Brick/block/paver unit and method of production therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

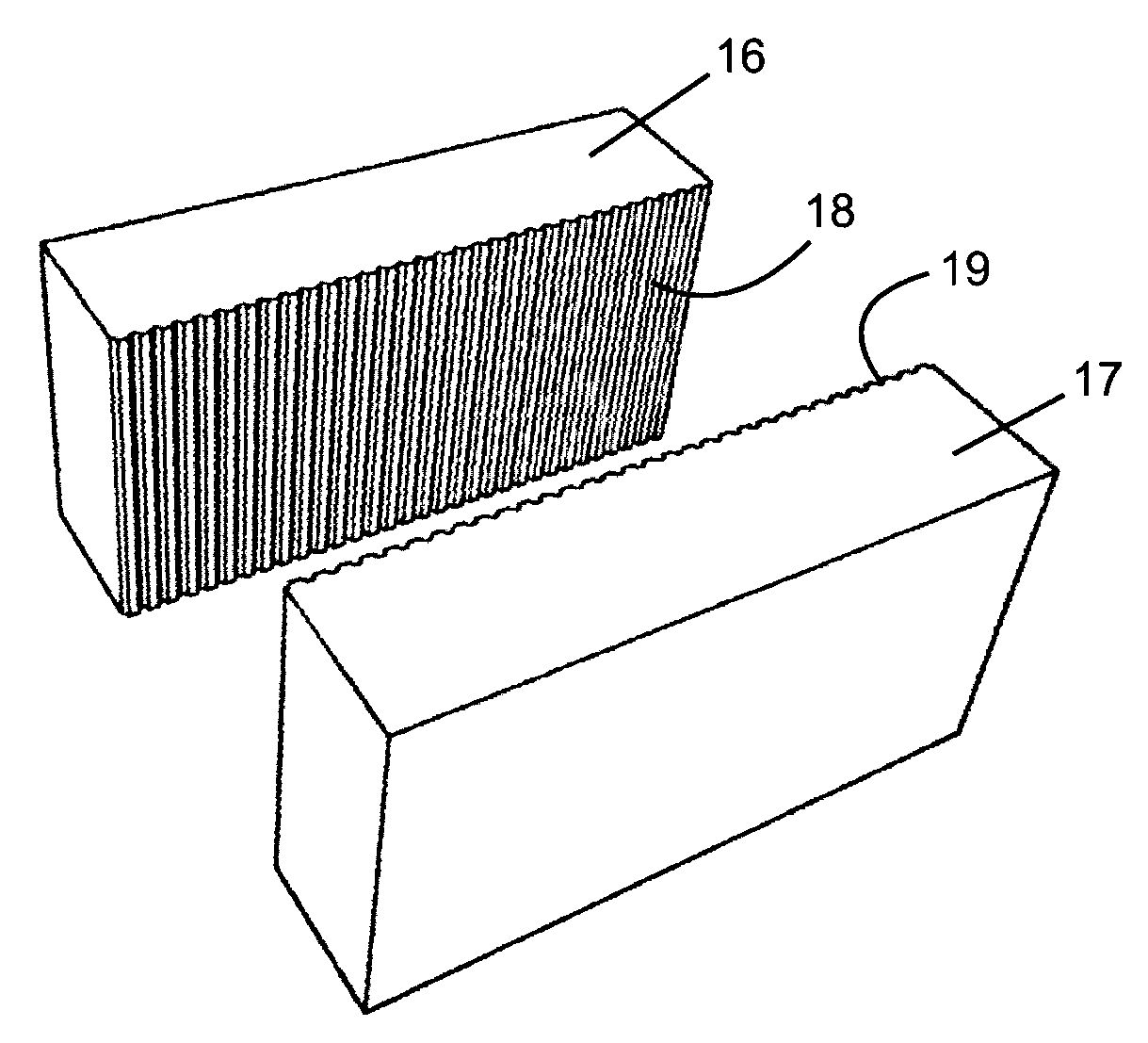

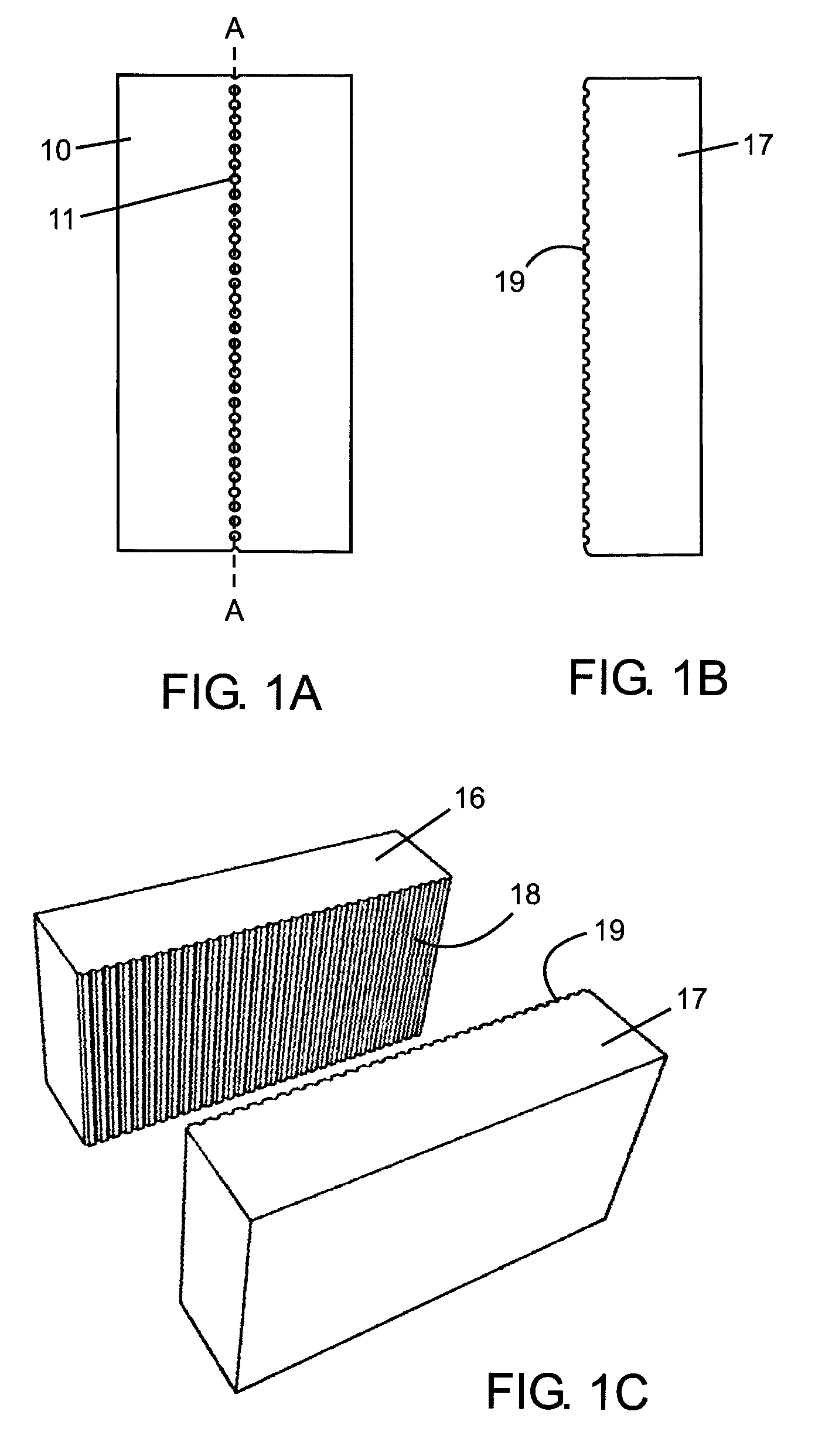

[0081]Referring to FIGS. 1A to 1C, base block 10 has a series of regularly-spaced identical perforations 11 (only one labeled) extending entirely through the base block from one side to the opposed side. The perforations have circular cross-sections. The series of perforations is arranged in a straight line A-A, along which the base block may be split by a light shock. On splitting the base block, two virtually identical standard building blocks 16,17 are produced, having textured faces 18,19, respectively. The textured faces have a consistent and reproducible uniform striated appearance as a result of the arrangement of regularly-spaced identical perforations in the base block.

