Rhomboid wheel-arranged cross-shaped axle 4WD (4 wheel drive) mechanism

A four-wheel drive, cross-bridge technology, applied to steering mechanisms, motor vehicles, control devices, etc., can solve the problems of not being able to meet the requirements of precise controllability, increasing technical difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

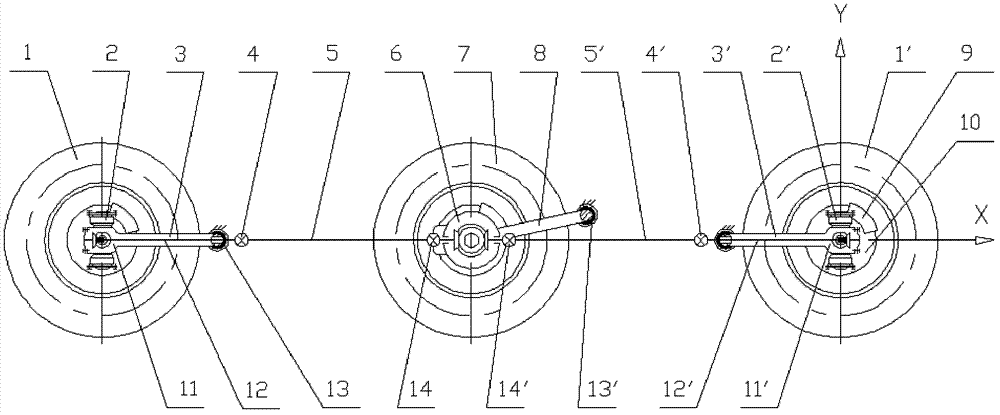

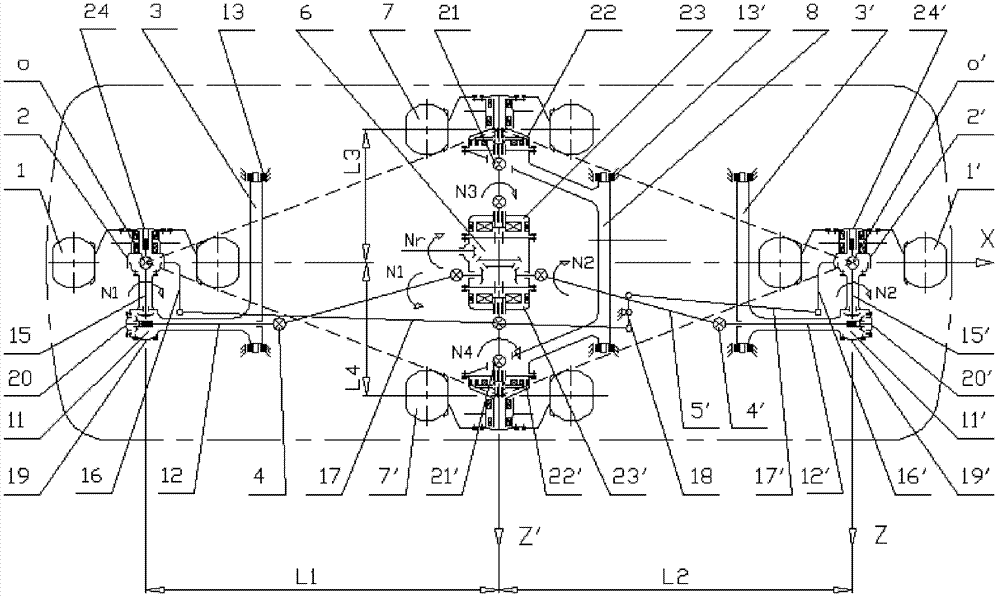

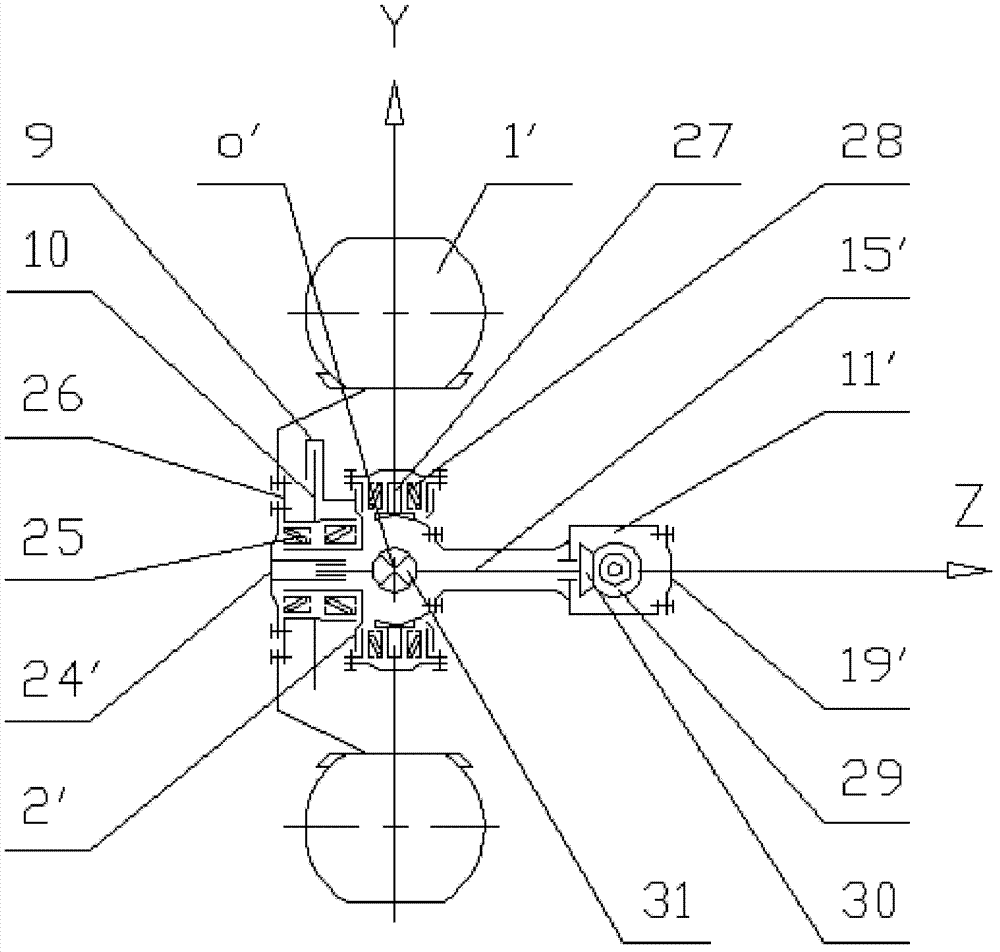

[0036] The present embodiment is a four-wheel drive mode in which the engine and the motor module are combined. The engine drives the left and right wheels 1, 1', and the motor drives the upper and lower wheels 7, 7'. figure 1 , 2 , 3, 4, 5 further explain the specific content and implementation process.

[0037] The four wheels 1, 1', 7, 7' are arranged on the 4 corners of the "◇" shape, wherein, the left wheel 1, the left steering kingpin assembly 2, the left " "Type Cantilever 3, Driver 6, Right" "Type cantilever 3', right steering kingpin assembly 2', right wheel 1' constitute the left and right direction steering drive axle, and the upper wheel 7, the upper electric clutch 22, the upper motor 23, the middle cantilever 8, the lower motor 23', the lower Electric clutch 22 ', lower wheel 7 ' constitute up and down direction driving axle, left and right direction steering driving axle and up and down direction driving axle form a cross type " ten " font structure driving ...

Embodiment approach 2

[0053] The present embodiment is the anti-skid driving mode of the left and right wheels 1, 1', which is a simplified form of Embodiment 1, or the anti-skid driving mode of the middle row of wheels. combined with figure 1 , 2 , 3, 4, and 6 illustrate the specific content and implementation process of this embodiment.

