Vibration resistant type pipe cleaning valve

A technology of pigging and valve seat, applied in the field of pigging valves, can solve the problems such as easy vibration of pigging valves, and achieve the effects of preventing fluid from entering, working stably and preventing vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

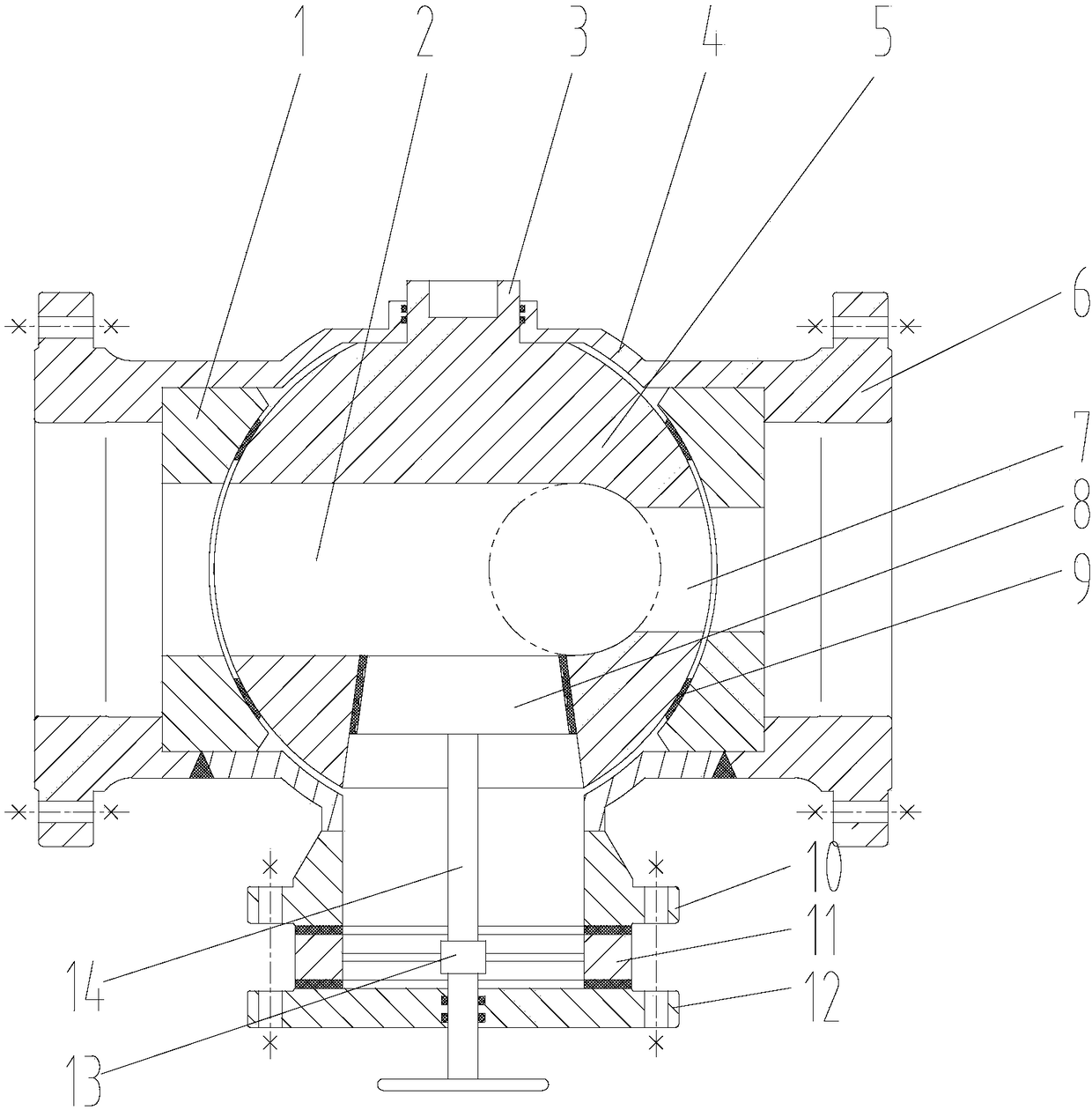

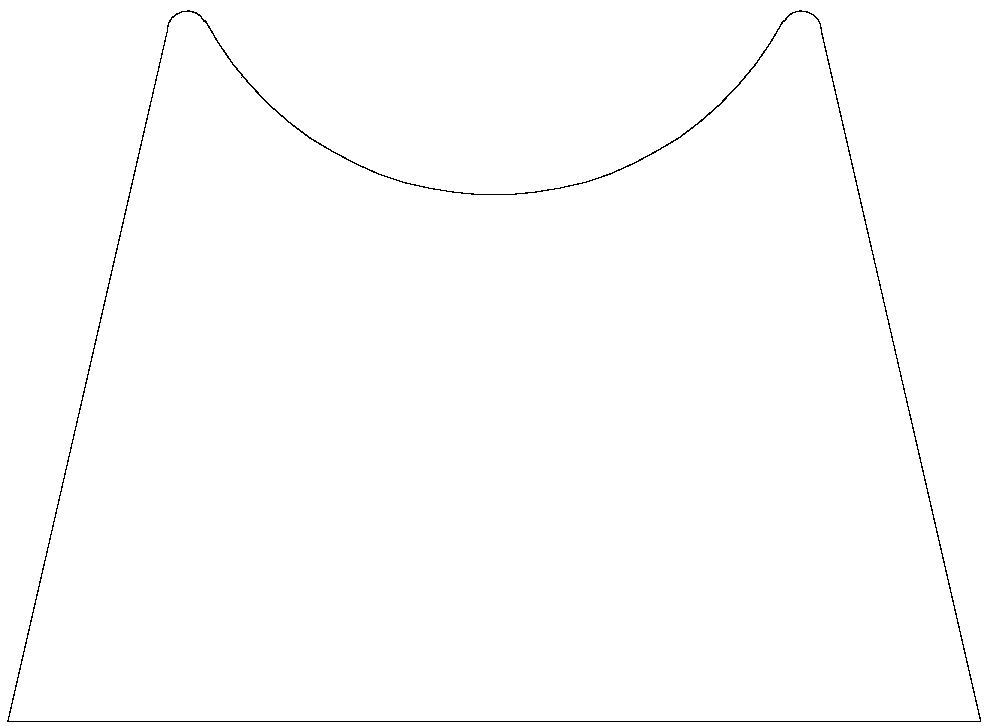

[0036] Such as figure 1 , figure 2 As shown, the present invention provides an anti-vibration type pigging valve, comprising a housing 4, and a sphere 5 horizontally rotated in the housing 4, and the sphere 5 is provided with a horizontally arranged inlet channel 2; the sphere 5 The main body corresponds to the inlet channel 2 and is coaxially provided with an outlet channel 7, and the diameter of the outlet channel 7 is smaller than the diameter of the inlet channel 2; the bottom of the sphere 5 is vertically provided with an access channel; the bottom of the housing 4 A discharge port is provided corresponding to the access passage, and a flange 6 assembly is provided corresponding to the discharge port; a plug post 8 adapted to it is provided in the entry and exit passage, the plug post 8 can seal the entry and exit passage, and the lower end of the plug post 8 is fixed A rod body 14 is connected, and the lower end of the rod body 14 protrudes downwards from the flange 6 ...

Embodiment 2

[0055] Such as figure 1 , figure 2 As shown, the present invention provides an anti-vibration type pigging valve, comprising a housing 4, and a sphere 5 horizontally rotated in the housing 4, and the sphere 5 is provided with a horizontally arranged inlet channel 2; the sphere 5 The main body corresponds to the inlet channel 2 and is coaxially provided with an outlet channel 7, and the diameter of the outlet channel 7 is smaller than the diameter of the inlet channel 2; the bottom of the sphere 5 is vertically provided with an access channel; the bottom of the housing 4 A discharge port is provided corresponding to the access passage, and a flange 6 assembly is provided corresponding to the discharge port; a plug post 8 adapted to it is provided in the entry and exit passage, the plug post 8 can seal the entry and exit passage, and the lower end of the plug post 8 is fixed A rod body 14 is connected, and the lower end of the rod body 14 protrudes downwards from the flange 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com