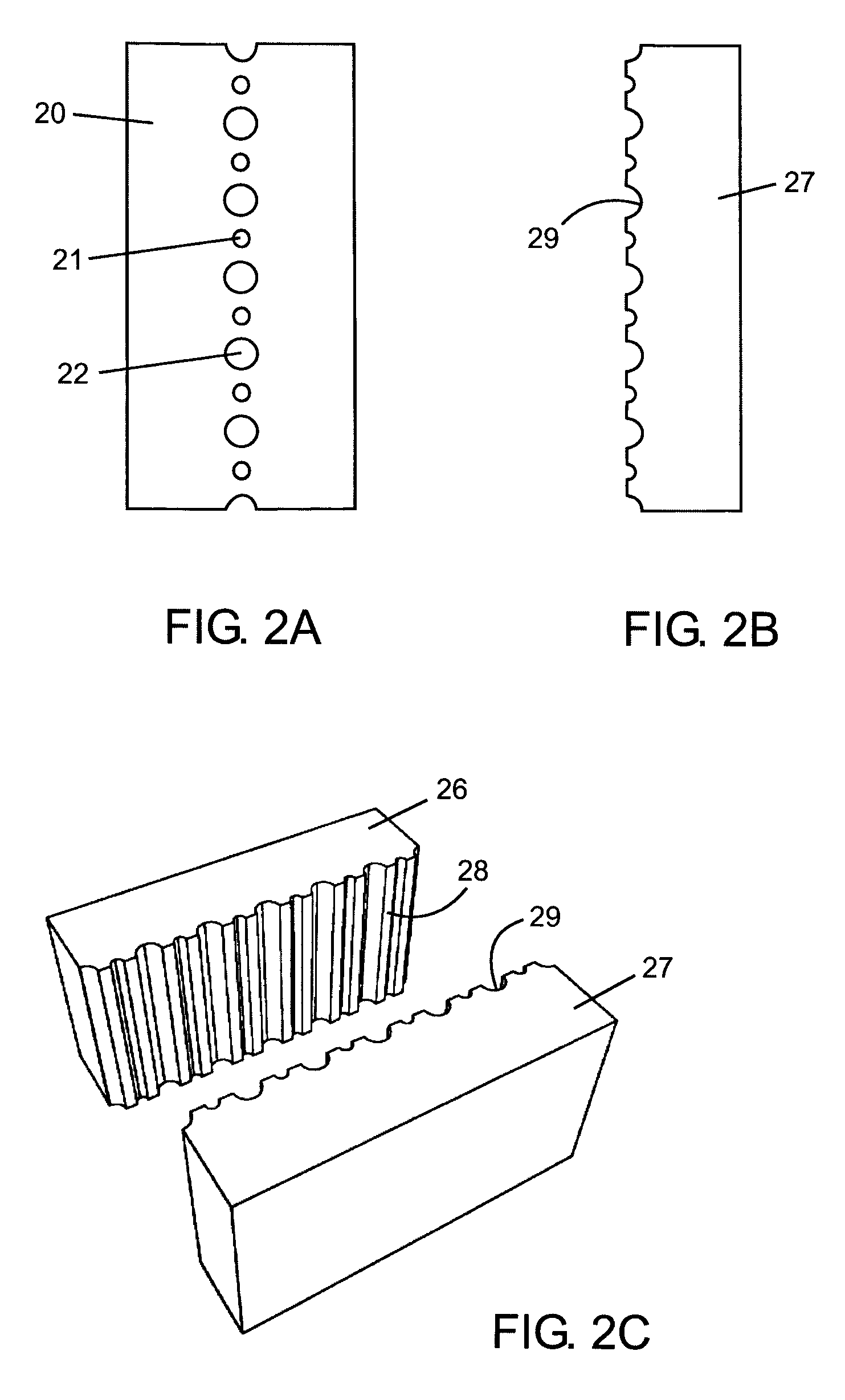

[0082]Referring to FIGS. 2A to 2C, base block 20 has a series of two types of regularly-spaced perforations 21,22 (only one of each type labeled) extending entirely through the base block from one side to the opposed side. Both types of perforations have circular cross-sections, although perforations 21 have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com