Water plugging device for petroleum pipeline maintenance

A technology of oil pipelines and water stoppers, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve problems such as easy blockage of pipes, failure of water blocking, and unclean dismantling, so as to ensure the sealing effect , Guaranteed plugging performance and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

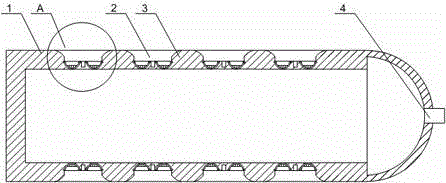

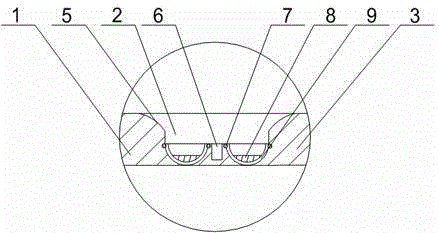

[0023] Such as figure 1 and figure 2 As shown, this embodiment includes an airbag body 1 and an exhaust pipe 4 provided at the end of the airbag body 1, and a plurality of grooves 2 are provided on the outer peripheral wall of the middle part of the airbag body 1, and in the grooves 2 Two elastic metal sheets 9 are arranged at intervals, and a reinforcing pad 8 is fixed on the inner bending part of the elastic metal sheet 9. When the airbag body 1 is inflated, the two elastic metal sheets 9 deform along the airbag body 1. expand radially outward.

[0024] When the drainage pipe is blocked, the present invention makes the following improvements for the protruding dirt on the inner wall of the pipe, replacing the existing cylindrical outer wall with an airbag body 1 with a plurality of annular grooves 2 in the middle , so that the dirt on the inner wall of the pipeline has a certain space when it contacts the airbag body 1, so as to prevent the dirt from being directly squeez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com