Forming method of amorphous alloy

A technology of amorphous alloy and ingot casting, which is applied in the field of amorphous alloy forming, can solve the problems of reducing production efficiency and prolonging the casting cycle of amorphous alloy, and achieve the effects of improving production efficiency, good product quality, and reducing the time for vacuum acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example is used to illustrate the method for forming the amorphous alloy of the present invention.

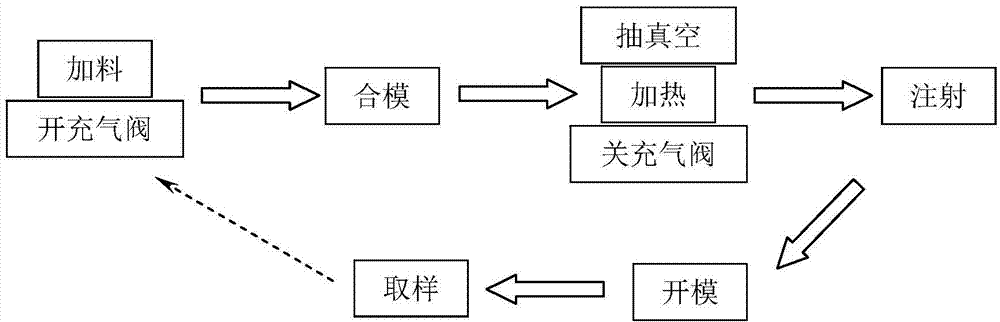

[0043] Use the die-casting machine disclosed in CN201231307, according to figure 1 The flow shown is for amorphous alloy forming.

[0044] Open the argon gas filling valve to fill the vacuum chamber and crucible with argon. After measurement, the oxygen content in the vacuum chamber is 6% by volume. Composition of ingredients as Zr 53 Al 10 Cu 30 Ni 7 The amorphous alloy ingot is fed into the crucible, and the mold is clamped at the same time. After keeping the vacuum chamber filled with argon for 2 seconds, start to heat the amorphous alloy ingot in the crucible by induction heating at a heating rate of 50°C / s. After 2 seconds from the start of heating, close the argon gas filling valve to stop filling with argon, and start to use a vacuum pump to evacuate at the same time, and simultaneously evacuate the mold and the injection channel. The pumping speed of ...

Embodiment 2

[0049] This example is used to illustrate the method for forming the amorphous alloy of the present invention.

[0050] Use the die-casting machine disclosed in CN201231307, according to figure 1 The flow shown is for amorphous alloy forming.

[0051] Open the argon filling valve to fill the vacuum chamber and crucible with argon, and make the composition into Ti 50 Ni 20 Cu 25 sn 5 The amorphous alloy ingot is fed into the crucible, and the mold is clamped at the same time. Start to heat the amorphous alloy ingot in the crucible by induction heating, and the heating rate is 50°C / s. After heating starts for 0 s, close the argon gas filling valve, and start vacuuming with the vacuum pump, simultaneously vacuuming the mold and the injection channel. The pumping speed of the vacuum pump can reduce the vacuum pressure of the vacuum chamber to below 1000Pa within 5 seconds. Vacuumize to reach a vacuum pressure of 1000Pa. Ti 50 Ni 20 Cu 25 sn 5 The melting point of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com