Spherical nitrogen-doped carbon/titanium oxide double-shell coated titanium oxide/sulfur lithium-sulfur battery positive electrode material and preparation method thereof

A titanium oxide, nitrogen-doped carbon technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of ignoring the requirements of high coulomb efficiency, consumption, battery capacity attenuation, etc., to prevent concentration diffusion loss , the effect of improving Coulomb efficiency and preventing diffusion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

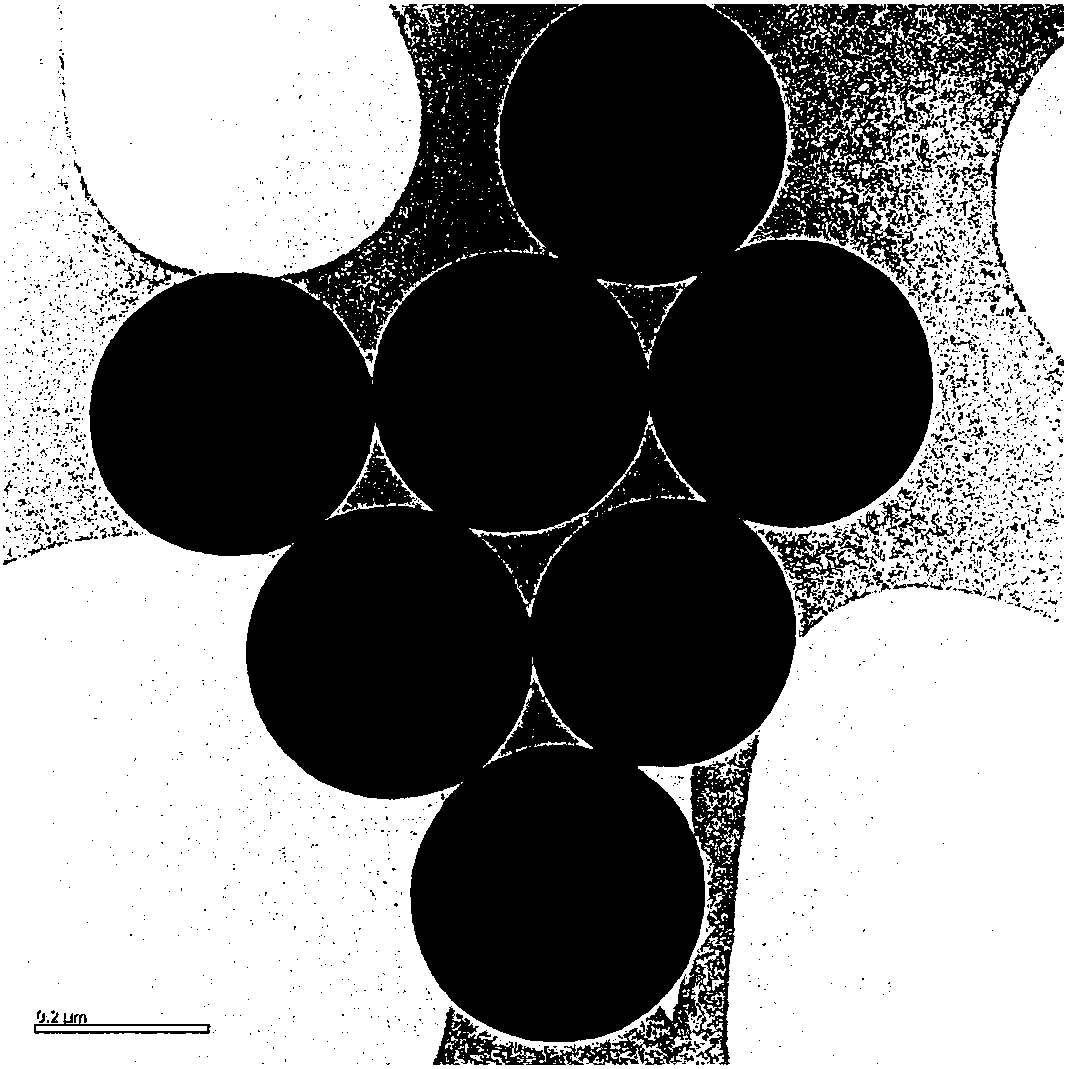

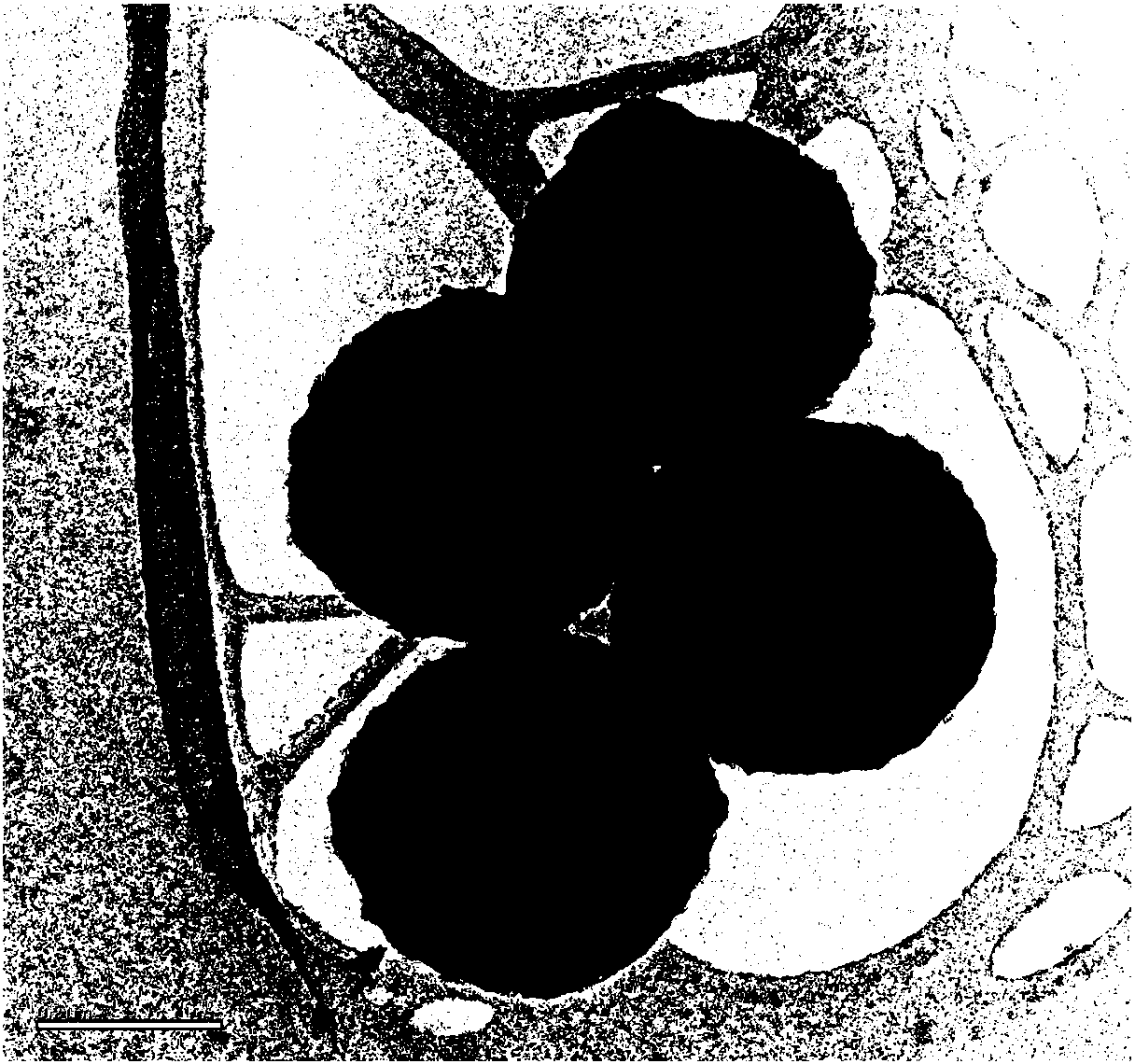

[0035] Step 1: Dispense 100 mg of SiO with a diameter of 280 nm 2 microspheres (see figure 1 ) was dispersed in 28 milliliters of organic solution (ethanol: acetonitrile is 3:1), and the concentration of 0.2 milliliters was added dropwise to 28% ammonia water and stirred for 60 minutes, then slowly added 4.4 milliliters of organic solution containing 10% TBOT (ethanol: Acetonitrile=3:1), stirred for 2 hours, and after washing with ethanol centrifugation, the obtained TiO 2 coated SiO 2 The microsphere product is put into a muffle furnace for calcination, the calcination temperature is 200 degrees, and the calcination time is 4 hours to obtain crystalline TiO with a diameter of 340 nanometers. 2 Coated SiO 2 microsphere product (see figure 2 ).

[0036] The second step: the crystalline TiO obtained in the first step 2 @SiO 2 The complex was dispersed into 100 ml of dopamine hydrochloride aqueous solution with a concentration of 1% and stirred for 4 hours, filtered and w...

Embodiment 2

[0041] Step 1: Dispense 100 mg of SiO with a diameter of 600 nm 2 The microspheres were dispersed in 28 ml of organic solution (ethanol: acetonitrile was 3:1), and 0.2 ml of 28% ammonia water was added dropwise and stirred for 60 minutes, then slowly added 4.4 ml of organic solution containing 15% TBOT (ethanol : acetonitrile=3:1), stirred for 2 hours, and after washing with ethanol centrifugation, the obtained TiO 2 coated SiO 2 The microsphere product is put into a muffle furnace for calcination, the calcination temperature is 400 degrees, and the calcination time is 4 hours to obtain crystalline TiO with a diameter of 680 nm. 2 Coated SiO 2 microsphere product.

[0042] The second step: basically the same as in Example 1, the obtained product was dispersed into 200 ml of dopamine hydrochloride aqueous solution with a concentration of 2% and stirred for 4 hours, then filtered, washed and dried with deionized water.

