Vertical shaft impact crusher

A vertical shaft impact and crusher technology, which is applied in mechanical material recycling, grain processing, plastic recycling, etc., can solve the problems of poor crushing effect, poor material crushing effect, and no screening of materials with different specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

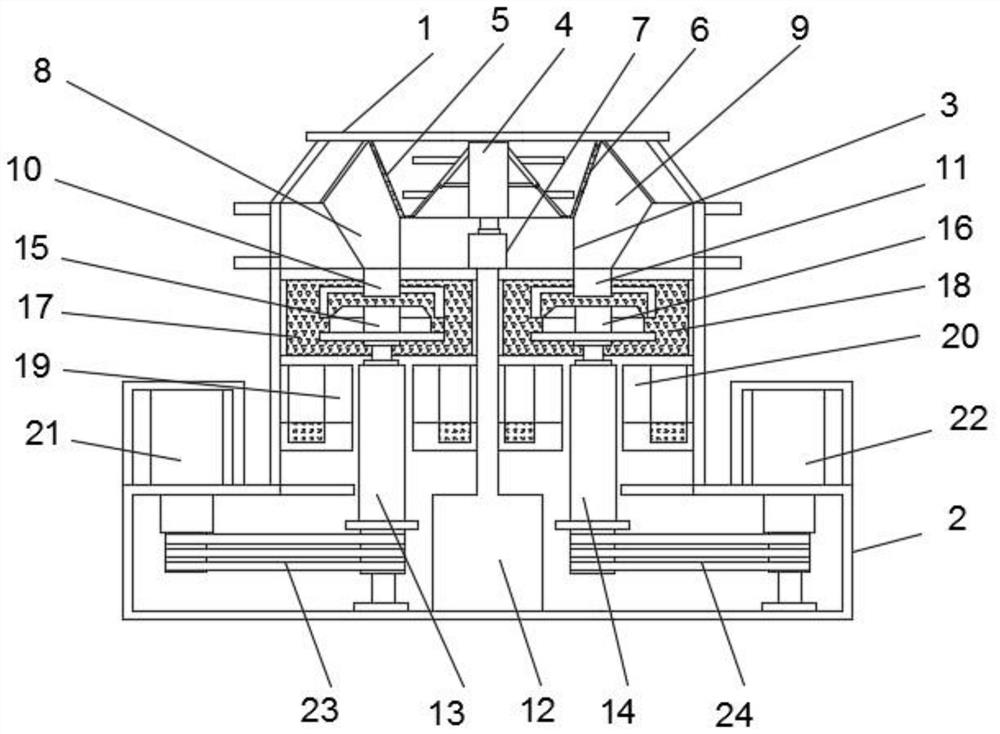

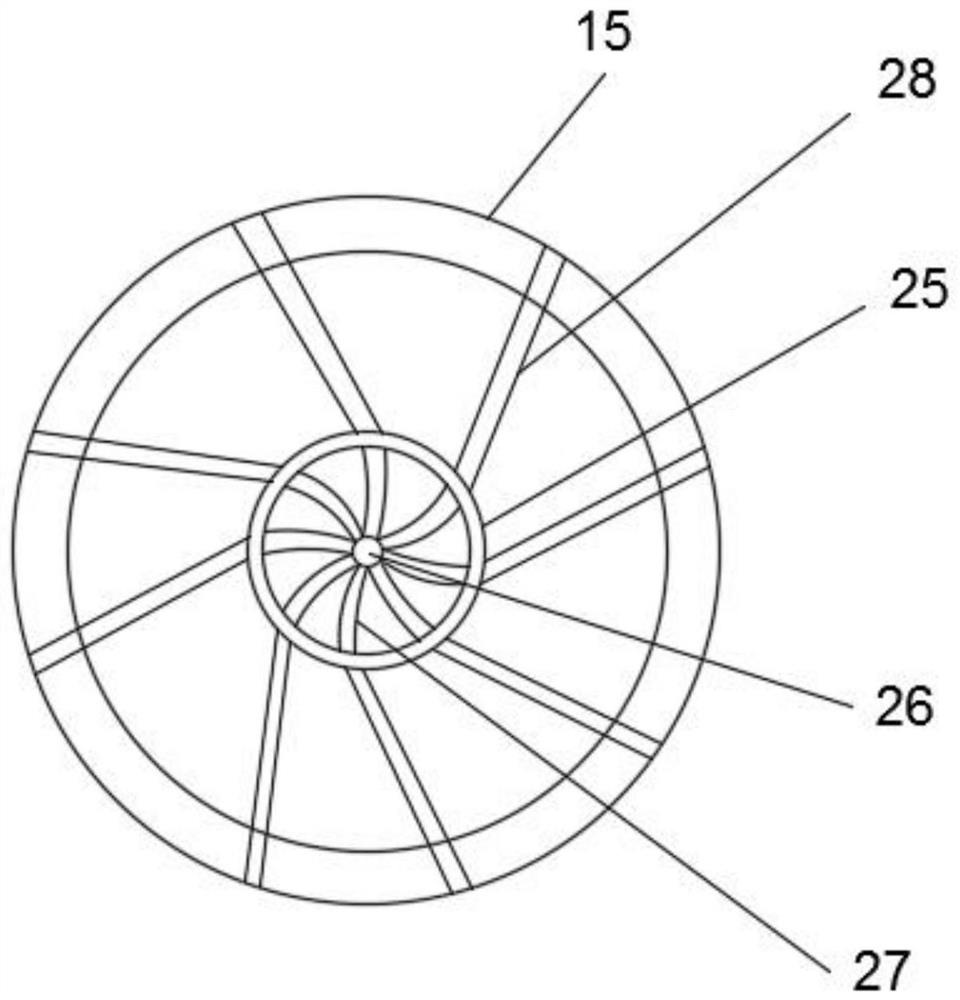

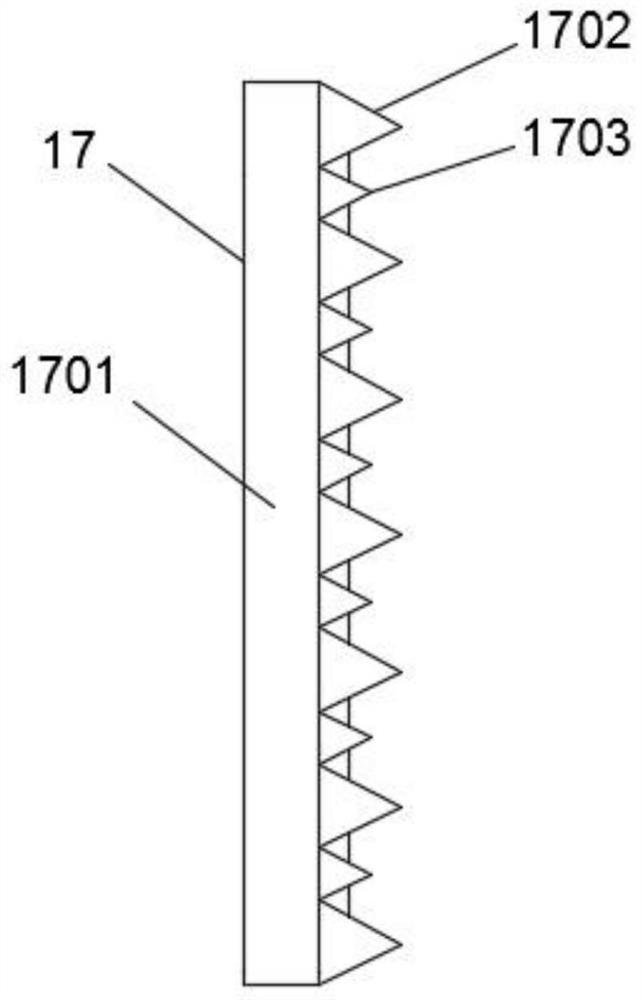

[0038] like Figure 1-7 As shown, a vertical shaft impact crusher includes a crusher body 1, a base 2, a stirring mechanism 4, a first crushing mechanism 17 and a second crushing mechanism 18, and the base 2 is fixedly installed at the lower end of the crusher body 1, A partition plate 12 is fixedly installed in the interior of the base 2 near the middle, the upper end of the partition plate 12 is installed with a support base 3, and the stirring mechanism 4 is installed at the upper end of the support base 3 close to the middle position, so Both sides of the stirring mechanism 4 are slidably connected with a first support plate 35 , the interior of the first support plate 35 is connected with a third support plate 37 at a position close to the bottom, and the first support plate 35 is close to the bottom of the stirring mechanism 4 . A second support plate 36 is fixedly installed on one side, a support transverse plate 30 is fixedly installed in the interior of the stirring m...

Embodiment 2

[0050] The working method of the vertical shaft impact crusher includes the following steps:

[0051] Step 1: The material is transported to the inside of the crusher body 1 through the feeding port, the material enters between the first filter plate 5 and the second filter plate 6, the first drive motor 7 is started, and the first drive motor 7 drives the rotation. The column 401 rotates counterclockwise, and the stirring mechanism 4 is driven to rotate counterclockwise through the rotating column 401;

[0052] Step 2: Activate the air cylinder 31, move the lifting column 33 upward through the air cylinder 31 and the driving column 32, the upward movement of the lifting column 33 drives the slide plate 34 to move upward, the slide plate 34 drives the first support plate 35 to move upward, and the first support plate 35 drives The second support plate 36 moves upward, the first support plate 35 is abutted with the third support plate 37 through the third slider and the slot 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com