[0054] In the four-drive mode of the left, right, up, and down wheels 1, 1', 7, 7' in Embodiment 1, only two driving speeds N1, N2 are reserved, and two driving speeds N3, N4 are cancelled. Promptly remove the power and transmission parts of the upper and lower two wheels 7, 7 ', change the two wheels 7, 7 ' into passive wheels, and only utilize the rotating speed N1, N2 to drive the left and right two wheels 1, 1 '.

[0055] First remove the upper and lower motors 23, 23' from the driver 6 via screws I34 and I34', then remove the upper and lower spline half shafts 43, 43', universal joint V21 and universal joint V21', and upper and lower electric clutches 22 ...

Embodiment approach 3

[0058] This embodiment is the electric drive mode of the upper and lower wheels 7, 7', which is another simplified form of Embodiment 1, or the electric drive mode of the middle train wheel. combined with figure 1 , 2 , 3, 4, and 7 illustrate the specific content and implementation process of this embodiment.

[0059] In the four-drive mode of the left, right, up, and down wheels 1, 1', 7, 7' of Embodiment 1, only two driving speeds N3, N4 are reserved, and two driving speeds N1, N2 are canceled. Promptly remove the power and transmission parts of the left and right two wheels 1, 1 ', change the two wheels 1, 1 ' into passive wheels, and only utilize the rotating speed N3, N4 to drive the upper and lower two wheels 7, 7 '.

[0060] First remove the driver 6 via the screw I34 and the screw I34' respectively, then use the screw I34 to directly connect the upper and lower motors 23, 23' together and install them on the vehicle body or vehicle frame through the corresponding rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com