Cement furnace coal-fired flue gas powerful denitration, sulfur fixation and purification system and process

A technology of coal-fired flue gas and purification system, applied in the field of environmental pollution control, can solve the problems of difficult environmental control requirements of cement furnaces, complex processes and high investment, and achieve the effects of less equipment, simple process and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention is further elaborated.

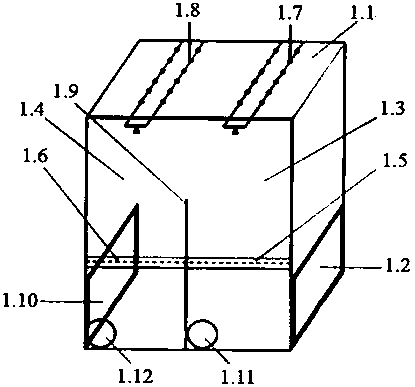

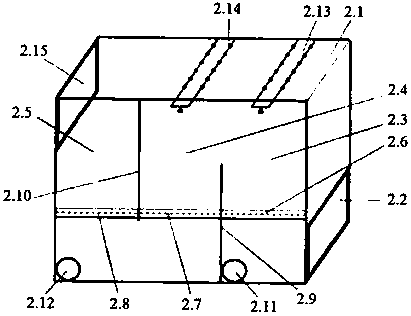

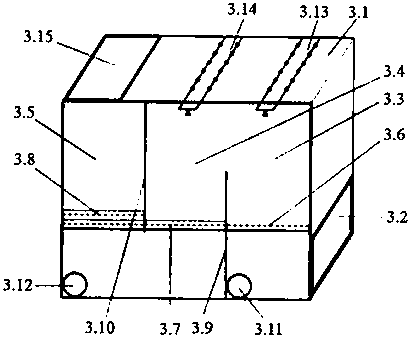

[0035] Such as figure 1 shown (and see Figure 2-Figure 4 ), the cement kiln coal-fired flue gas powerful denitrification and sulfur fixation purification system of the present invention includes a cooling and dust removal device 1, a catalytic denitrification device 2 and a harmful substance absorption and removal device 3. The coal-burning flue gas is passed into the smoke inlet 1.2 of the cooling and dust removal device, and the smoke outlet 1.10 of the cooling and dust removal device is connected to the smoke inlet 2.2 of the catalytic denitrification device, and the smoke outlet 2.15 of the catalytic denitrification device is connected to the smoke inlet 3.2 of the harmful substance absorption and removal device , the purified flue gas is discharged from the smoke outlet 3.15 of the harmful substance absorption and removal device. The purification system also includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com