Highly functional polyethylene fiber, woven/knitted fabric comprising same, and glove thereof

A polyethylene fiber and polyethylene technology, applied in the direction of gloves, fabrics, fiber chemical characteristics, etc., can solve the problems of decreased operability, inability to increase the drawing speed, uneven filaments, etc., and achieve high thermal insulation and cutting resistance , Improving process passability and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

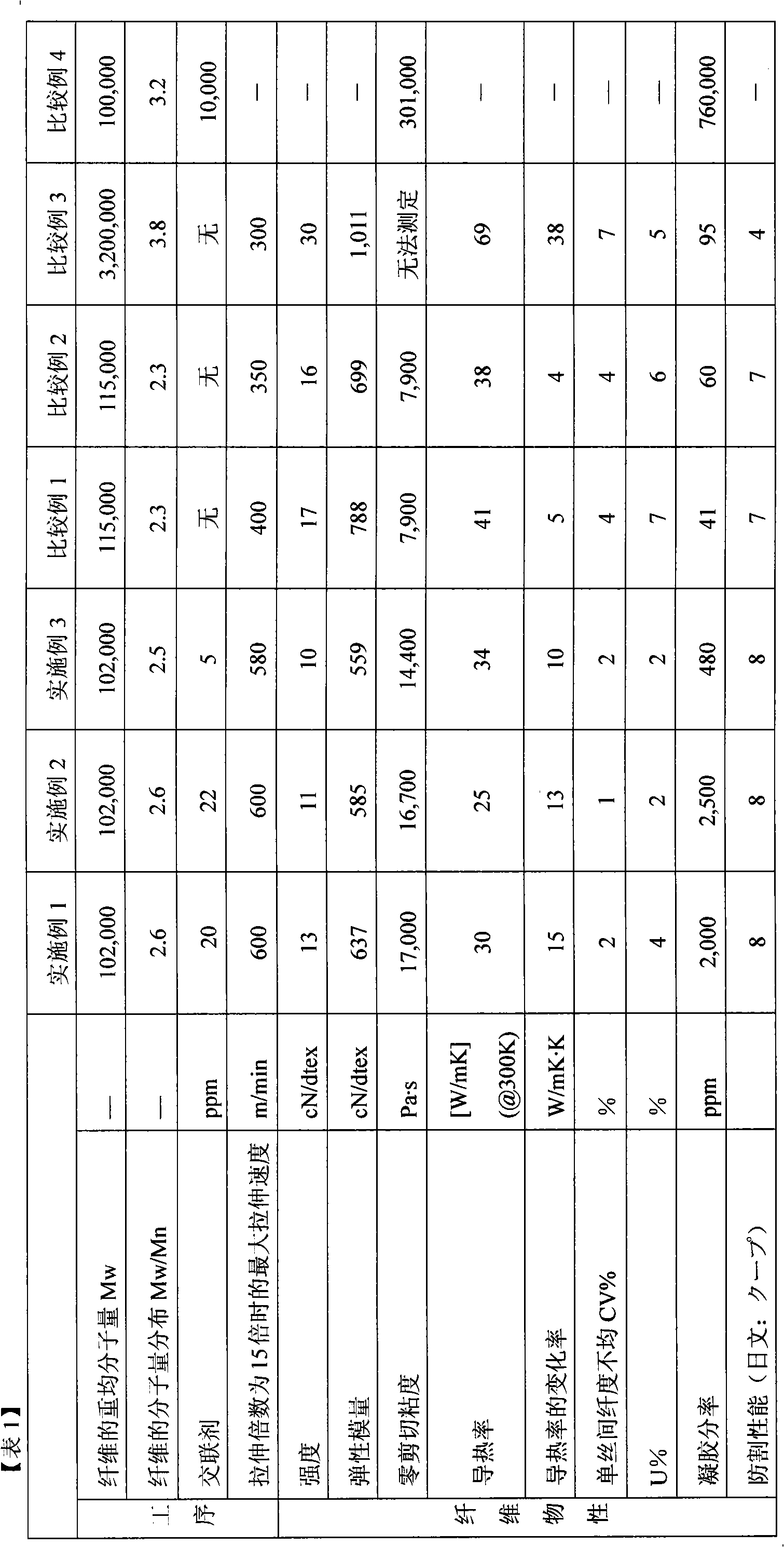

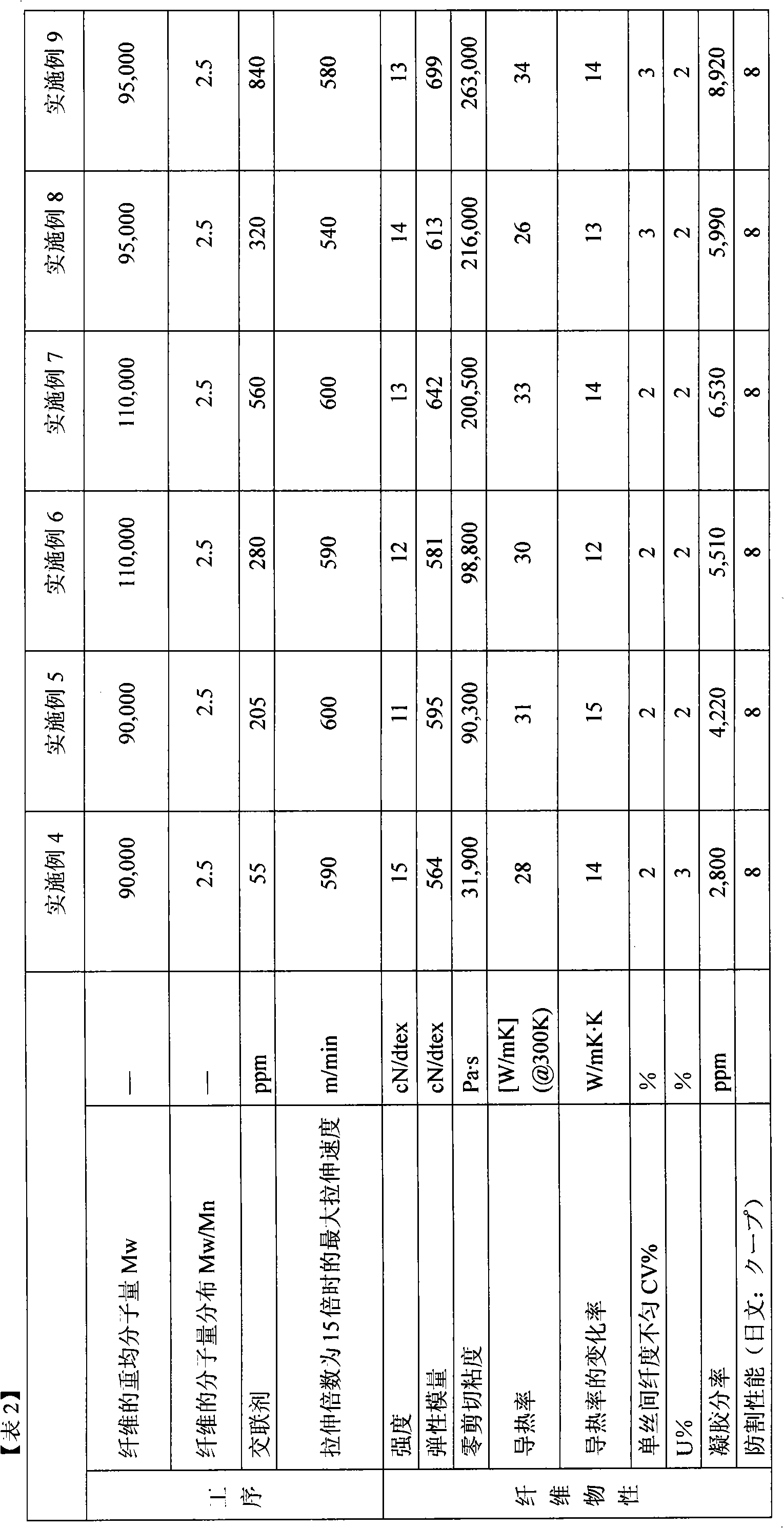

Embodiment 1

[0084] Add 20ppm of 2,5-dimethyl-2,5-di(tert-butyl peroxide base) hexane as a crosslinking agent, using a twin-screw extruder for kneading. This cross-linked polyethylene was extruded at 300° C. from a spinneret having a diameter of 0.8 mm and a number of holes of 10H at a rate of 0.6 g / min per hole discharge. The extruded fibers were passed through a 60 mm-long heat pipe heated to 270° C., quenched with air kept at 20° C., and wound at a speed of 90 m / min to obtain undrawn yarns. The maximum drawing speed (drawing speed at break) of the obtained undrawn yarn at 100° C. and a draw ratio of 15 times was confirmed to be 600 m / min. This undrawn yarn was heated to 100° C., and drawn yarn was obtained at a drawing speed of 300 m / min and a draw ratio of 18 times.

[0085] The obtained fiber was used as a sheath yarn, and a 155 dtex spandex fiber ("Espa (registered trademark)" manufactured by Toyobo Co., Ltd.) was used as a core yarn to obtain a single covered yarn. Using the obta...

Embodiment 2

[0087] The experiment was carried out in the same manner as in Example 1 except that the crosslinking amount described in Table 1 was used to obtain drawn yarns at a draw ratio of 16 times.

Embodiment 3

[0089] The amount of cross-linking agent added was set at 5 ppm, the unstretched yarn was heated to 20°C, moved at 10m / min to perform 2-fold stretching, and then heated to 100°C, and 16-fold stretching was performed. The experiment was carried out in the same manner as in Example 1, except that the stretched yarn was obtained. It should be noted that the maximum drawing speed of the undrawn yarn obtained in Example 3 was 580 m / min at 100° C. and a draw ratio of 15 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| rate of change | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com