Long chain branching polylactic resin and preparation method thereof

A technology of polylactic acid resin and long-chain branching, which is applied in the field of long-chain branched polylactic acid resin and its preparation, can solve problems such as difficulties in continuous industrial production, difficulty in process control, and staying in the laboratory stage, and achieve remarkable results. Strain hardening characteristics, improvement of forming efficiency, and effects of suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

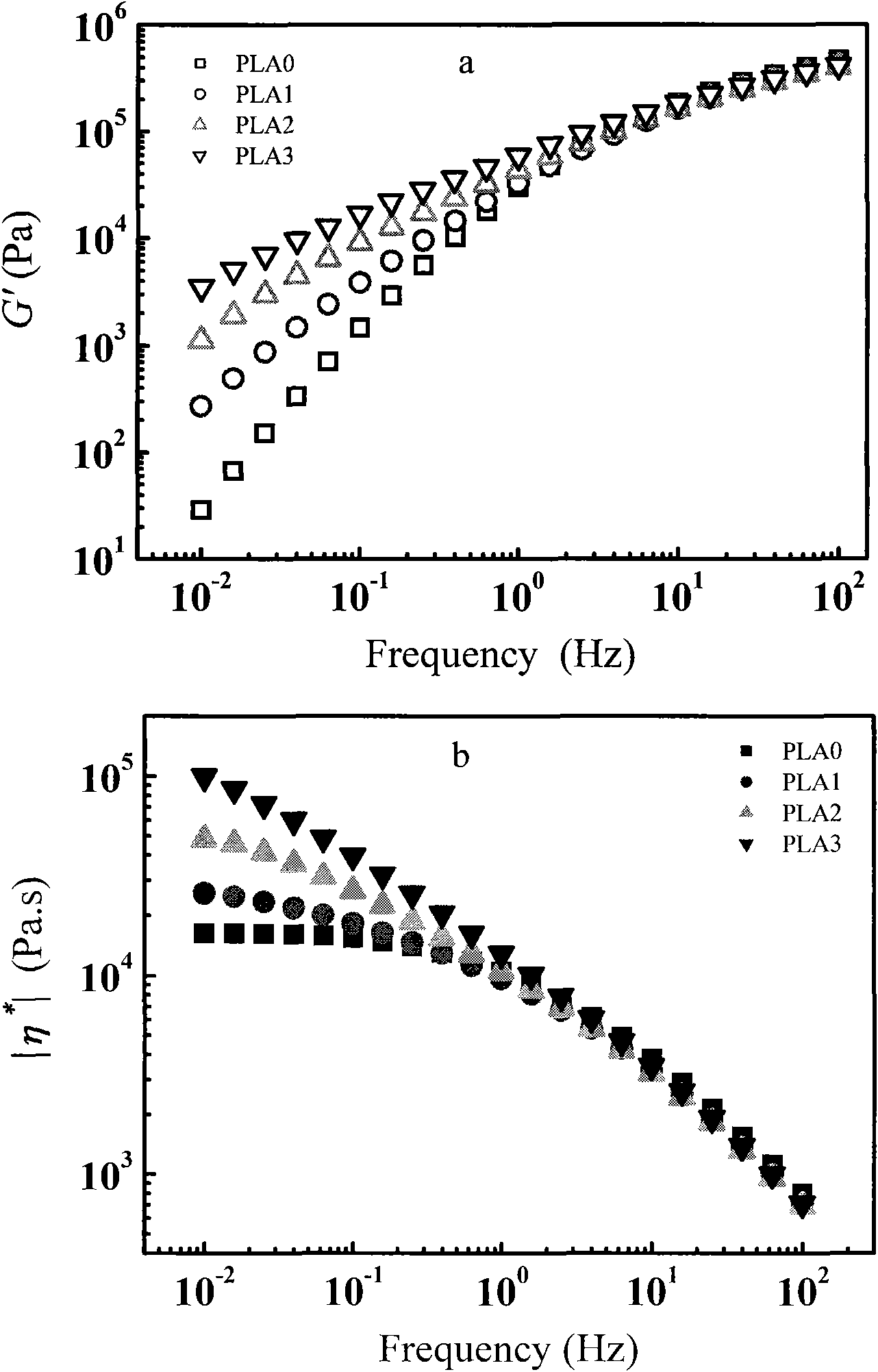

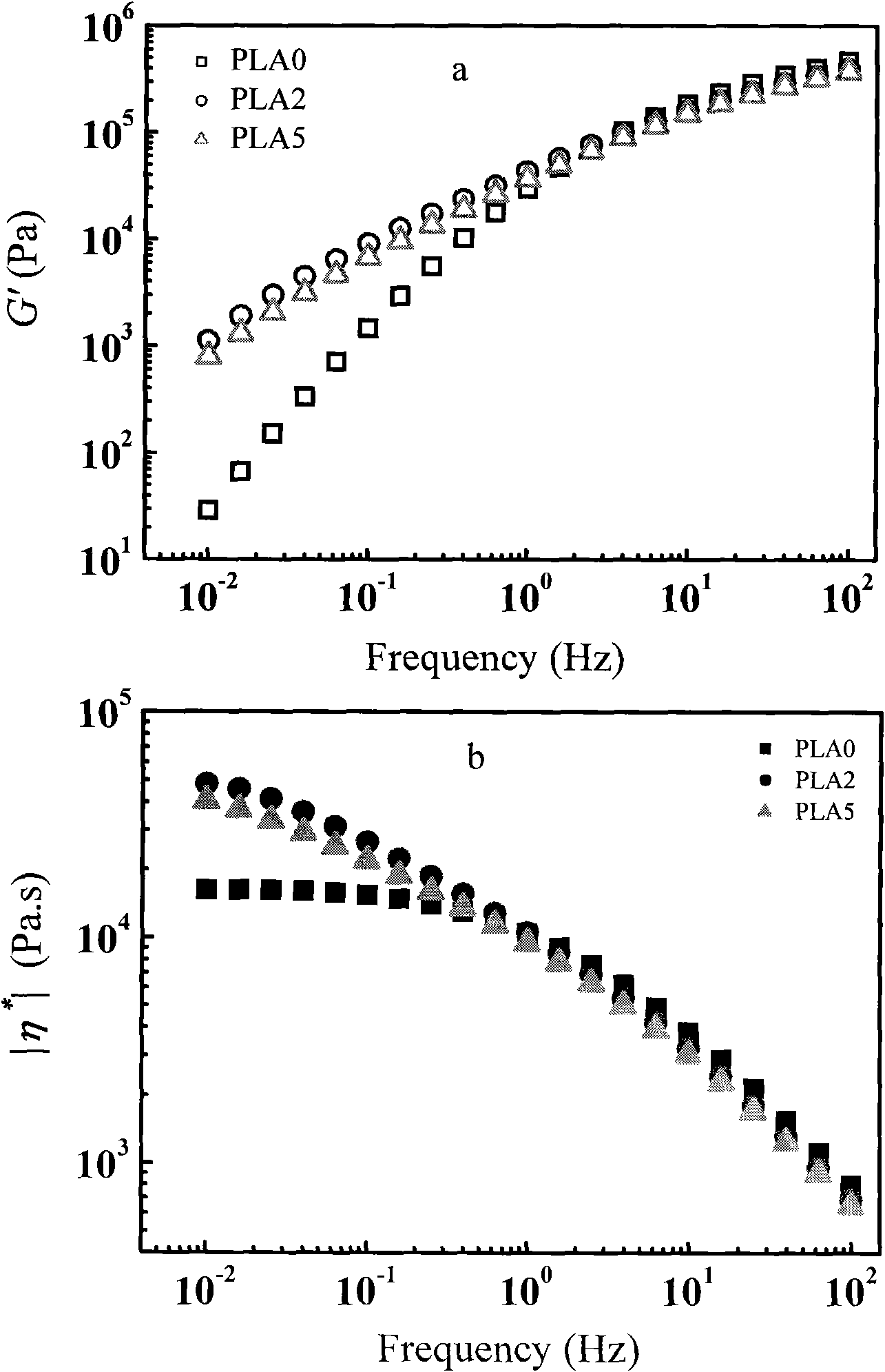

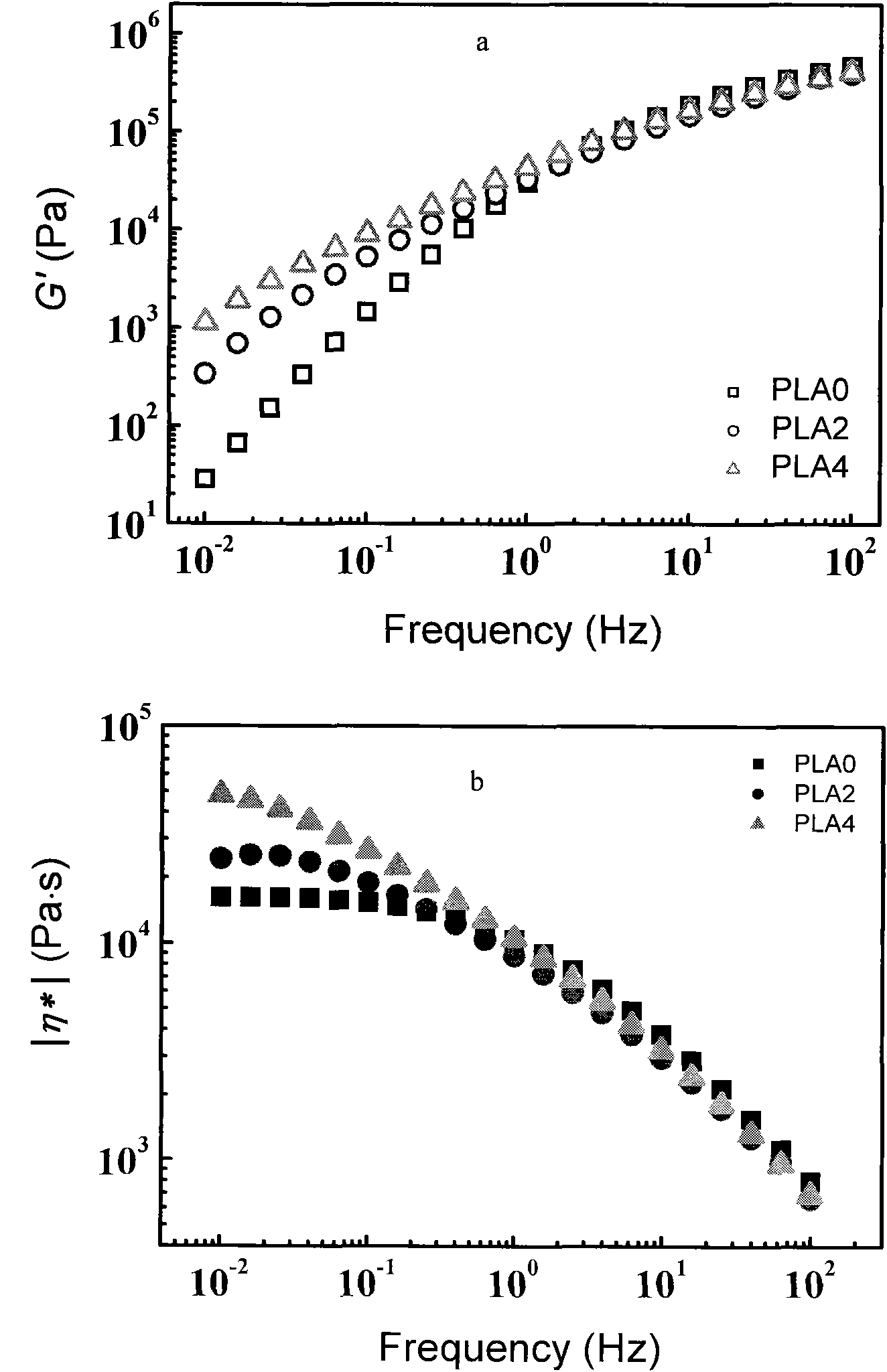

Embodiment 1

[0056] Put 30g of linear PLA, grade 2002D, into a vacuum drying oven with a small amount of phosphorus pentoxide, and dry it in vacuum