in the cushion material, causing the lower part of the panel 4 to be voided and cause collapse. It is very difficult to directly seal the cracks and cause the collapse of the voided panel; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com