Deposition method of crystalline silicon battery back electrode, and obtained crystalline silicon battery

A crystalline silicon cell and deposition method technology, applied in the solar field, can solve problems such as increasing the fragmentation rate, and achieve the effects of reducing absorption, increasing current, and eliminating depressions and voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

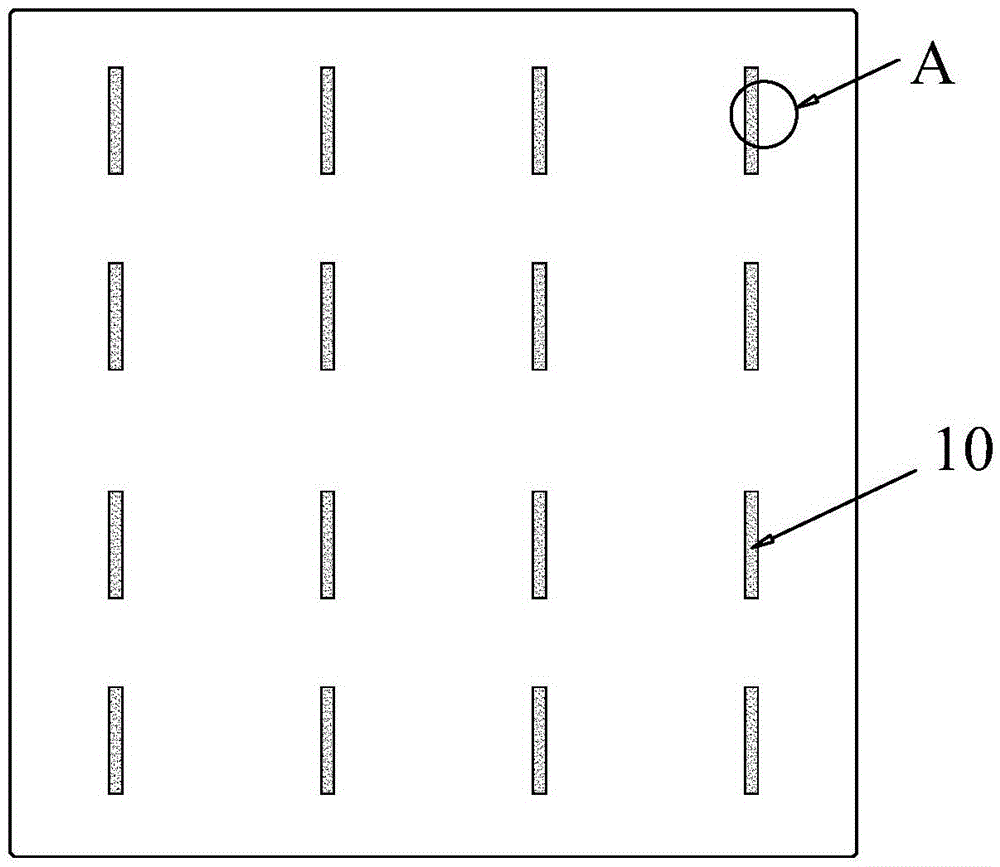

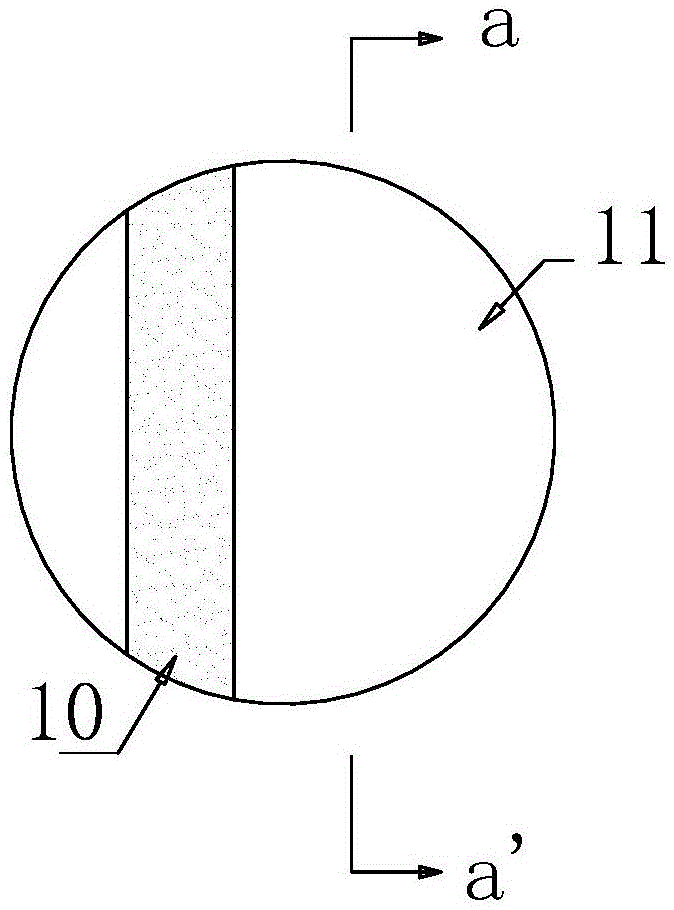

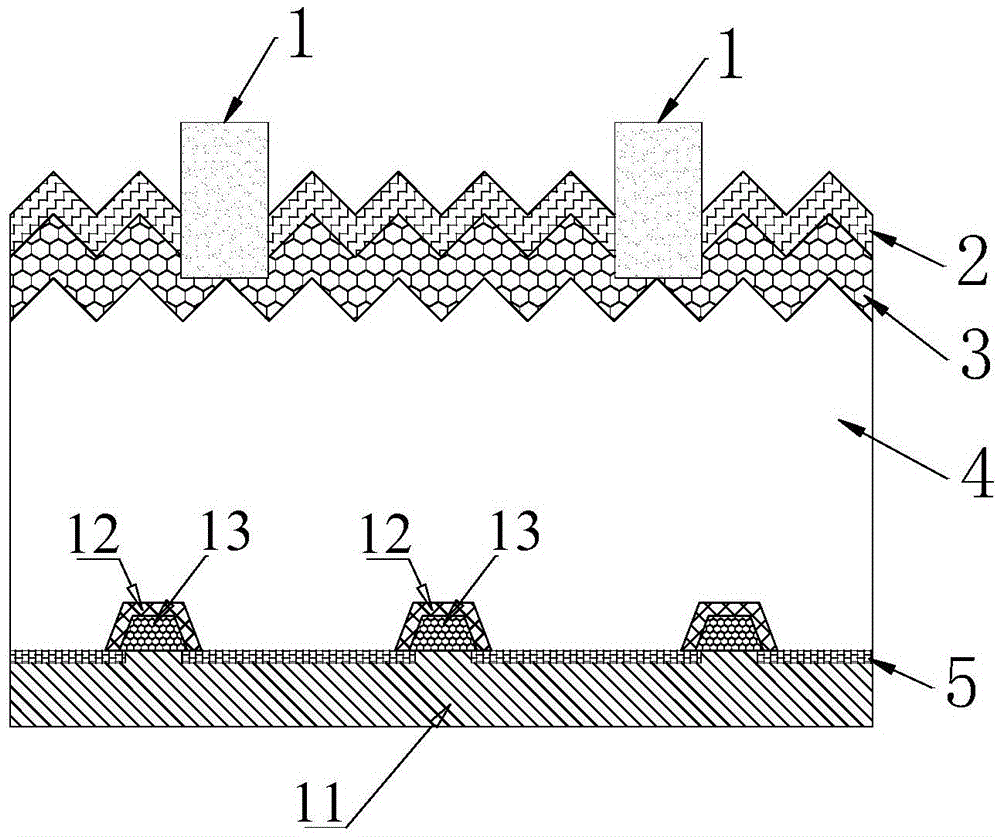

[0093] The specific embodiment one provides a PERC battery, the specific structure is as follows Figure 4~6 as shown ( Figure 4 The front view of the PERC battery structure schematic diagram provided for Embodiment 1, Figure 5 A partially enlarged front view of part A of the structural schematic diagram of the PERC battery provided for Embodiment 1, Image 6 Part A of the structural schematic diagram of the PERC battery provided for specific embodiment 1 along b-b' side view), includes the following structure:

[0094]The p-type silicon chip 4, the textured n+ doped layer 3 and the textured passivation film 2 arranged on the front side of the p-type silicon chip 4 in sequence, and the textured Ag electrode arranged on the textured passivation film 2 1;

[0095] There is a first passivation film 5 on the back side of the p-type silicon wafer 4, and there are a plurality of openings on the first passivation film 5; the inside of the openings is filled with electrodes 8 con...

Embodiment 1

[0097] Embodiment 1 provides the first preparation process of the PERC battery back structure obtained in Embodiment 1, which specifically includes the following steps:

