Double-stamping-station plate material conveying device

A plate and station technology, applied in the field of double stamping station plate conveying devices, can solve the problems of low efficiency, easy to make mistakes, unfavorable organization of assembly line processing, and not easy to make mistakes, etc., and achieves high rotation precision, simple and practical structure, mobile precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

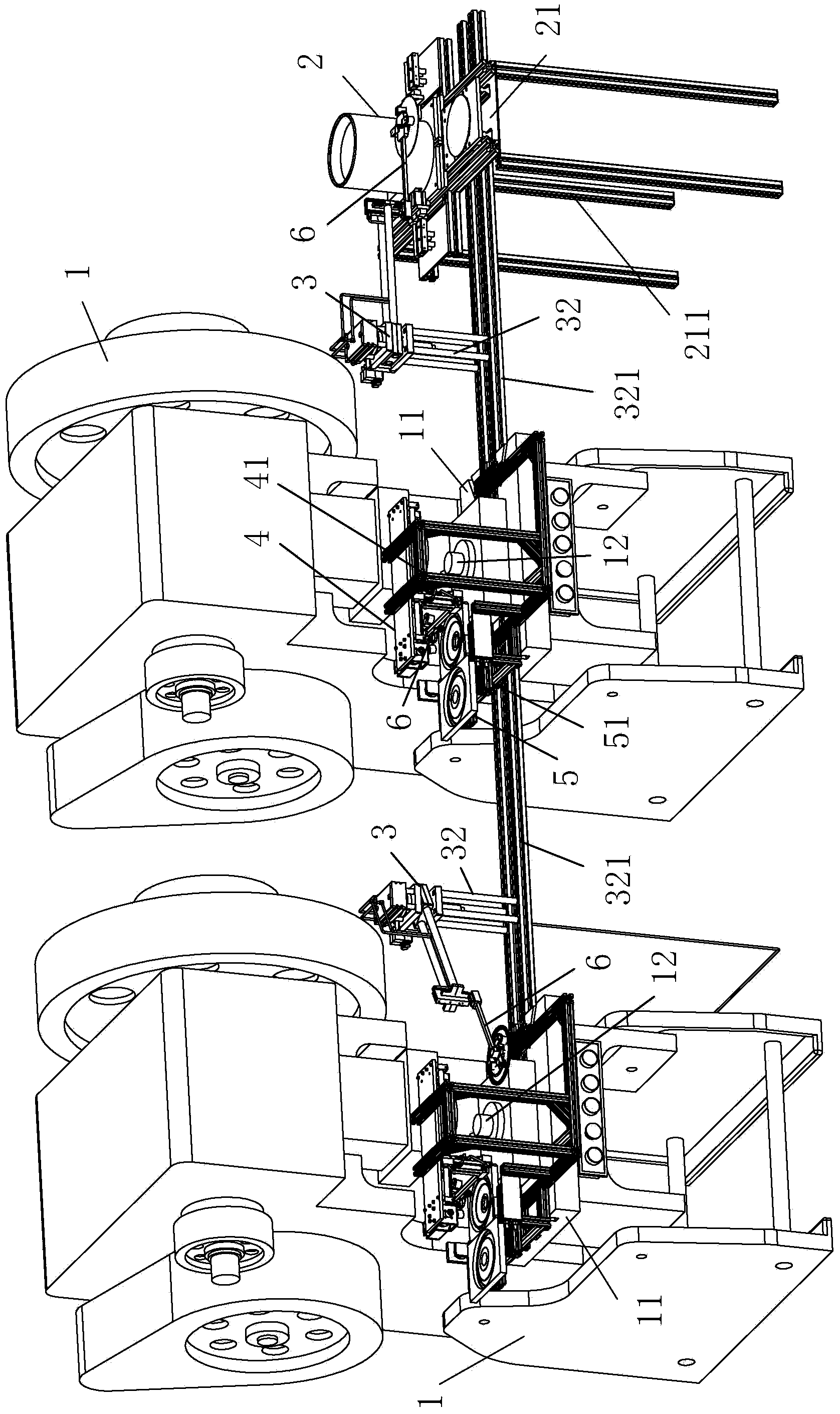

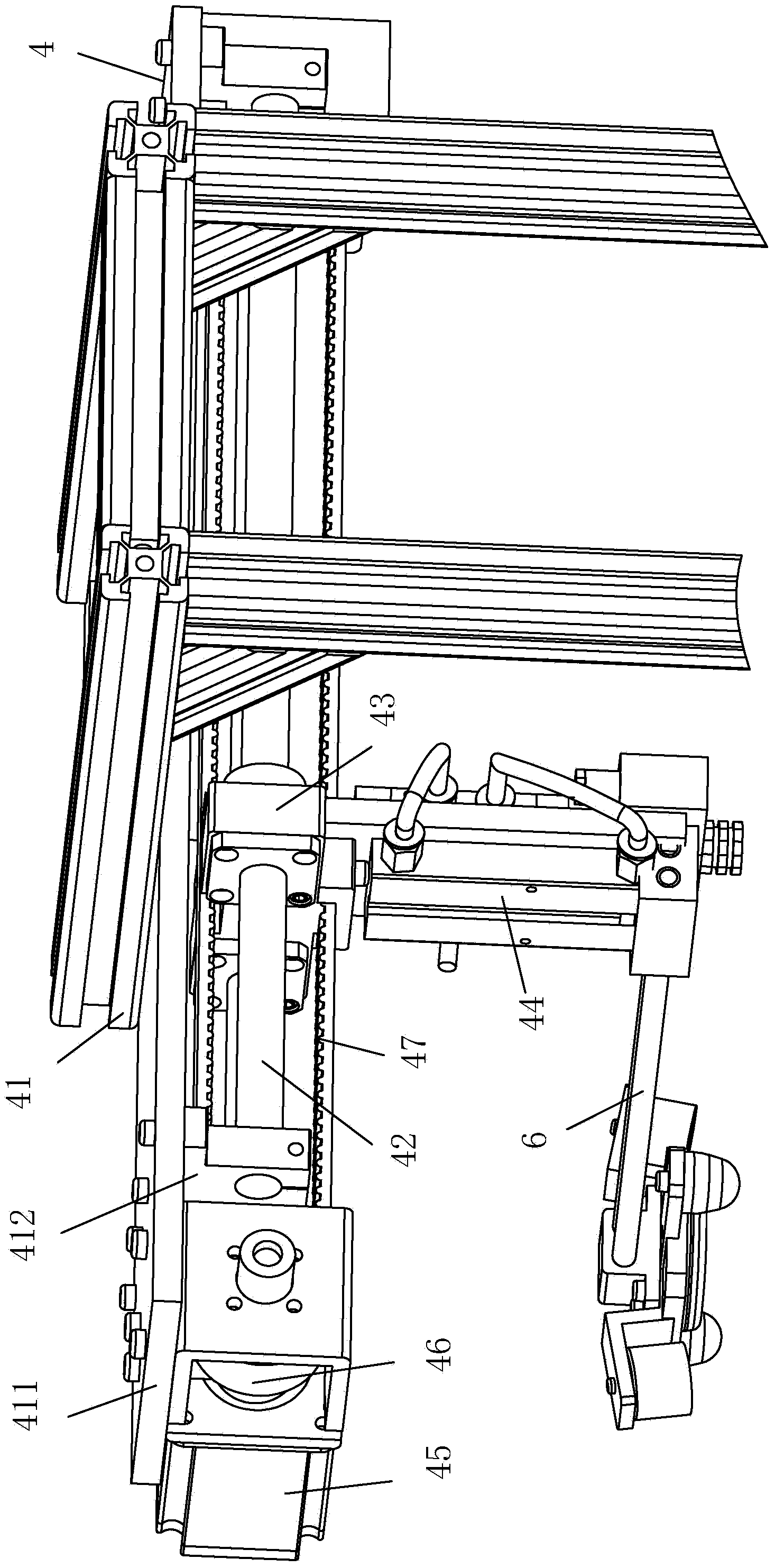

[0029] as attached figure 1Shown: a double stamping station plate feeding device, including two punches 1 with a lower die base 11 and a lower die 12, a plate distributing mechanism 2, two plate indexing mechanisms 3, and a lateral movement mechanism 4 and the plate turning mechanism 5; the plate distributing mechanism 2 is located on one side of a punch 1; a plate indexing mechanism 3 is located between the plate distributing mechanism 2 and the lower die 12 of a punch 1; The moving mechanism 4 is located at the front side of the lower die 12 of a punch press 1, and the plate turning mechanism 5 is located at the other side of the lower die 12 of a punch press 1; Between the lower dies 12 of another punch press 1.

