Intelligent logistics conveyor for flexible dynamic centralized reorganization and storage of warehouse

An intelligent logistics and conveyor technology, applied in the field of intelligent modern logistics, can solve the problems that the size and size of small logistics robots and the corresponding handling goods cannot be measured one by one, the project progress is prolonged, and system loopholes are exposed. Storage system, improve the protection degree of lifting, avoid the effect of work collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

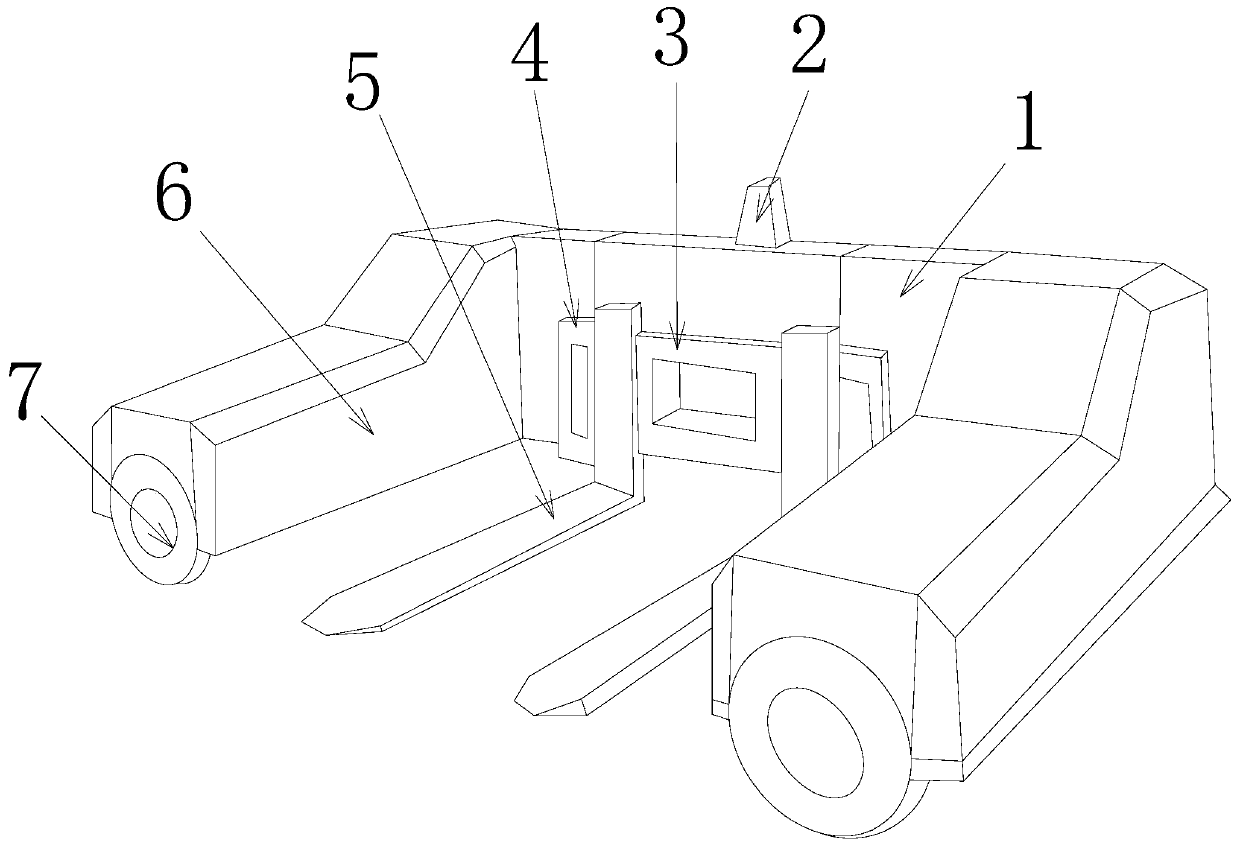

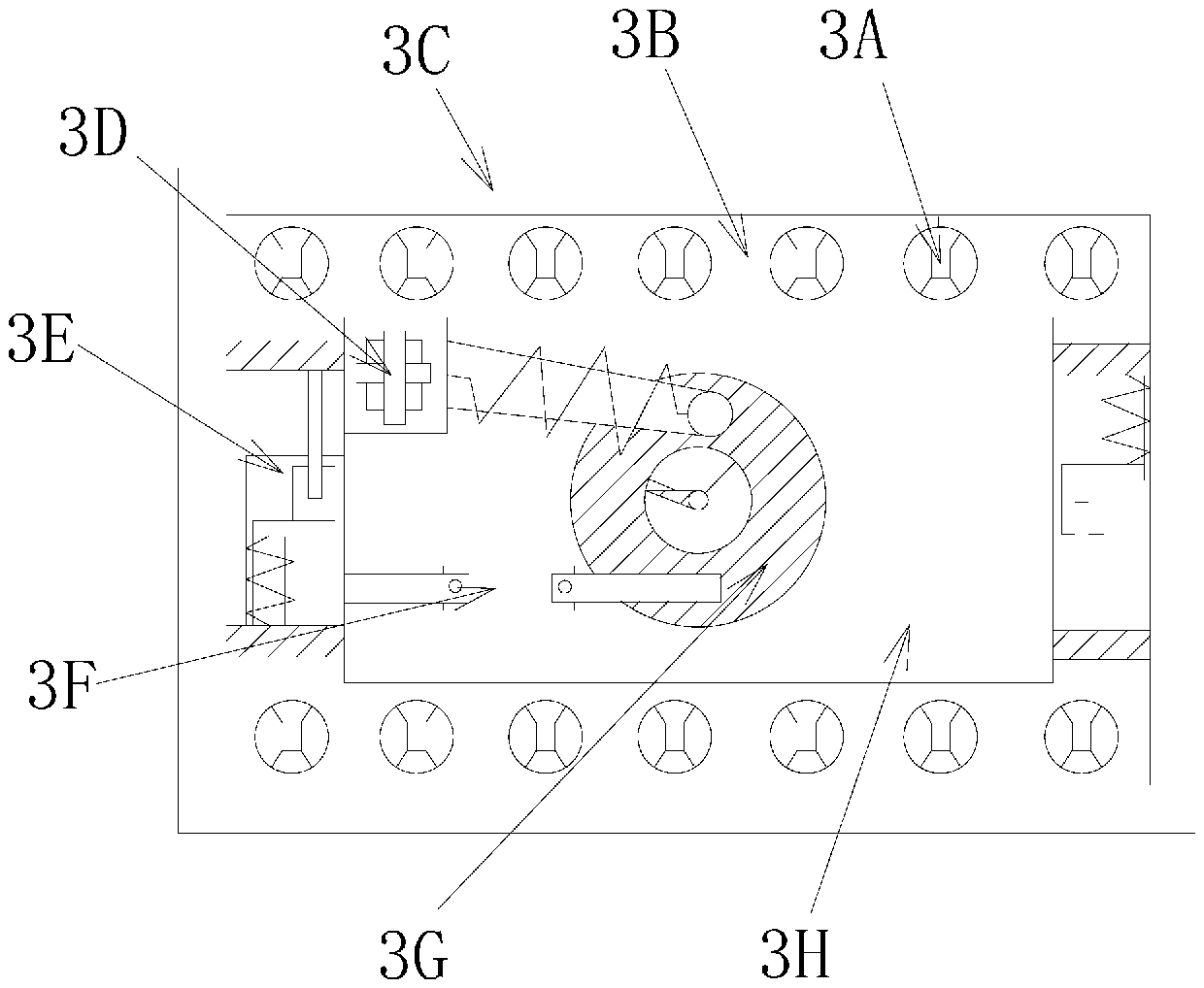

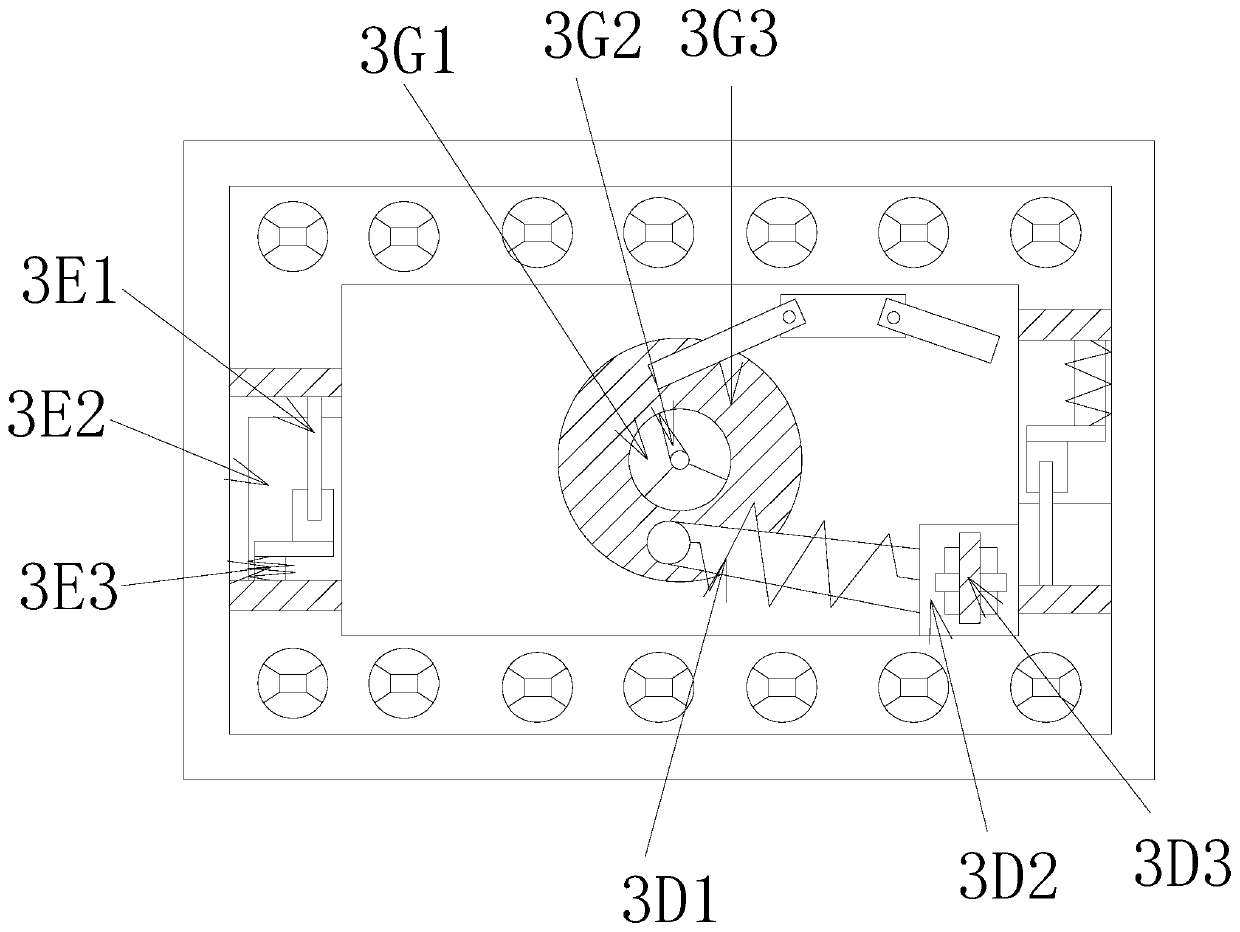

[0032] See Figure 1-Figure 7 , The present invention provides an intelligent logistics conveyor for flexible and dynamic centralized warehousing of warehouses. Its structure includes: vertical plate column block 1, hook ear seat 2, suction cup sliding frame groove 3, auxiliary sticker frame 4, fork support bracket Plate 5, clamping power arm 6, moving wheel 7, the suction cup sliding frame groove 3 is closely attached to the front side of the upright column block 1, and the hook ear seat 2 is welded to the middle section of the upright column block 1. And on the same vertical plane, the auxiliary sticker frame 4 and the fork support plate 5 are both provided with two and are respectively installed on the left and right sides of the suction cup sliding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com