[0098] (1) On the back side of the p-type silicon chip 4 with the partial opening of the passivation film distributed according to requirements, the back silver electrode 10 is deposited by screen printing;

[0099] (2) Printing and depositing an electrode 8 containing aluminum element at the partial opening, and the electrode 8 containing aluminum element is Ruxing Technology RX8201;

[0100] (3) screen printing silver paste on the back of the p-type silicon wafer 4 to obtain a barrier layer 7, the barrier layer 7 covers the electrode 8 containing aluminum;

[0101] (4) Continue to deposit a conductive electrode 9 on the back of the p-type silicon wafer 4, the conductive electrode 9 is Ruxing Technology 28D9, and the conductive electrode 9 covers the passivation of the barrier layer 7 and the back of the p-t...

Embodiment 2

[0105] Example 2 provides the second preparation process of the back structure of the PERC cell obtained in Embodiment 1, which specifically includes the following steps:

[0106] (1) Screen-print an electrode 8 at the partial opening on the back of the p-type silicon wafer 4 with the partial opening of the passivation film, and the electrode 8 is Ruxing Technology RX8256;

[0107] (2) Deposit a silver electrode on the back of the p-type silicon wafer 4, the deposition range is the predetermined position of the back silver electrode 10 to form the back silver electrode 10, and the local opening covers the electrode 8 containing aluminum element to form a barrier Layer 7, the barrier layer 7 is silver paste, and the deposition method is screen printing;

[0108] (4) Continue to deposit the conductive electrode 9 on the back of the p-type silicon wafer 4 , the conductive electrode 9 covers the barrier layer 7 and the passivation film area on the back of the p-type silicon wafer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com