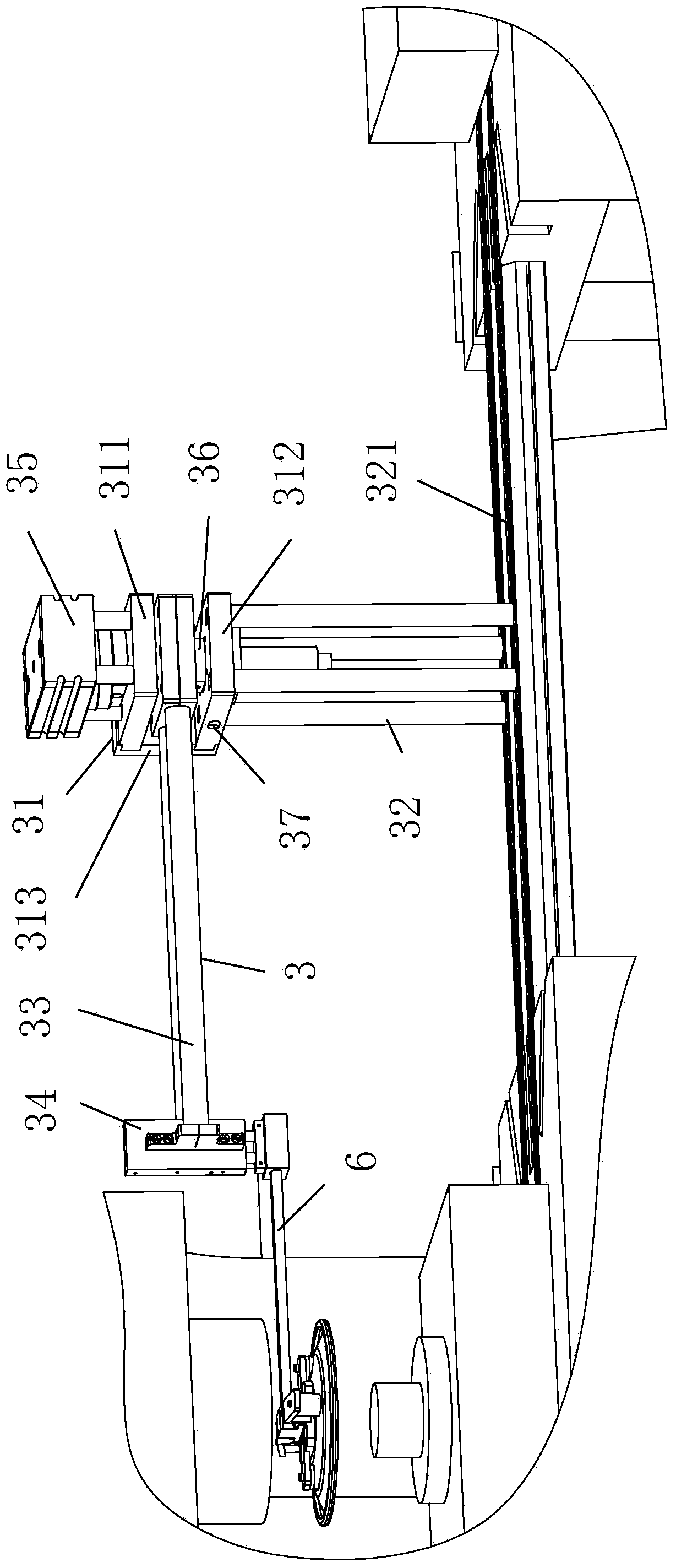

[0030] See attached figure 2 , the plate indexing mechanism 3 includes an upper end with a base frame 32, a swing arm 33 having a swivel seat 31 compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com