Agricultural and forestry waste picking and bundling device

A technology of agricultural and forestry waste and bundling devices, which is applied in packaging, agriculture, loaders, etc., can solve the problems of unfavorable mechanized feeding, high crushing cost, and low transportation efficiency, so as to achieve flexible transfer and operation, improve transportation efficiency, The effect of improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

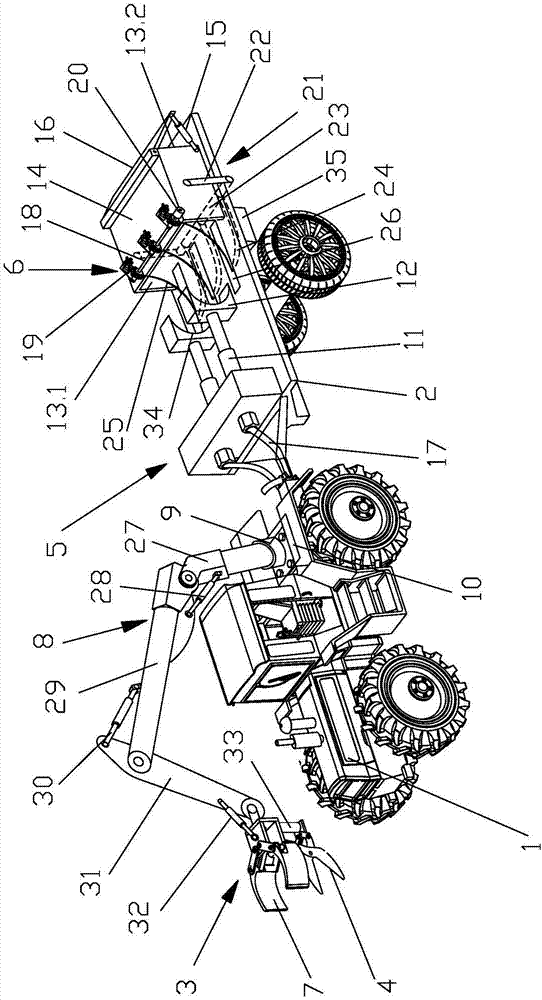

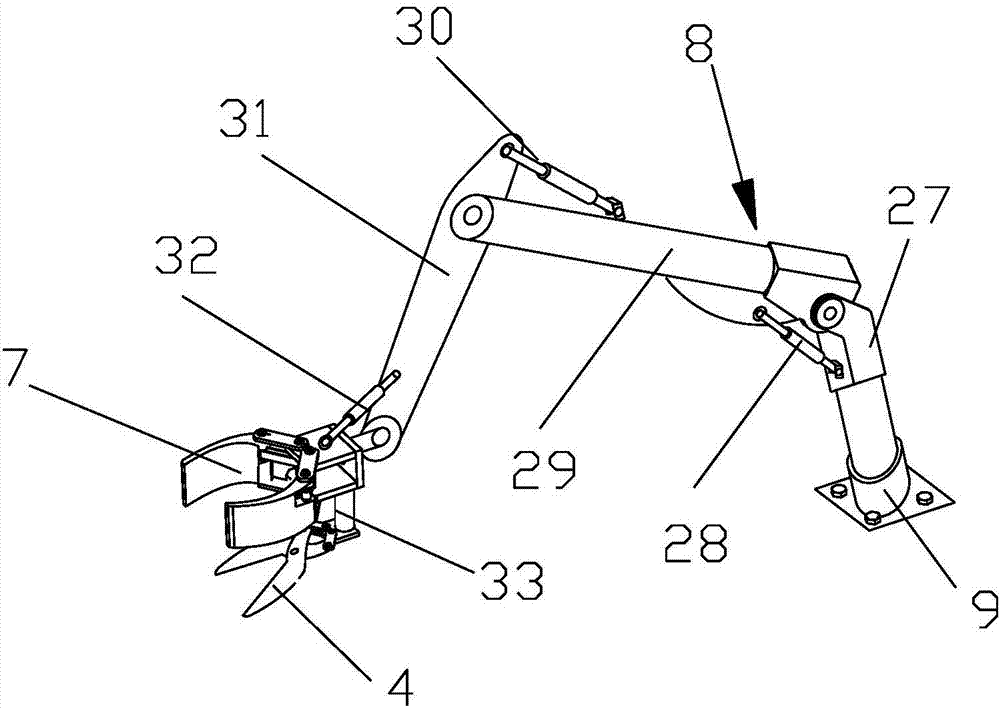

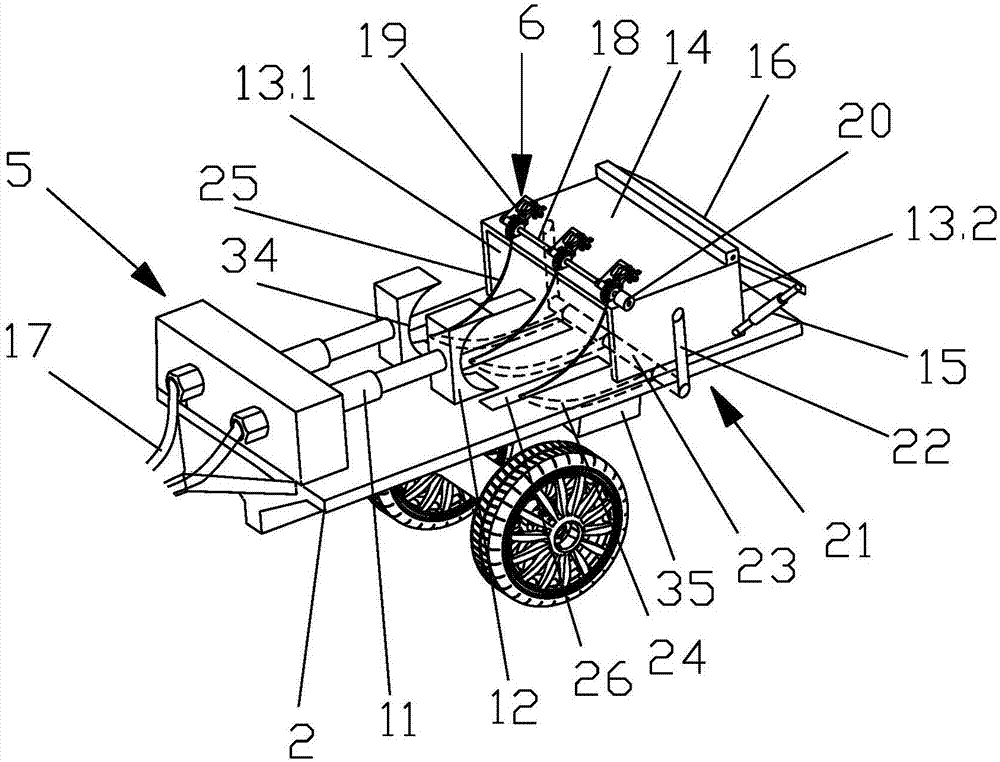

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] A picking and bundling device for agricultural and forestry waste shown in the figure is installed on a tractor 1 for picking and bundling agricultural and forestry waste. The rear of the tractor 1 is mounted with a frame 2, which includes a picking mechanism 3 and a harvesting mechanism 4 , hydraulic compression mechanism 5, and binding mechanism 6, also comprise the control box that is arranged on tractor 1 operating room, the control signal output end of control box is connected with pick-up mechanism 3, harvesting mechanism 4, hydraulic compression mechanism 5 and binding mechanism respectively 6 is connected to the control signal input terminal. The pick-up mechanism 3 includes a hydraulic gripper 7, a mechanical arm assembly 8 for driving the hydraulic gripper 7 to move up and down and to rotate circumferentially, and a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com