for 12 hours before use. Weigh 0.03g of initiator BPDH, dissolve BPDH in 20ml of acetone, mix the solution with dried PLA, put it in a fume hood and wait for the solvent to volatilize. The above mixture was placed in a Haake Rheocord90 internal mixer for melting and internal mixing. The banburying time was 12 minutes, the banburying temperature was 160°C, and the rotor speed was 20 rpm. The performance test data are shown in Table 2.

Embodiment 2

[0058] Put 30g of linear PLA, grade 2002D, into a vacuum drying oven with a small amount of phosphorus pentoxide, and dry it in vacuum for 12 hours before use. Weigh 0.09g of initiator BPDH, dissolve BPDH in 20ml of acetone, mix the solution with dried PLA, put it in a fume hood and wait for the solvent to volatilize. The above mixture was placed in a Haake Rheocord90 internal mixer for melting and internal mixing. The banburying time was 12 minutes, the banburying temperature was 160°C, and the rotor speed was 20 rpm. The performance test data are shown in Table 2.

Embodiment 3

[0060] Put 30g of linear PLA, grade 2002D, into a vacuum drying oven with a small amount of phosphorus pentoxide, and dry it in vacuum for 12 hours before use. Weigh 0.15 g of initiator BPDH, dissolve BPDH in 20 ml of acetone, mix the solution with dried PLA, and put it in a fume hood until the solvent volatilizes. The above mixture was placed in a Haake Rheocord90 internal mixer for melting and internal mixing. The banburying time was 12 minutes, the banburying temperature was 160°C, and the rotor speed was 20 rpm. The performance test data are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com