Adjustment method for steam turbine control valve flows in thermal power plant

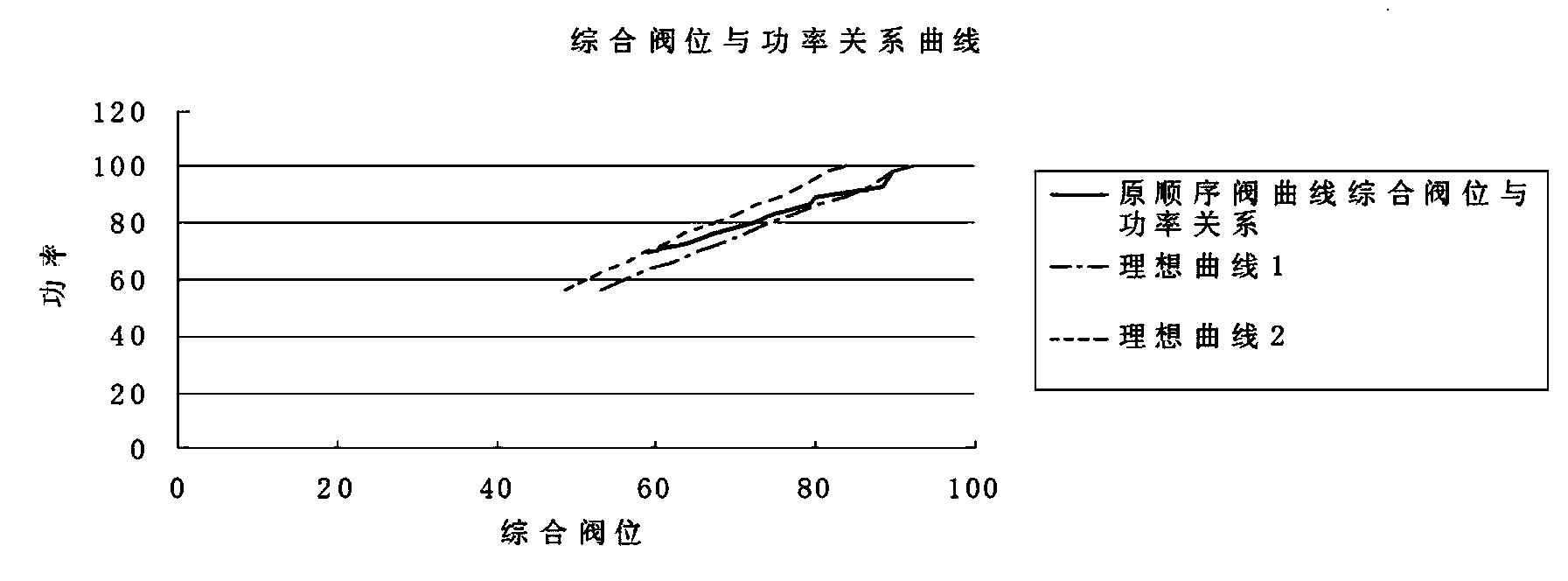

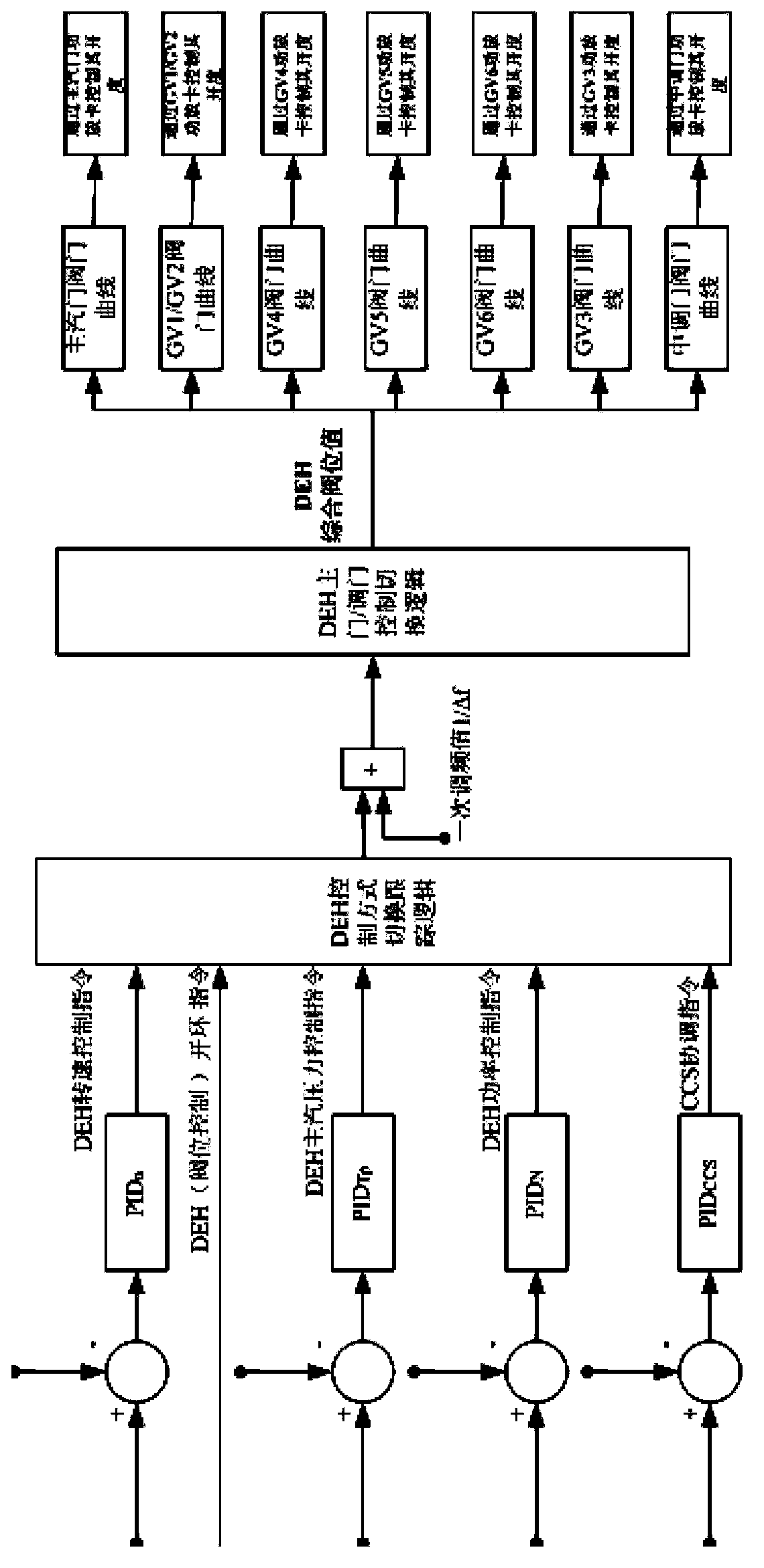

A technology for thermal power plants and adjustment methods, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., and can solve the problems that the unit adjustment performance cannot meet the power grid, sudden load changes, and slow adjustment, so as to facilitate coordinated control and prevent swings , improve the effect of linearization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

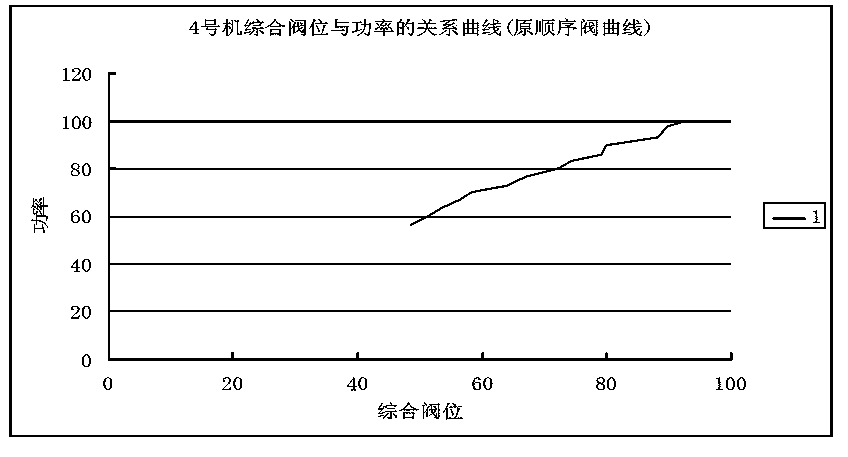

[0048] Based on a subcritical parameter of a thermal power plant, natural circulation, single furnace, one-time intermediate reheating, four-corner tangential combustion, balanced ventilation, solid-state slag discharge, full-suspension structure, metal rain cover on the furnace roof, and tight-fitting closed structure , "II" shape layout steam drum furnace as an example. The boiler can operate at constant pressure, or in a fixed-slip-fixed mode. The boiler can operate with base load or peak load. The pulverizing system adopts five HP-823 medium-speed mills, and the positive pressure direct blowing type pulverizing system of the cold primary fan. Four mills are normally in operation, and one mill is in standby. Under the condition of normal coal incomin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com