Intelligent constant-flow individual air dust sampler and constant-flow control method

An air dust and sampler technology, applied in the direction of using electrical device flow control, instruments, sampling devices, etc., can solve the problem that feedback control, automatic compensation and correction cannot be realized, rotameter cannot provide electrical signal output, and cannot form a closed-loop control system. and other problems, to achieve the effect of small resistance, convenient production and convenient wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

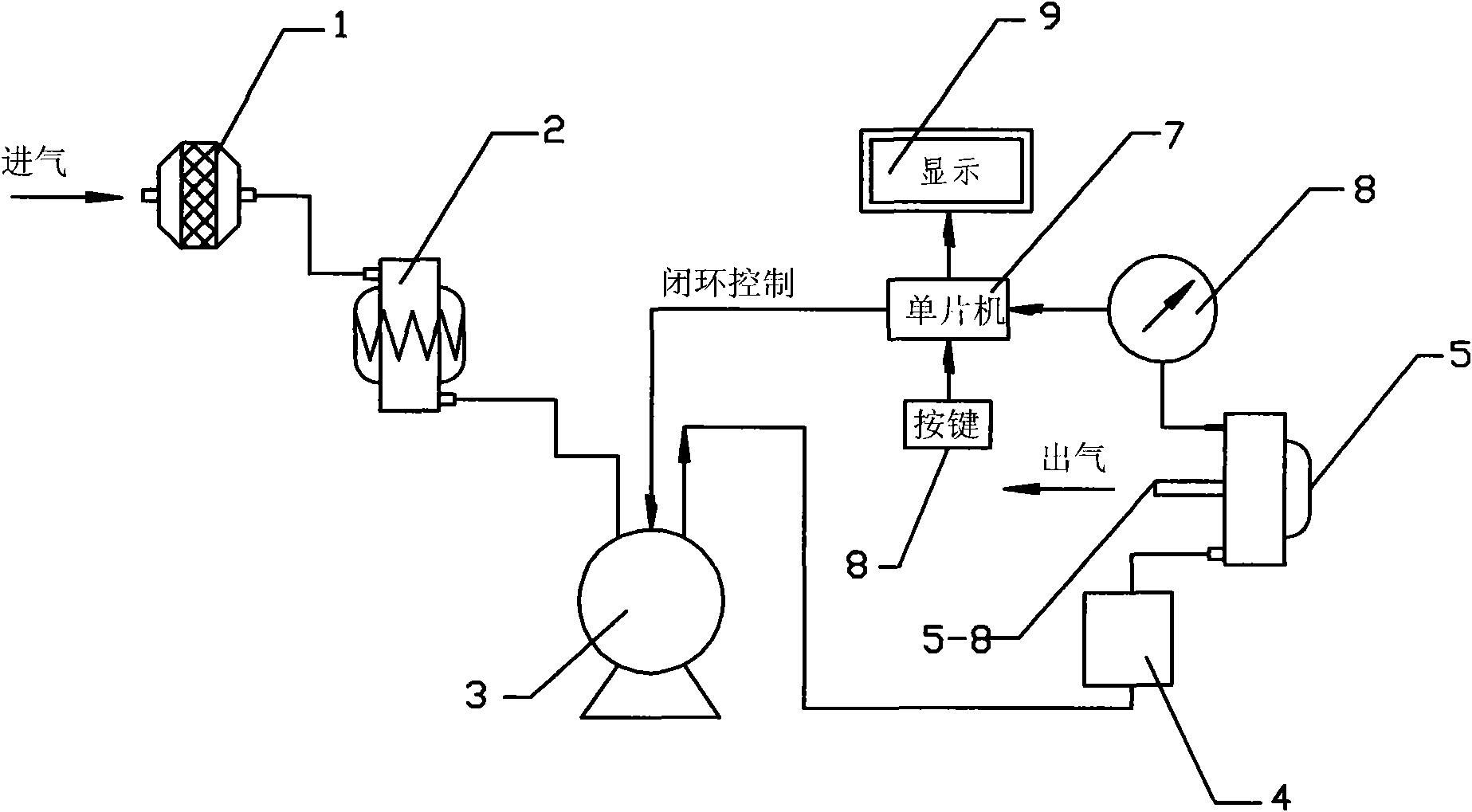

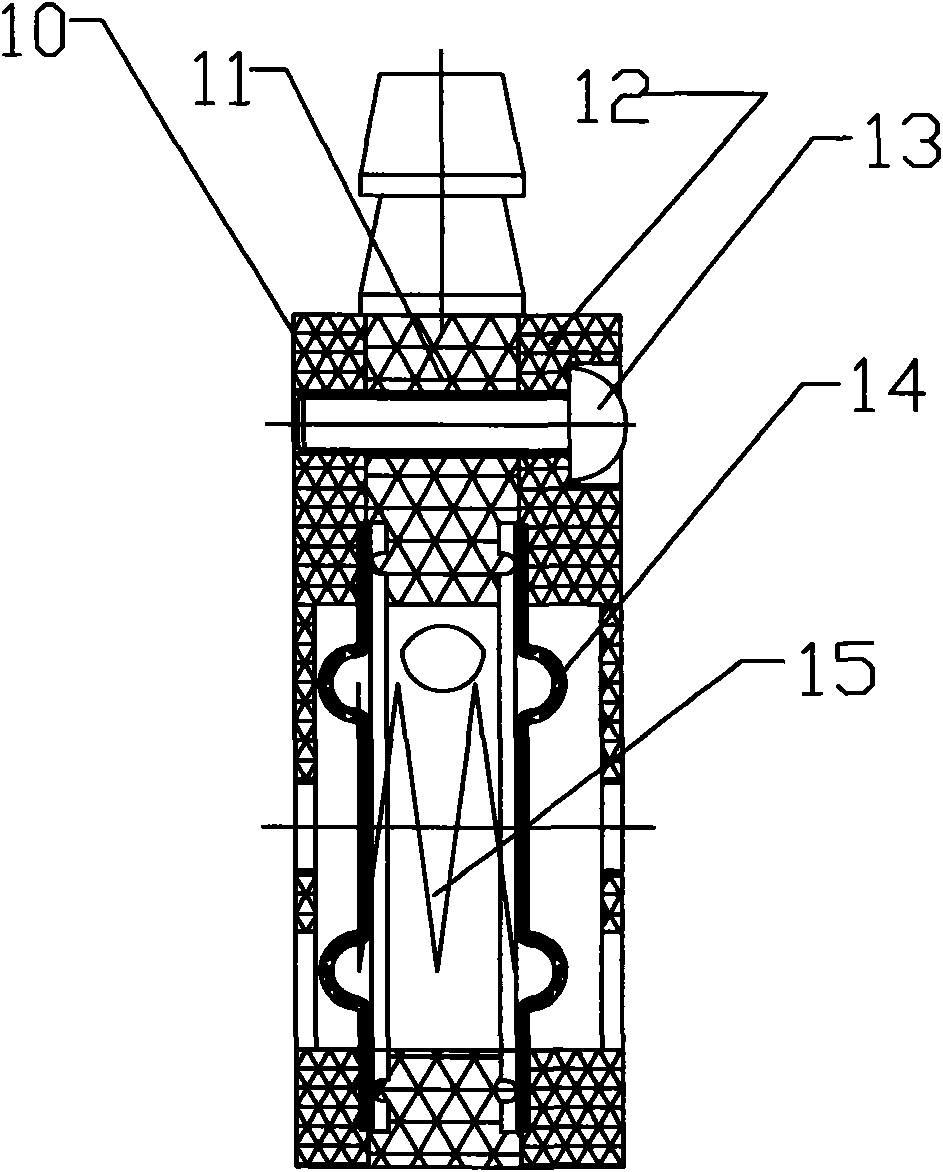

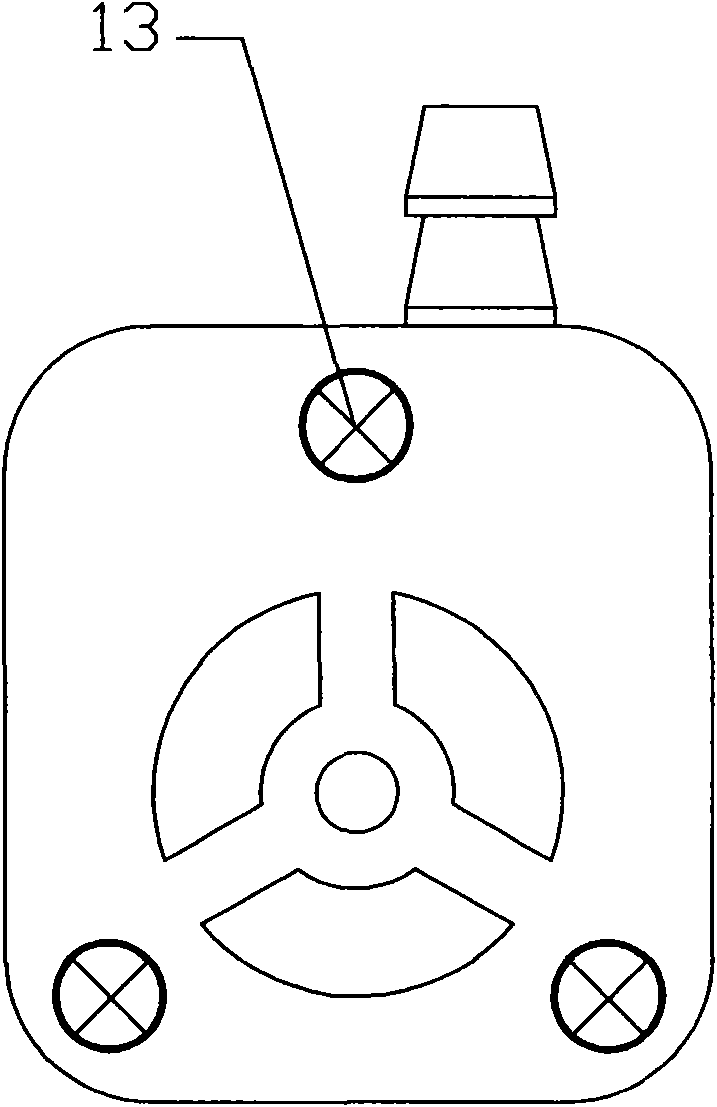

[0038] The present invention will be further described below in conjunction with accompanying drawing. figure 1 , 4Among them, the intelligent constant-flow individual air dust sampler includes a sampling head and an instrument shell, and an intake filter 1, an air pump 3, an air chamber 5, a single-chip microcomputer 7, a battery, and an intake filter 1 are arranged in the instrument shell. The sampling head connected to the air port is equipped with a filter membrane for collecting dust, and its characteristics are: the sampler is also provided with a buffer gas capacity 2, a gas capacity 4, and a flow closed-loop control circuit 16; the gas chamber 5 is provided with an orifice connection Nozzle 5-1, orifice plate 5-2, orifice plate seat 5-3, air chamber diaphragm 5-4, pressure measuring port 5-7 and differential pressure sensor 6; the test end of differential pressure sensor 6 passes through the hose It is connected with the pressure measuring port 5-7 on the gas chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com