Novel membrane electrode structure of proton exchange membrane fuel cell and packaging method thereof

A technology of proton exchange membrane and fuel cell membrane, which is applied in the direction of fuel cells, battery electrodes, fuel cell components, etc., can solve problems such as low efficiency, high labor pressure, membrane leakage, etc., and achieve improved positioning and sealing effects , the effect of improving strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

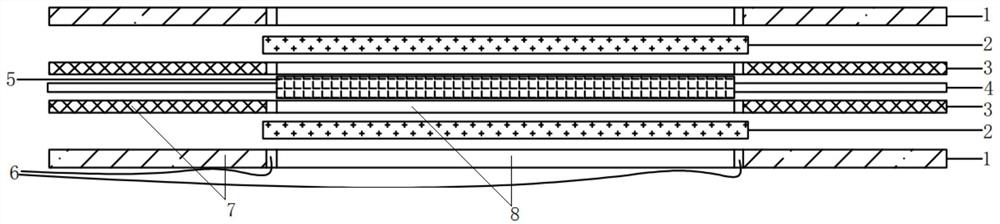

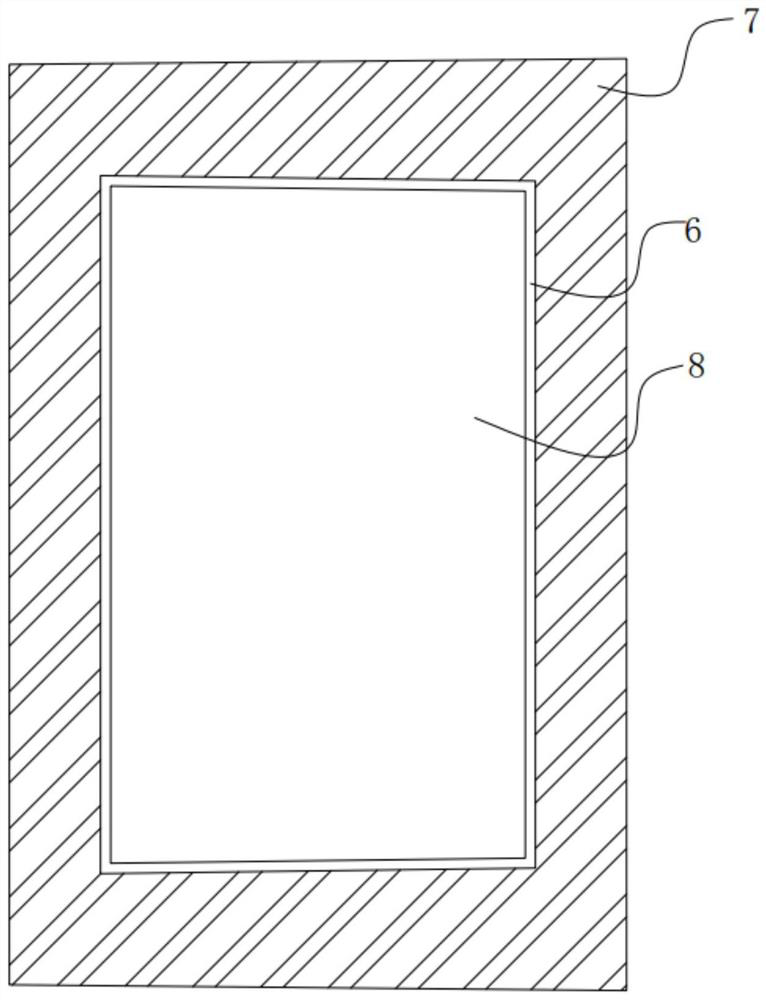

[0034] A novel membrane electrode structure for proton exchange membrane fuel cells, such as figure 1 As shown, it includes a proton exchange membrane 4, a catalyst layer 5 placed on both sides of the proton exchange membrane 4, two encapsulation frames 1 that cover the proton exchange membrane 4 and the catalyst layer 5, and the space between the encapsulation frame 1 and the catalyst layer 5 is A gas diffusion layer 2 is arranged between them, and at least one protective frame 3, a proton exchange membrane 4, a catalyst layer 5, a gas diffusion layer 2, an encapsulation frame 1 and a protective frame are arranged between the gas diffusion layer 2 and the catalyst layer 5. The center lines of 3 are overlapped, and the length and width are parallel to each other. The protective frame 3 and the package frame 1 are provided with through slots 8 with the same size and position.

[0035] A packaging process for a novel membrane electrode structure of a proton exchange membrane fue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com