Method for determining pump flow without the use of traditional sensors

A pump flow, agitator technology, applied in the field of pump systems, that can solve problems such as reducing flexibility, increasing drive system cost and complexity, and adding failure point costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

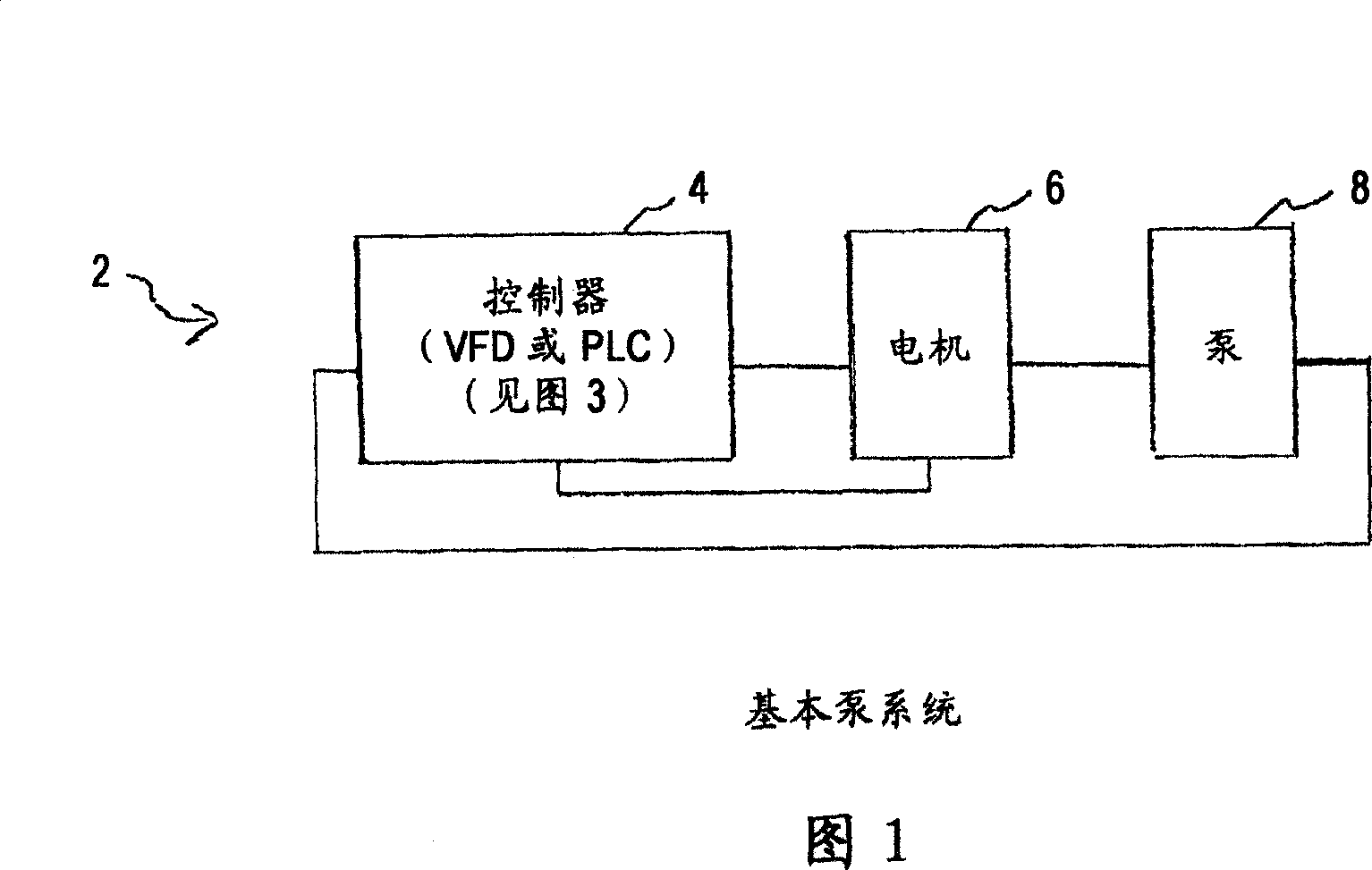

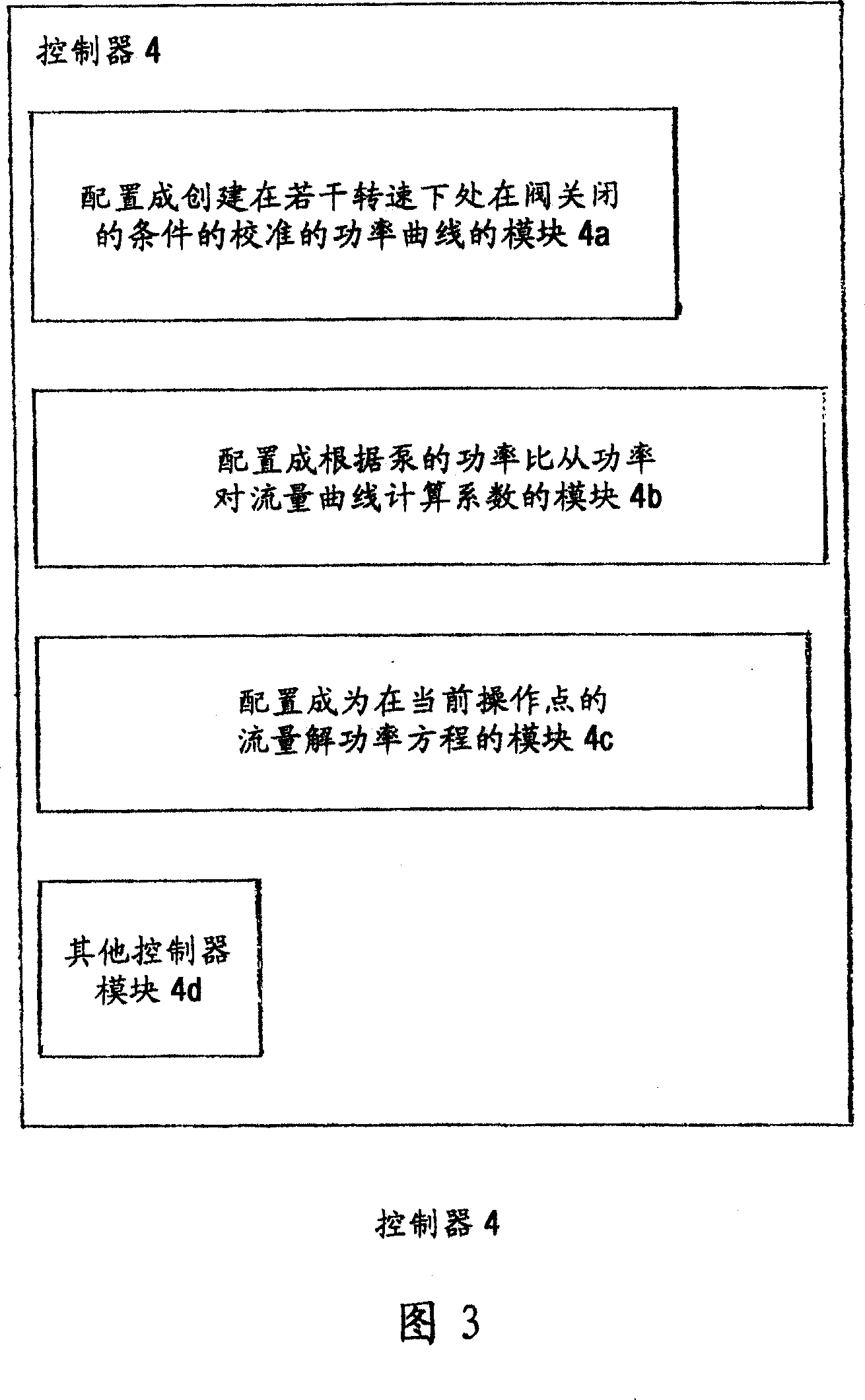

[0036] FIG. 1 shows a basic pump system according to the invention, generally indicated at 2 , with a controller 4 , a motor 6 and a pump 8 . In operation, according to the present invention, the controller 4 is used to determine pump flow without the use of conventional sensors based on a technique consistent with that shown and described herein, wherein the technique creates Calibrate the power curve at the valve closed condition; calculate coefficients from the power versus flow curve based on the power ratio of the pump; and solve the power equation for the flow at the current operating point.

