Contact type sealing structure suitable for supercritical carbon dioxide compression unit

A technology of contact sealing and carbon dioxide, which is applied in the sealing of engines, sealing devices of piston pumps, mechanical equipment, etc., can solve the problems of national and enterprise losses and friction, reduce leakage, improve sealing effect, and avoid friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

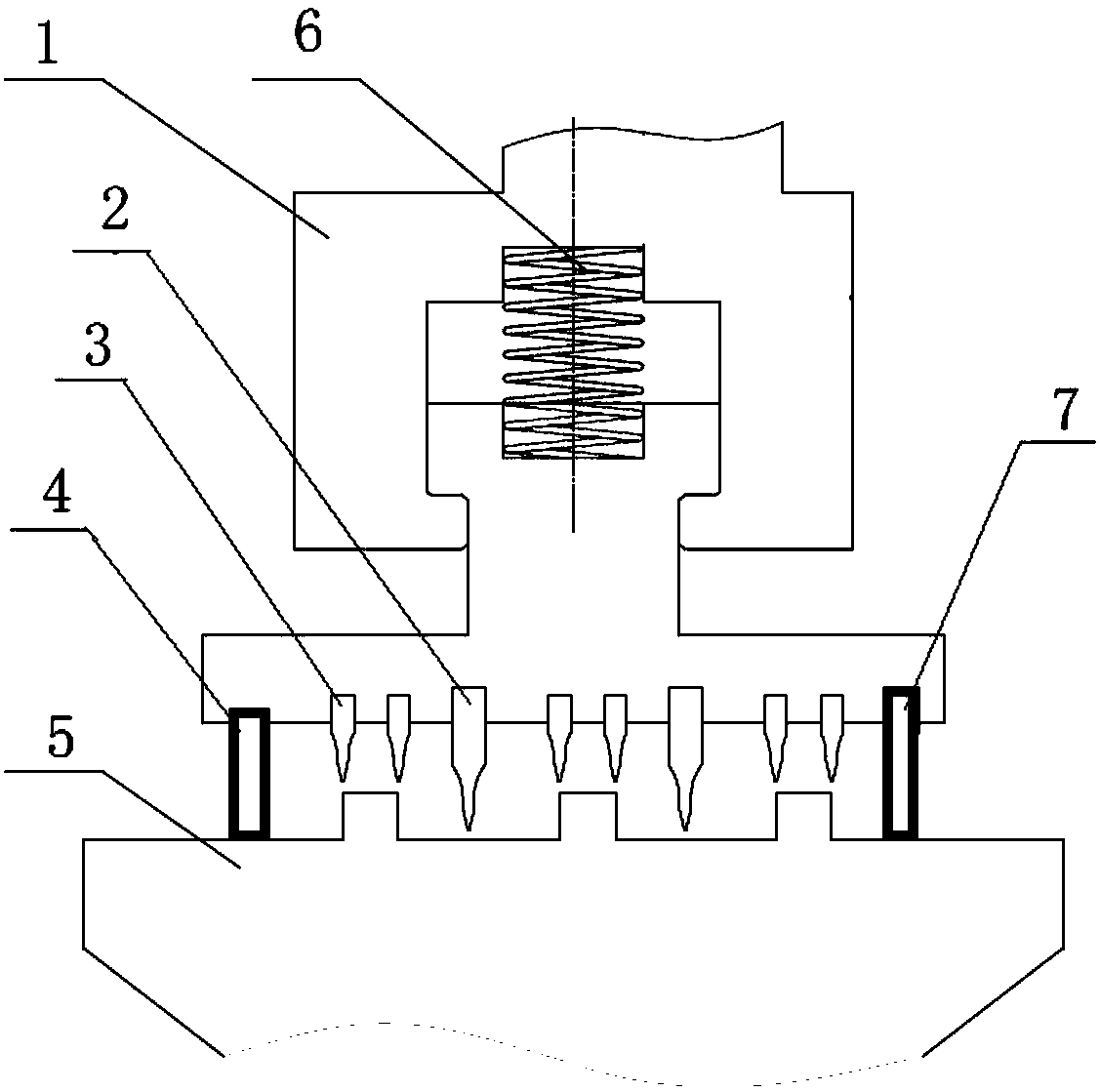

[0023] refer to figure 1 , the contact seal structure suitable for supercritical carbon dioxide compressor set according to the present invention includes a seal body 1, a first soft seal tooth 7, a second soft seal tooth 4, a shaft sleeve 5, several springs 6 and several seal teeth, the seal The body 1 is composed of an upper structure and a lower structure, wherein the bottom of the upper structure is provided with a card slot, the upper end of the lower structure is clamped in the card slot, one end of the spring 6 is connected to the bottom of the card slot, and the other end of the spring 6 One end is connected with the upper end of the lower structure, the upper end of the sealing tooth, the upper end of the first soft sealing tooth 7 and the upper end of the second soft sealing tooth 4 are all fixed on the lower end surface of the lower structure, and the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com