High-temperature high-pressure high-shear rate lubricating oil rheometer

A high-temperature, high-pressure, high-shear technology, applied in the field of testing, can solve the problems of inaccurate calculation results, errors, deviations, etc., to ensure accuracy, improve service life, and reduce torque errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

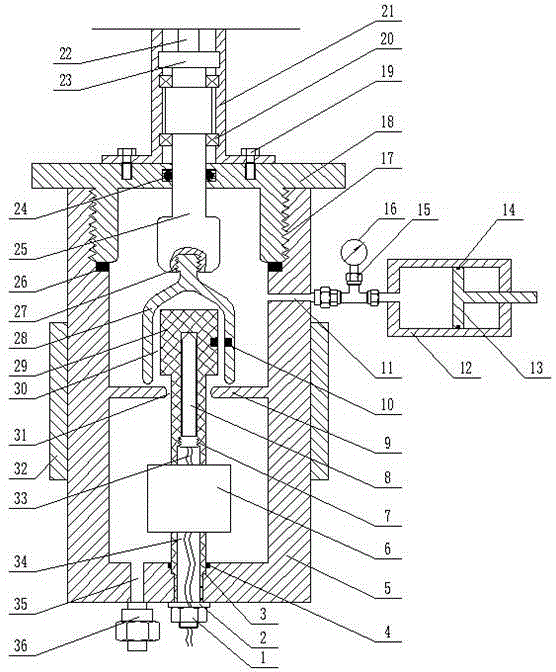

[0022] Such as figure 1 As shown, the lower end of the motor frame 21 of the present invention is fixed on the top of the cylinder head 18 by screws 19, and the motor output shaft 22, coupling 23, thrust bearing 20 and rotating shaft 25 are installed from top to bottom in the motor frame 21, and the bottom of the rotating shaft 25 A threaded hole 27 is processed, and the threaded hole 27 is connected with the external thread on the upper part of the outer cylinder 28. The larger diameter part of the upper part of the inner cylinder 29 is covered by the outer cylinder 28, and there is a shear gap between the outer cylinder 28 and the inner cylinder 29 30. A micro-gap measuring device 10 is installed on the inner wall of the outer cylinder 28 and the outer wall of the inner cylinder 29. The inner cylinder 29 has an inner cylinder hole 34, and the inner cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com