Vacuum glass and preparation method thereof

A vacuum glass and glass technology, which is applied in the field of vacuum glass and its preparation, can solve the problems of easy loosening of the suction nozzle, easy decline of vacuum degree, and low service life, so as to prevent the decline of vacuum degree, prolong the service life and improve the strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

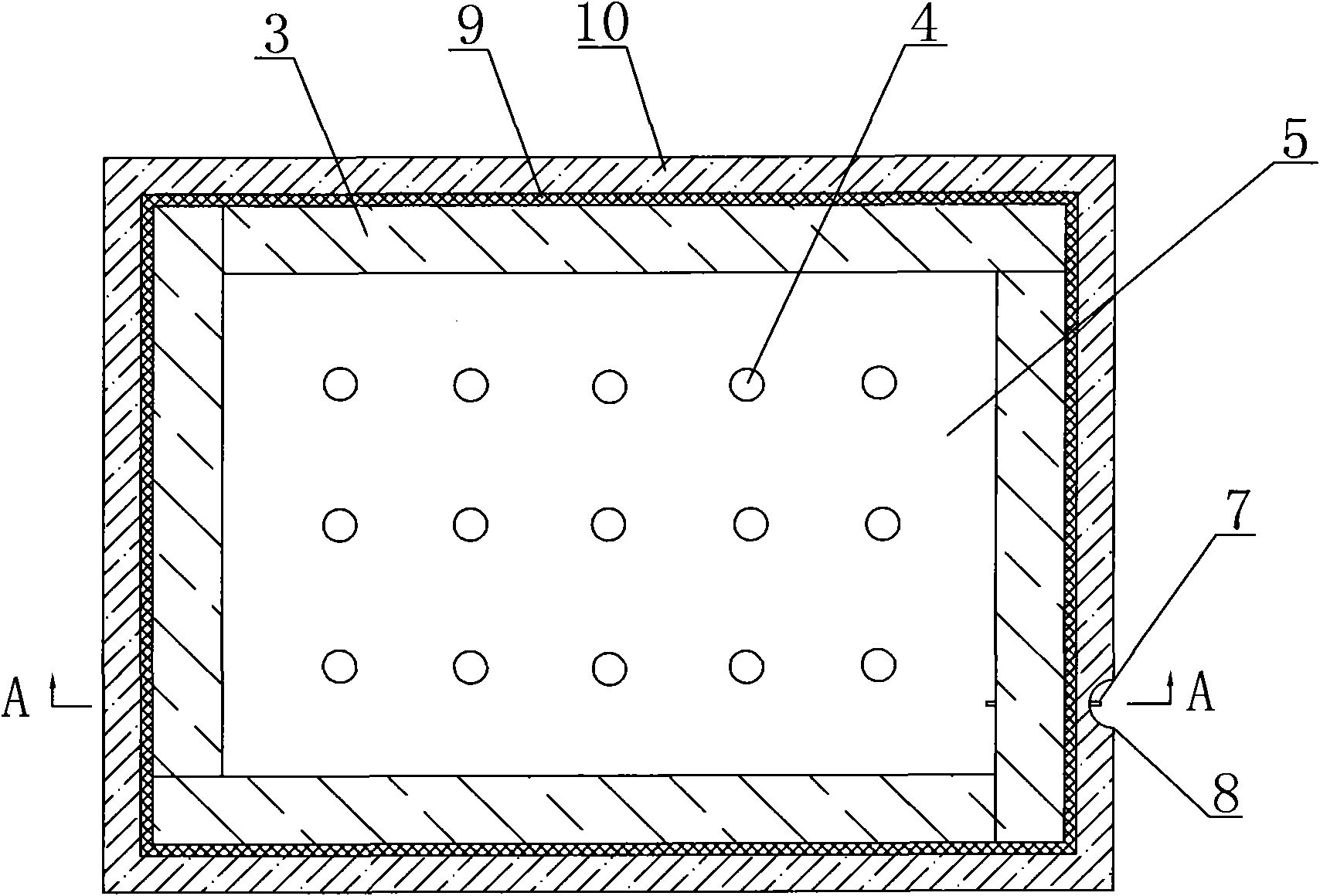

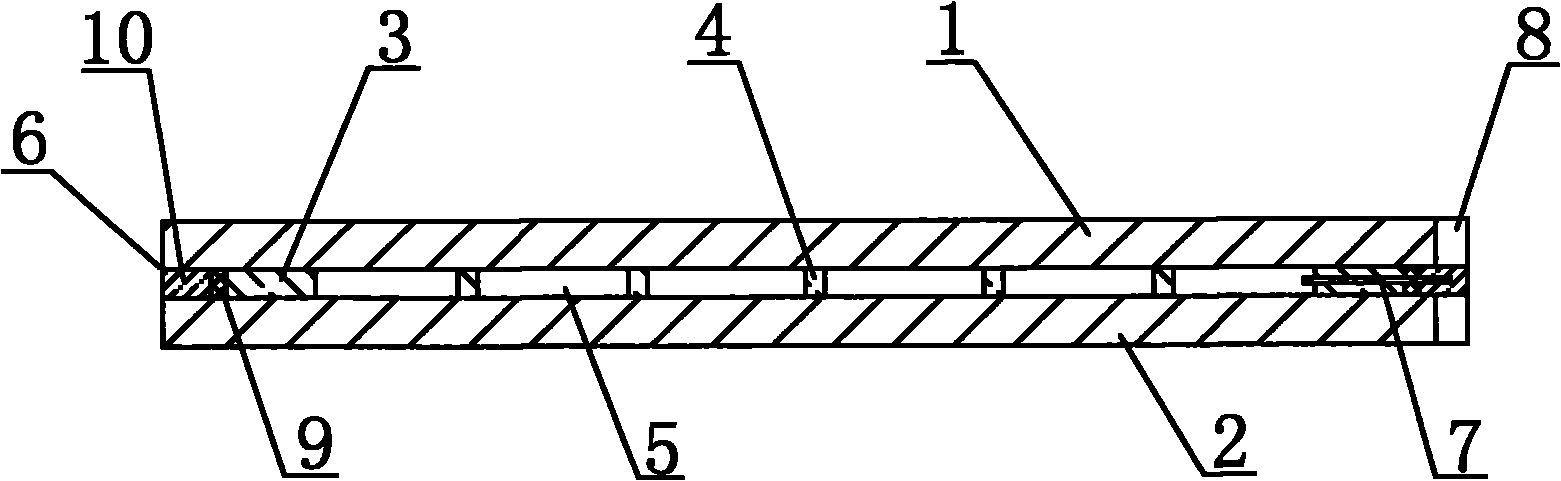

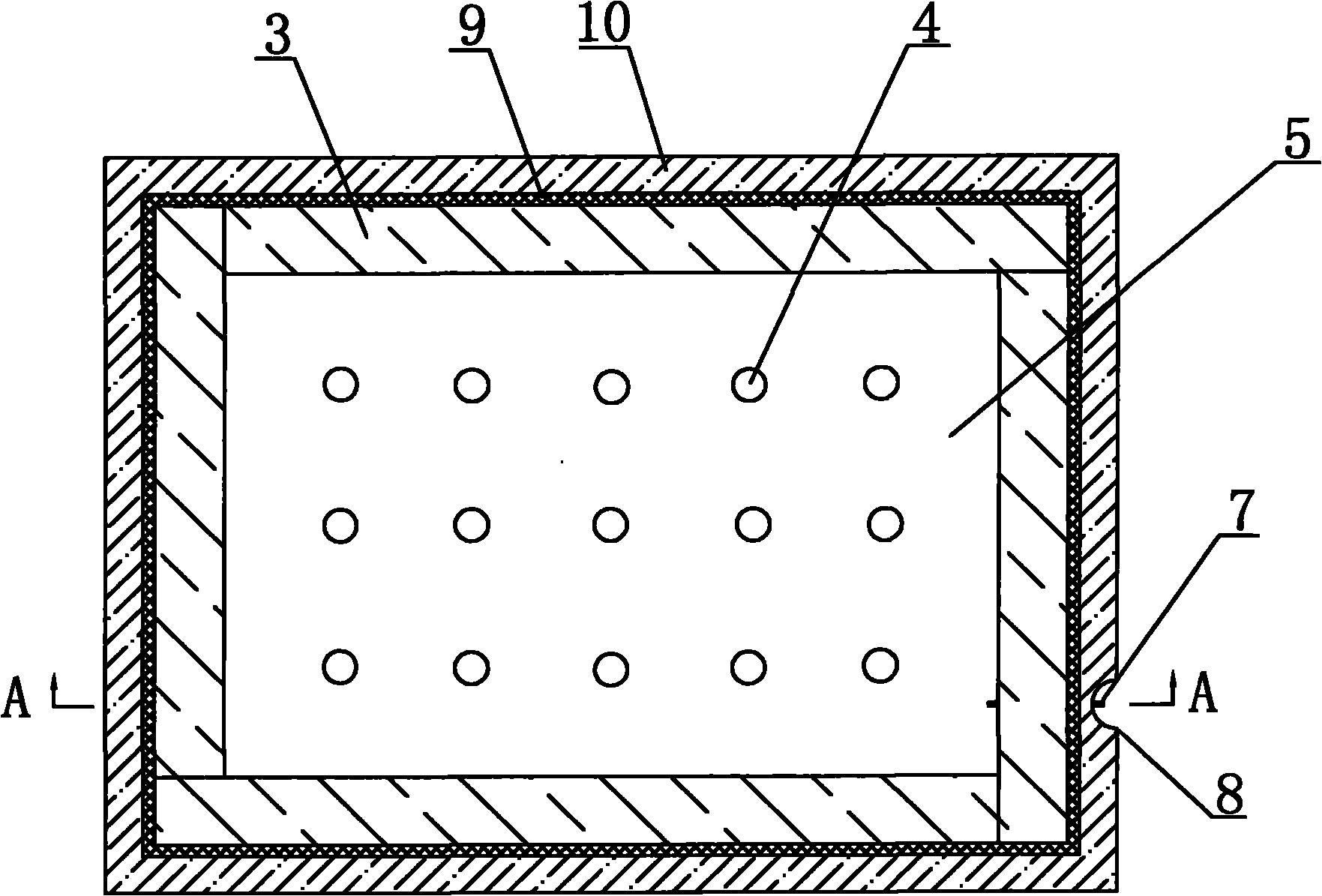

Image

Examples

Embodiment Construction

[0020] A preparation method of vacuum glass, the preparation steps are:

[0021] Step 1. First take two pieces of glass of equal size. Both pieces of glass can be made of white glass. In order to improve the heat insulation effect, a combination of one piece of white glass and one piece of LOW-E glass can also be used. Set a semicircular notch with a radius of 4-6mm at the corresponding position on the edge of the selected two pieces of glass, generally set at 5mm, and prepare it for later use;

[0022] Step 2: Take a piece of glass that has been processed in Step 1, and use an adhesive to set support points and glass seals on the glass. The supporting point is columnar, and its cross section can be circular, square or other shapes. Stick the support points in the middle of the glass in an array, and stick the glass seal around the edge of the glass. Be careful not to go beyond the edge. Leave a distance of 8-12mm, that is, the distance between the outer edge of the glass sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com