Flat-in and flat-out type garbage transfer station and operating method thereof

A garbage transfer vehicle and transfer station technology, which is applied in the direction of garbage transmission, garbage collection, transportation and packaging, etc., can solve the problems of small footprint, occupying more land area, and inability to reduce the occupied floor area and reduce the ground area. Area, the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

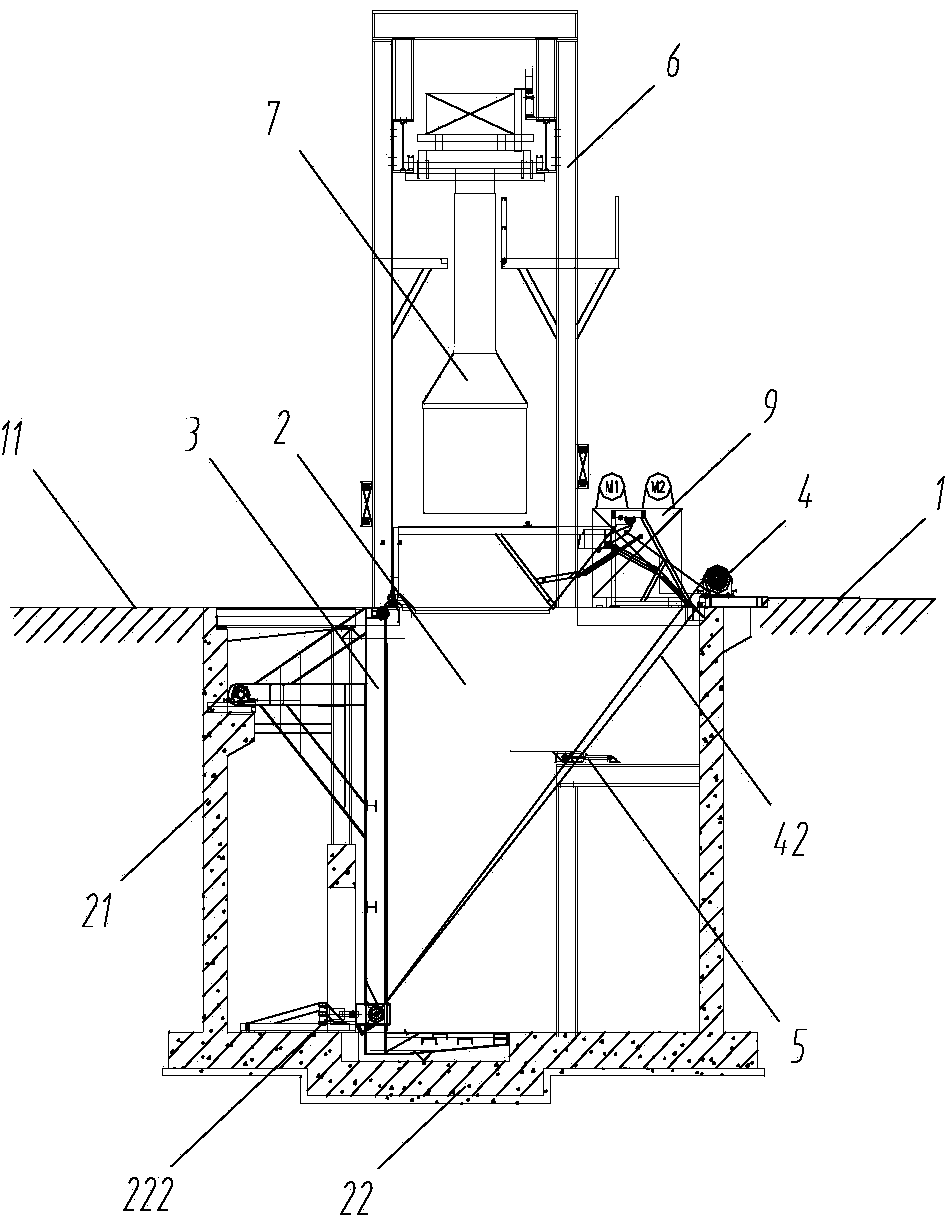

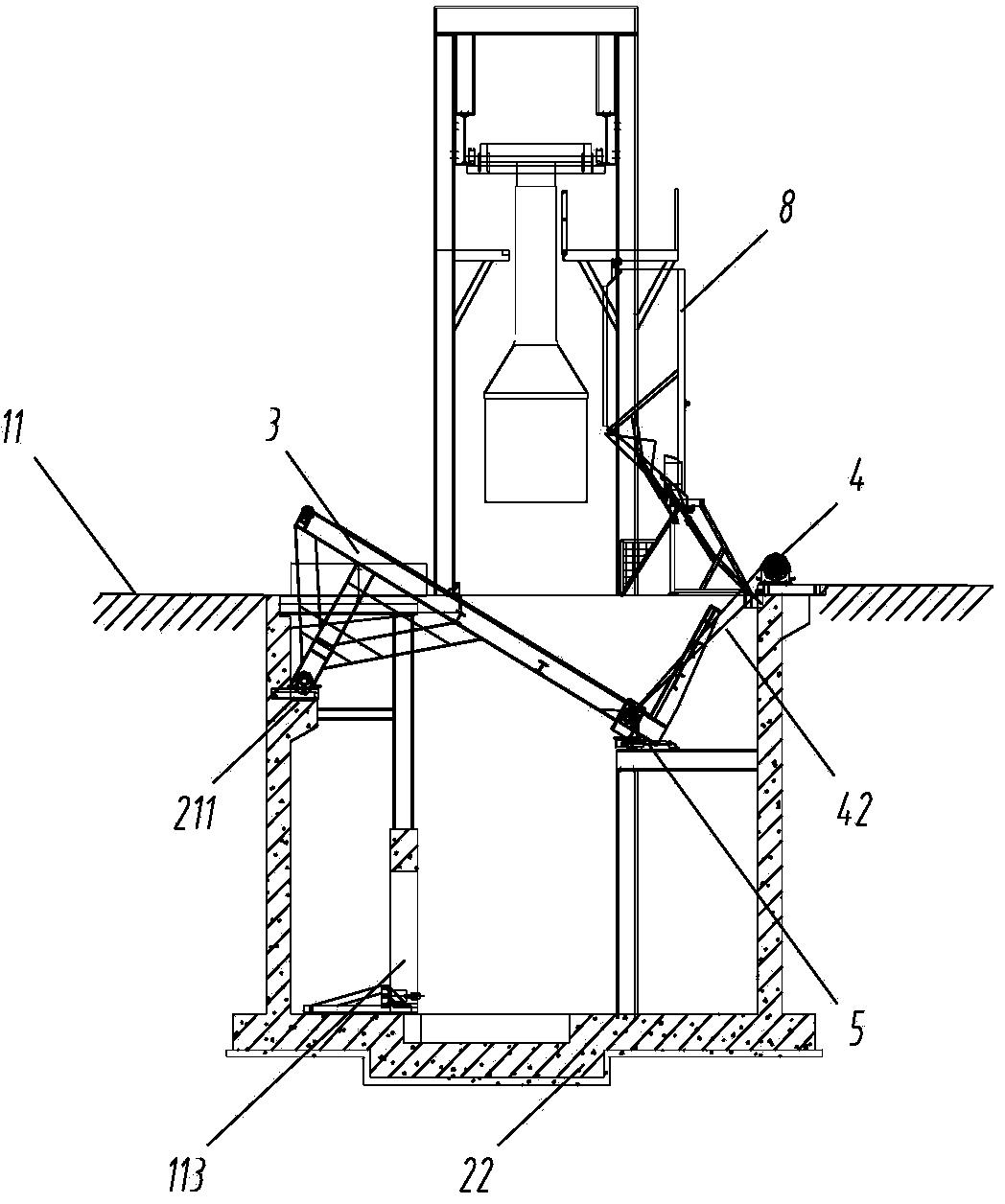

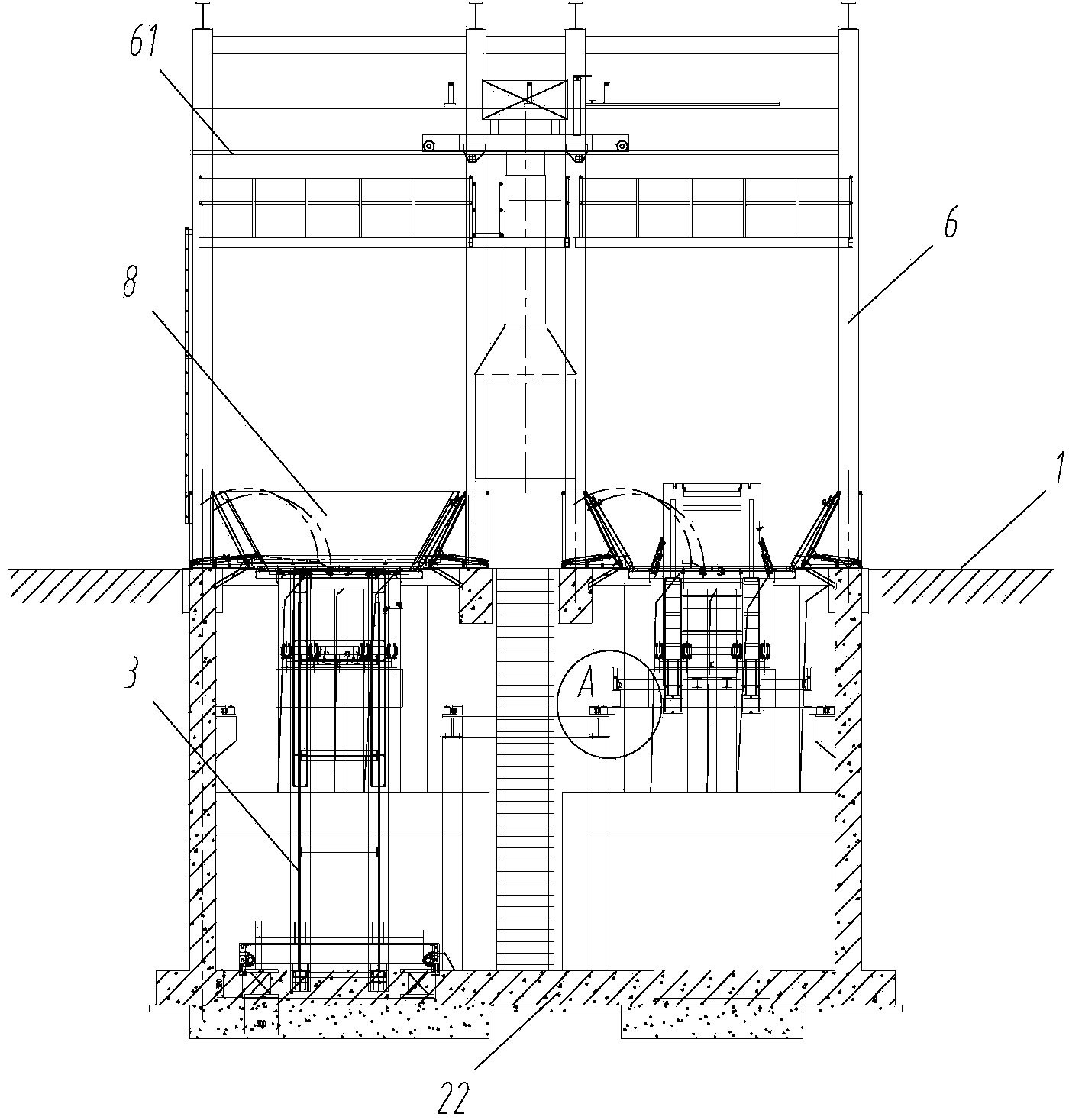

[0090] Such as figure 1 , 2 , shown in 3, this flat-in and flat-out type garbage transfer station mainly includes foundation pit 2, turning mechanism 3, hoisting mechanism 4, turning supporting mechanism 5, frame body 6, compactor 7, chute 8 etc. Usually, the datum level 1 is the land ground or the building ground, which is used to form the carrier of the entire garbage transfer station. According to the building code, the datum level 1 should be leveled, filled, hardened and other processes. Other devices supporting this garbage transfer station include a garbage transfer vehicle 100, a garbage collection vehicle 200, a vertical garbage container 300, and the like.

[0091] Such as Figure 5 , 6 , 7 and combine figure 1 , 2, 3. The foundation pit 2 is a space body excavated vertically downward from the building ground. It is a reinforced concrete structure with a length of 10100mm and a width of 7600mm. The height of the space is required to fully accommodate the axial l...

Embodiment 2

[0104] The design of the foundation pit 2 has multiple structures, and this embodiment is one of them. The pit wall on the left side is not vertically downward but designed to be inclined. The base 221 adopts an overall raised platform design, which is different from the previous embodiment. The difference also has hoisting mechanism 4 to adopt sprocket chain to promote, and chute 8 also adopts chain to promote.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com