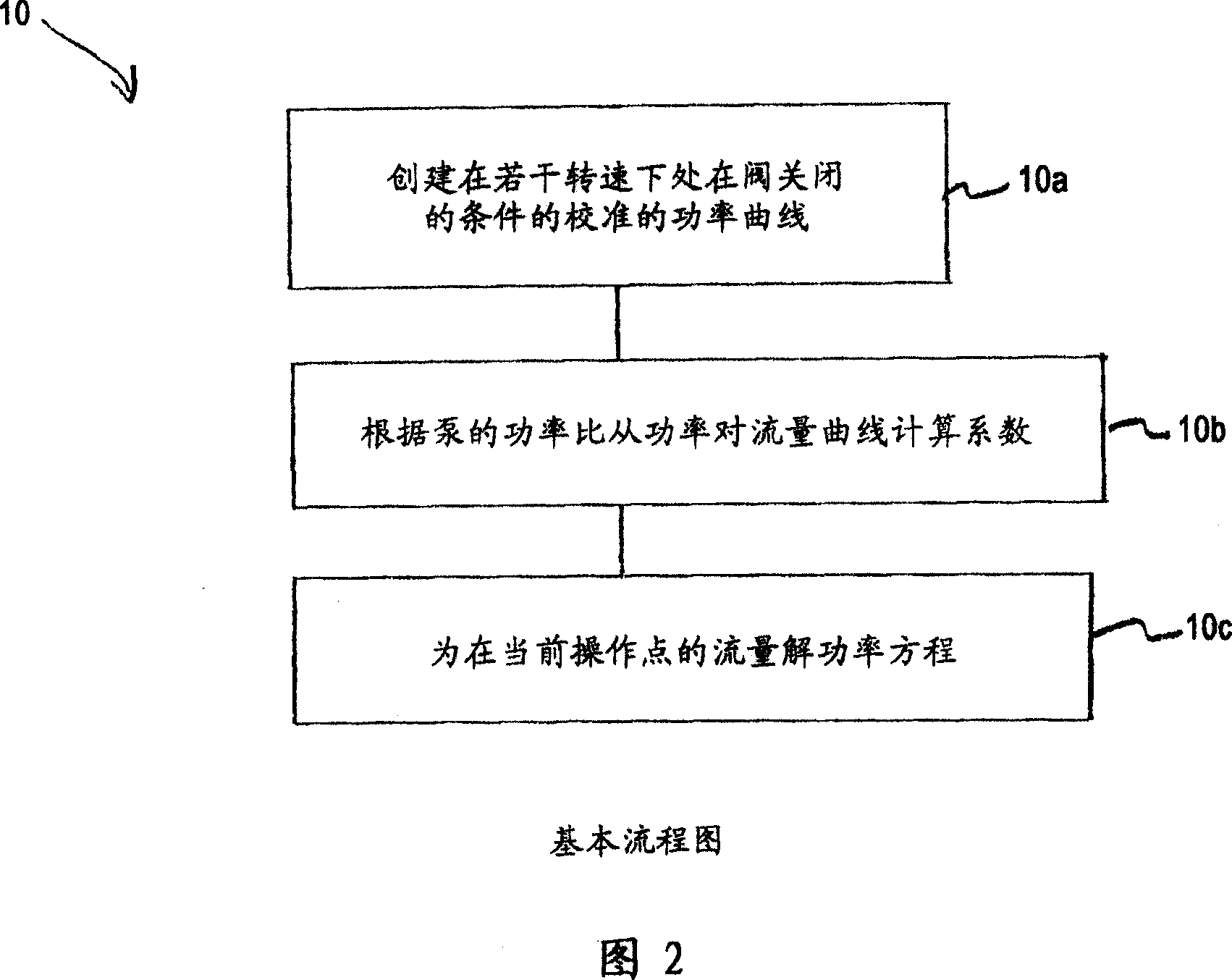

[0037]Figure 2 shows by way of example a flow chart generally indicated at 10 with the basic steps 10a, 10b, 10c of a pump flow determination algorithm that can be implemented by the controller 4 according to the invention. The determined flow value can also be used as an input to a PID control loop to control the flow without the need for an external flow meter or traditional meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com