Recyclable shot blasting device

A technology of shot blasting and equipment, which is applied in the direction of metal processing equipment, used abrasive processing devices, abrasive jetting machine tools, etc., can solve problems affecting the service life of the device, fracture or damage, and affect the safe use of the rotating cylinder, etc., to improve Lifespan, effect of preventing breakage or shattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

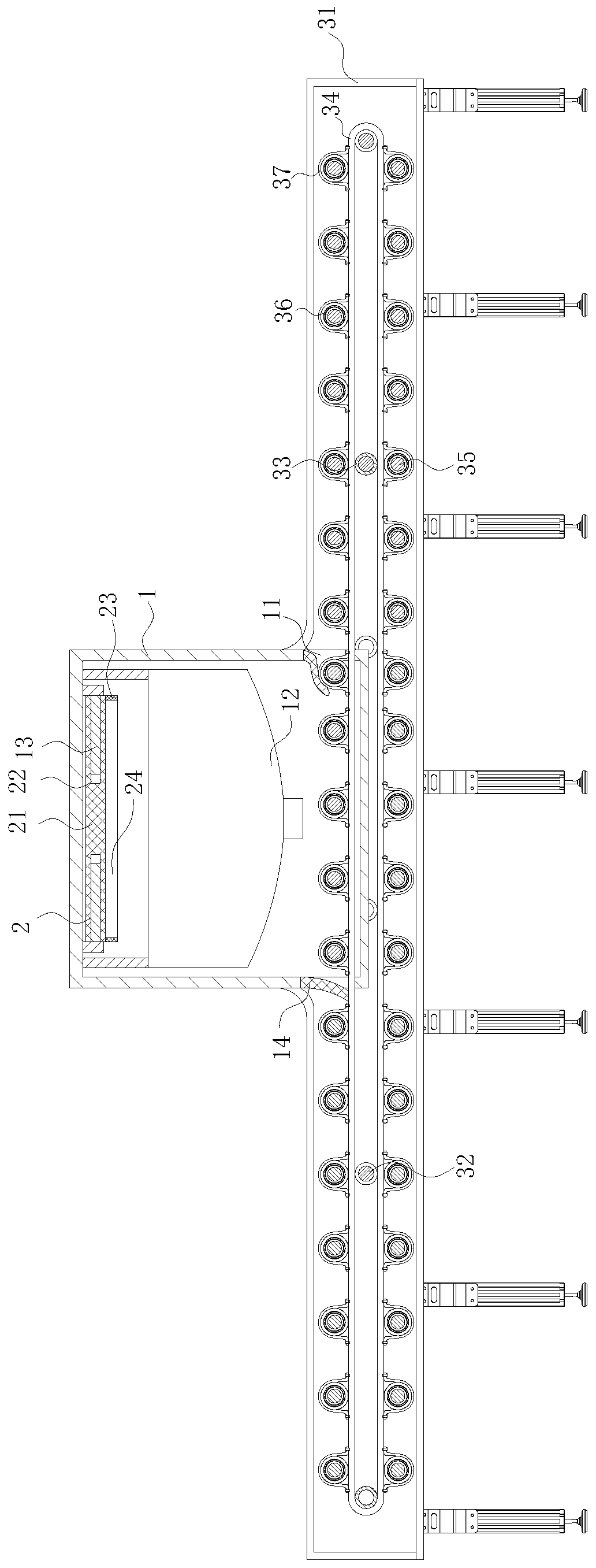

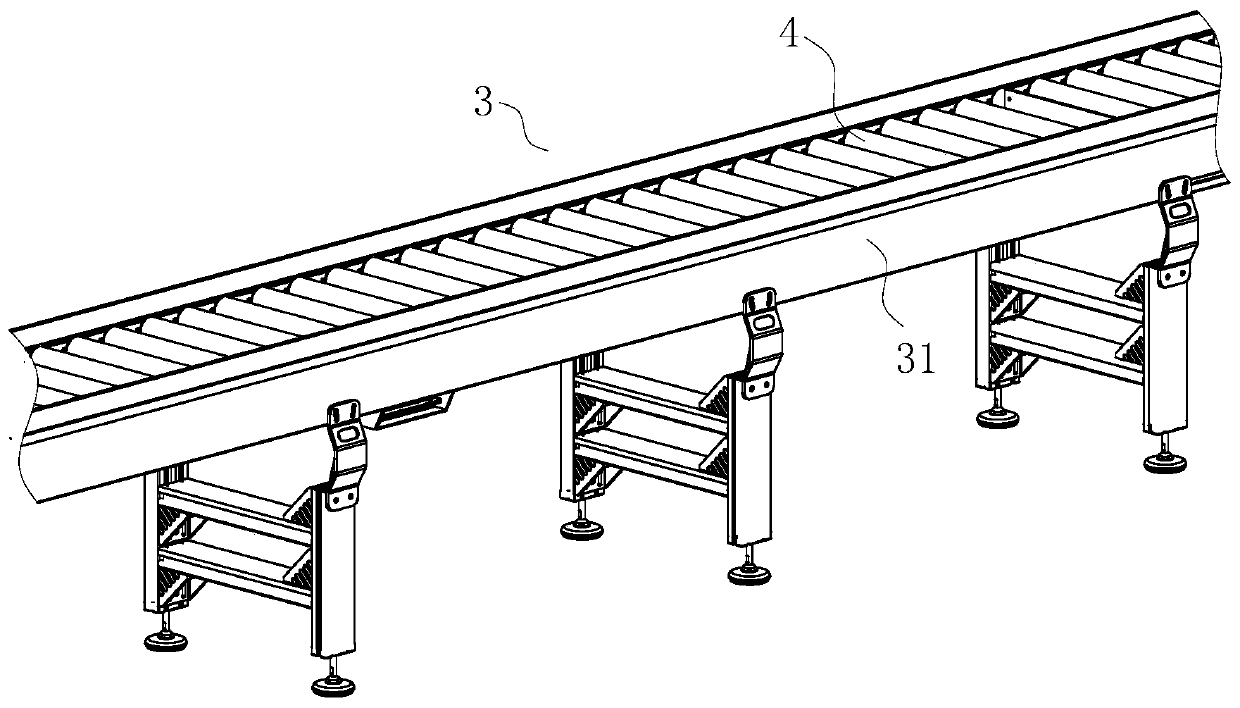

[0029] As a specific embodiment of the present invention, the conversion mechanism 5 includes a driving motor 51, a mounting plate 52, a guiding telescopic rod 53, a rotating guide sleeve 54, a driving gear 56 and a driven gear 57; The plate 52 is installed on the outer wall of the installation frame 31, and the output end of the drive motor 51 is connected with a guide telescopic rod 53; The end passes through the installation frame 31 and is connected with a driving gear 56; the driven gear 57 is installed on the ends of the first rotating shaft 32 and the second rotating shaft 35 respectively; the driving gear 56 is connected to the first rotating shaft 32 and the second rotating shaft The driven gear 57 installed on the two rotating shafts 35 is slidingly engaged, and the driving gear 56 and the driven gear 57 are all set to spur gears; The controller will control the electric telescopic rod to stretch out, and the stretched electric telescopic rod will drive the driving g...

