Sulfur-carbon composite material coated with proton exchange membrane, its preparation method and application

A sulfur-carbon composite material, proton exchange membrane technology, applied in the field of electrochemistry, can solve the problems of reducing battery cycle stability and Coulomb efficiency, and achieve the effect of inhibiting the shuttle effect and preventing dissolution and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

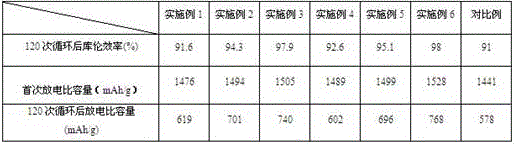

Embodiment 1

[0027] The preparation method of the sulfur-carbon composite material coated with proton exchange membrane comprises the following steps:

[0028] 1) Put sublimated sulfur and carbon black (super-P conductive carbon black) into the ball mill tank at a mass ratio of 7:3, the ball milling medium is raw material, ethanol and ball stone, and the mass ratio of raw material, ethanol and ball stone is 1:5 : 5, take out after ball milling 9h at the rotating speed of 300r / min, make carbon black mixed material after drying; Carbon black mixed material is put into the tubular heating furnace that is full of nitrogen, is warming up to with the speed of 5 ℃ / min 150°C, and kept at 150°C for 9 hours, then increased the temperature to 300°C at the same heating rate, continued to hold at 300°C for 2 hours, and cooled to room temperature to obtain a sulfur-carbon composite material.

[0029] 2) Take 20 mg of nafion film solution with a mass fraction of 5% purchased from DuPont in the United Sta...

Embodiment 2

[0033] The preparation method of the sulfur-carbon composite material coated with proton exchange membrane comprises the following steps:

[0034] 1) Put sublimated sulfur and carbon black (super-P conductive carbon black) into the ball mill tank at a mass ratio of 7:3, the ball milling medium is raw material, ethanol and ball stone, and the mass ratio of raw material, ethanol and ball stone is 1:5 : 5, take out after ball milling 9h at the rotating speed of 300r / min, make carbon black mixed material after drying; Carbon black mixed material is put into the tubular heating furnace that is full of nitrogen, is warming up to with the speed of 5 ℃ / min 150°C, and kept at 150°C for 9 hours, then increased the temperature to 300°C at the same heating rate, continued to hold at 300°C for 2 hours, and cooled to room temperature to obtain a sulfur-carbon composite material.

[0035] 2) Take 40 mg of nafion membrane solution with a mass fraction of 5% purchased from DuPont of the United...

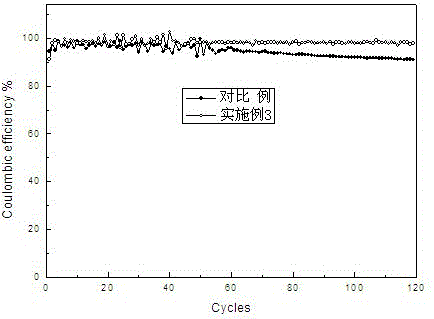

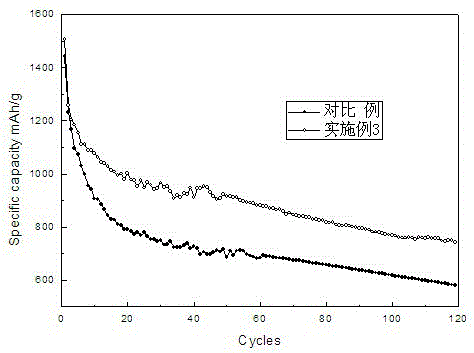

Embodiment 3

[0039] The preparation method of the sulfur-carbon composite material coated with proton exchange membrane comprises the following steps:

[0040] 1) Put sublimated sulfur and carbon black (super-P conductive carbon black) into the ball mill tank at a mass ratio of 7:3, the ball milling medium is raw material, ethanol and ball stone, and the mass ratio of raw material, ethanol and ball stone is 1:5 : 5, take out after ball milling 9h at the rotating speed of 300r / min, make carbon black mixed material after drying; Carbon black mixed material is put into the tubular heating furnace that is full of nitrogen, is warming up to with the speed of 5 ℃ / min 150°C, and kept at 150°C for 9 hours, then increased the temperature to 300°C at the same heating rate, continued to hold at 300°C for 2 hours, and cooled to room temperature to obtain a sulfur-carbon composite material.

[0041] 2) Take 100 mg of nafion membrane solution with a mass fraction of 5% purchased from DuPont in the Unite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com