Slim hole large-grain mechanical type side-wall coring device

A mechanical, large particle technology, applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems of incomplete core, large porosity, unfavorable identification and analysis, etc. The effect of angle and force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

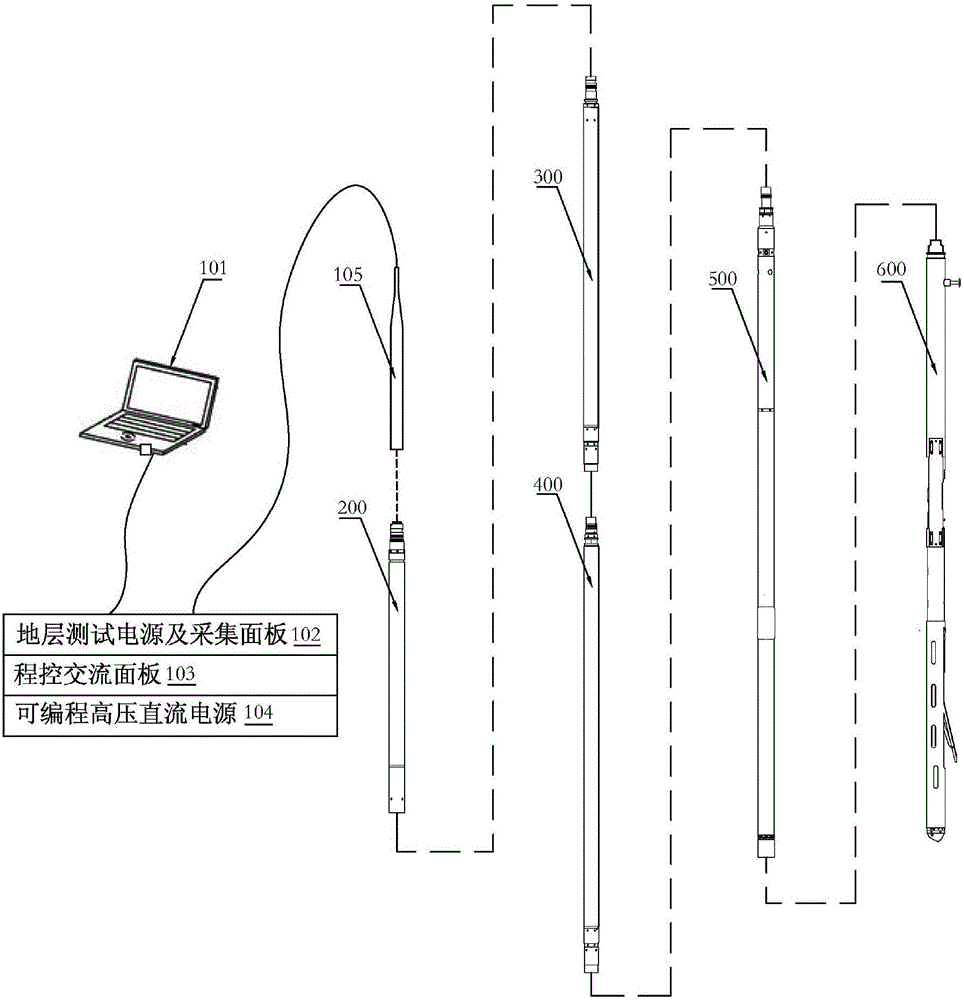

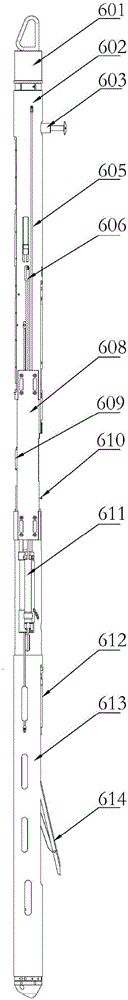

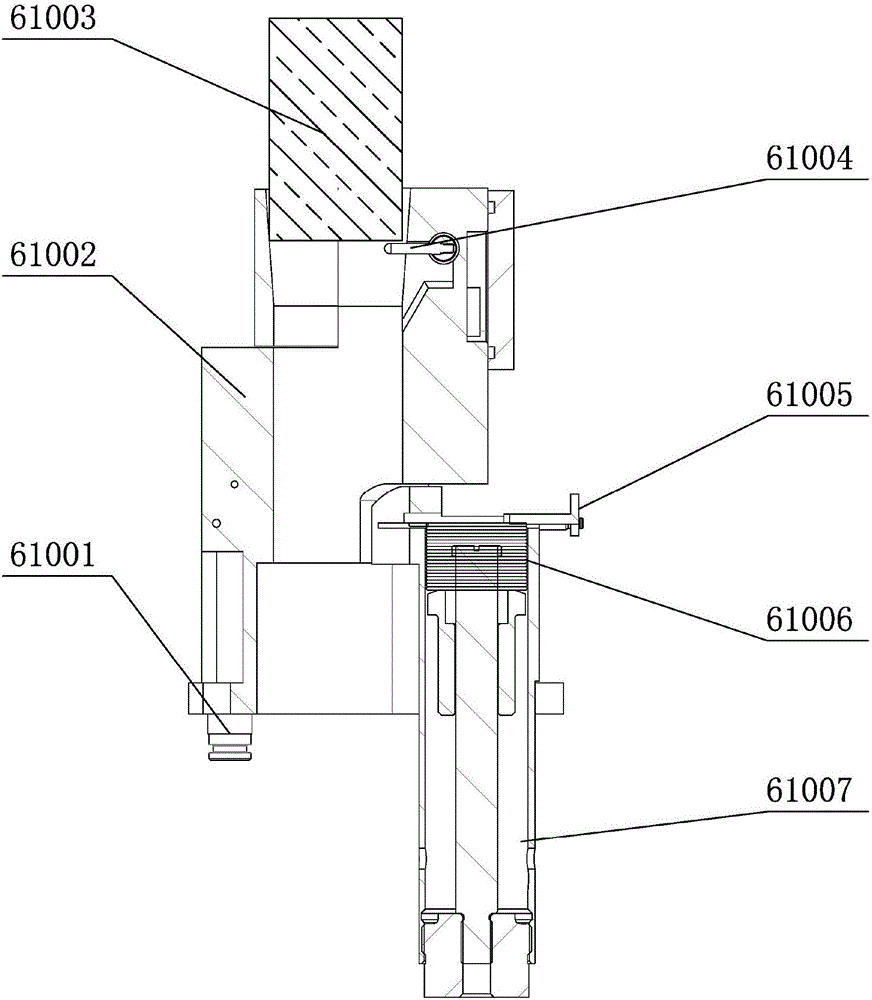

[0019] Small hole large particle mechanical sidewall coring device (MSC-127) is mainly composed of ground control system, π mechanical sidewall coring software (software copyright registration number: 2015SR265183), communication short section 200, power supply section 300, electronic section 400, hydraulic section 500, and mechanical section 600. The ground control system and the downhole instrument are connected through the seven-core logging cable and the bridle 105. The communication sub-section 200 and the power section 300, the power section 300 and the electronic section 400, the electronic section 400 and the hydraulic section 500 respectively adopt electronic pressure-bearing joints and threaded joints. The hydraulic joint 500 and the mechanical joint 600 are connected by electronic pressure-bearing joints, hydraulic quick joints and threaded rings.

[0020] The ground control system is composed of industrial computer 101, formation test power supply and acquisition p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com