Automatic telescopic sealing device for compact shelves

A technology of automatic expansion and sealing device, which is applied to the sealing of the engine, engine components, cabinets for storing books, etc., can solve the problems of large separation gaps and poor sealing effect of the upper separation seams, and achieve the effect of ensuring uniform, reliable and effective.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

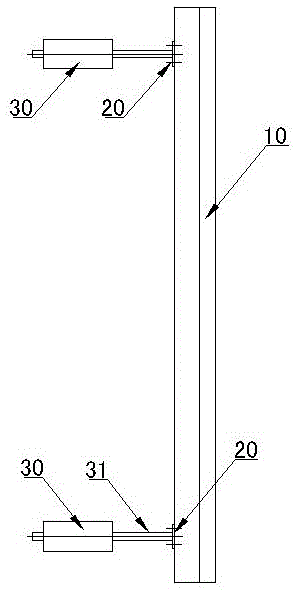

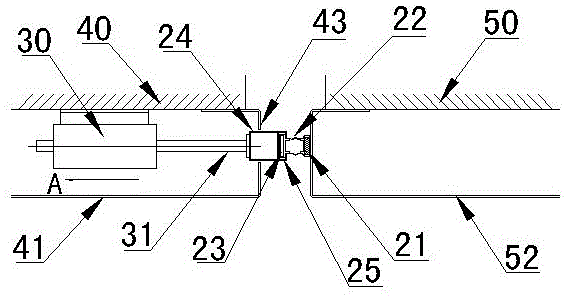

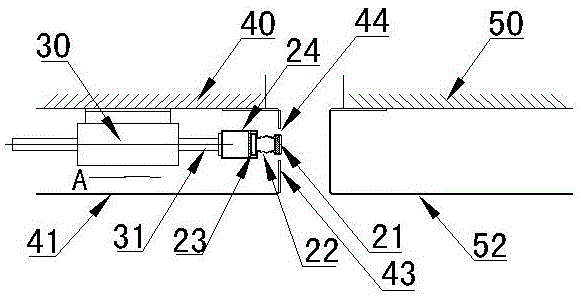

[0019] figure 1 , figure 2 , image 3 In the shown embodiment, an automatic telescopic sealing device for a compact shelf includes a compact shelf body 10, and two or more A linear motor 30 with a control circuit, each linear motor is distributed up and down in the side panel of the compact shelf body, the moving shaft 31 of each linear motor is connected with a sealing strip base 24, and the sealing strip base is embedded with Seal the sealing strip 20 of the side panels 42 of the adjacent two rows of compact racks; meanwhile, the side panel 43 of the compact shelf body is provided with a frame side panel opening 44 matched with the sealing strip base, and the sealing strip base 24 is placed on the linear motor. Driven by 30, the frame body side panel opening 44 can freely enter and exit, effectively driving the sealing strip 20 installed on the sealing strip base 24 to freely enter and exit the frame body side panel opening 44, so as to realize the adjustment and sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com