Embodiment approach

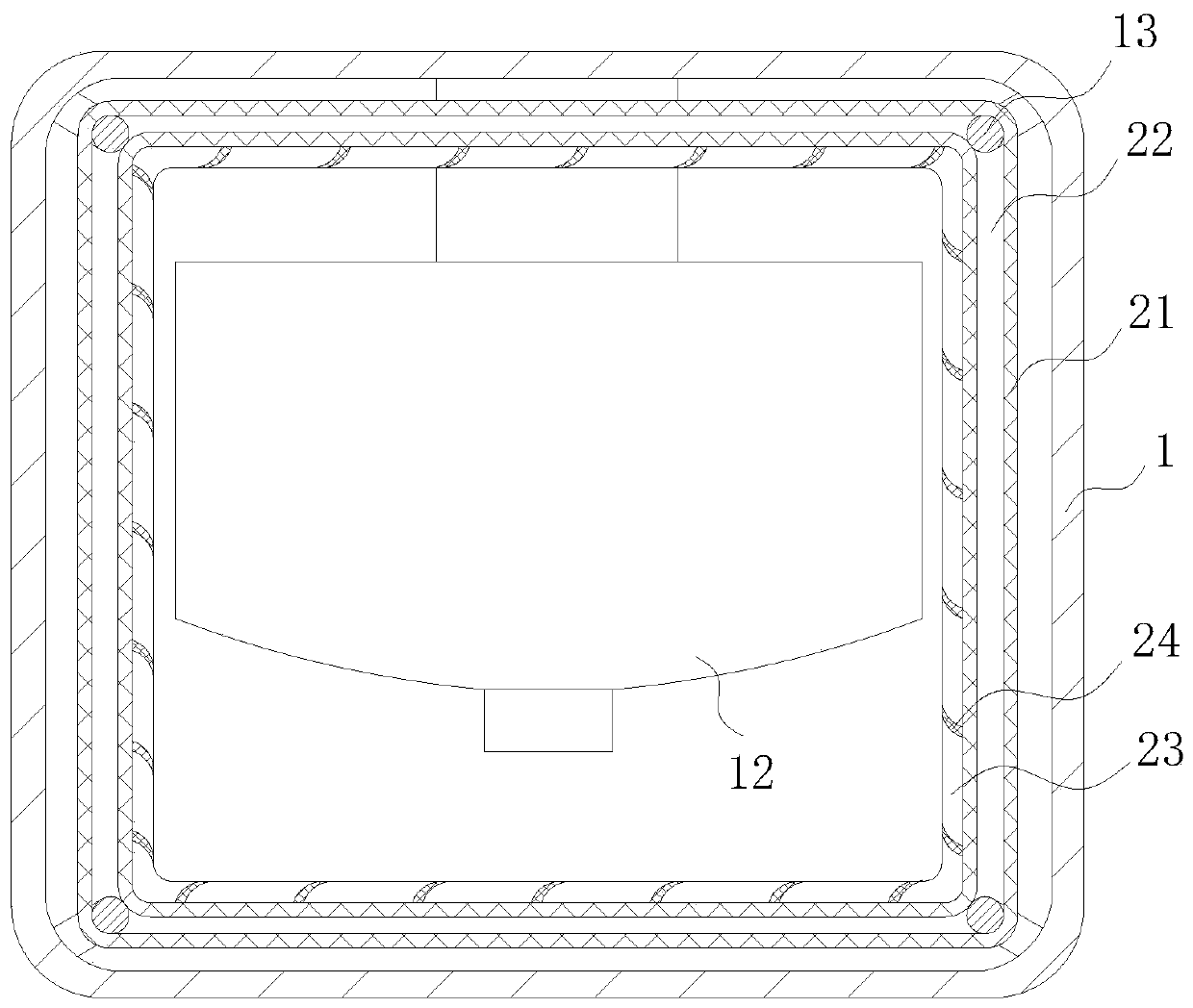

[0032] As a specific embodiment of the present invention, a rubber ring 9 is fixedly installed on the second rotating shaft 35, and a magnet ring 10 is installed on the outer wall of the rubber ring 9, and the circumference of the magnet ring 10 is 9 times that of the rubber ring 9. half; the outer wall of the rotating cylinder 4 is provided with a swing cavity 47, and a metal burr sheet 11 is slidably installed in the swing cavity 47; the bottom end of the metal burr sheet 11 is provided with a magnet block, and the magnet block and the magnet ring are The same magnetic pole; during work, when the second rotating shaft 35 rotates, the second rotating shaft 35 will drive the rubber ring 9 to rotate, and the rubber ring 9 will drive the magnet ring 10 to rotate in the rotating cylinder 4, because the outer wall of the rotating cylinder 4 slides A metal burr sheet 11 is provided, and the repulsive force of the rotation of the magnet ring will cause the metal burr sheet 11 to prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com