[0043] The third step: basically the same as in Exampl...

Embodiment 3

[0047] The first step: basically the same as in Example 1, add 4.4 ml of organic solution (ethanol: acetonitrile=3:1) containing 20% TBOT to obtain a crystalline TiO with a diameter of 360 nanometers 2 Coated SiO 2 microsphere product.

[0048] The second step: basically the same as in Example 1, the obtained product was dispersed into 200 ml of dopamine hydrochloride aqueous solution with a concentration of 2% and stirred for 6 hours, then filtered, washed and dried with deionized water.

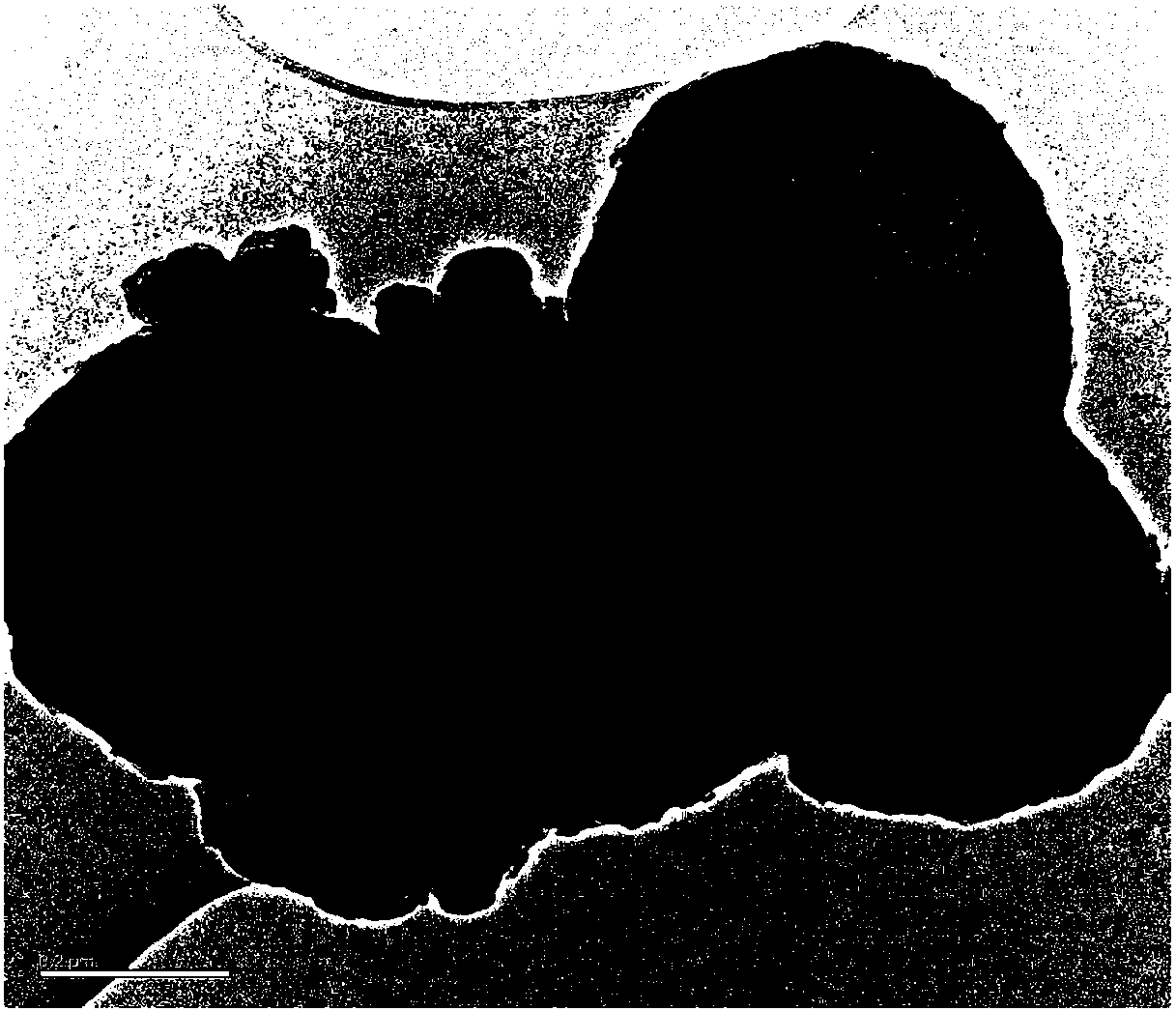

[0049] The third step: basically the same as in Example 1, the composite material is put into a tube furnace with a nitrogen-hydrogen mixture (nitrogen: hydrogen is 3:1), and the flow rate of the mixture is 60 ml / min. The temperature was raised to 1050 degrees at a rate of 5 degrees per minute, and the temperature was kept constant for 6 hours to obtain a spherical structure of NC / Ti with a diameter of 410 nanometers 4 o 7 Double shell coated Ti 4 o 7 Composite materials of nanoparti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com