Hardware polishing dust recycling machine

A technology for recycling machines and dust, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., and can solve problems such as dust melting, difficult dust recovery, and impact on dust recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

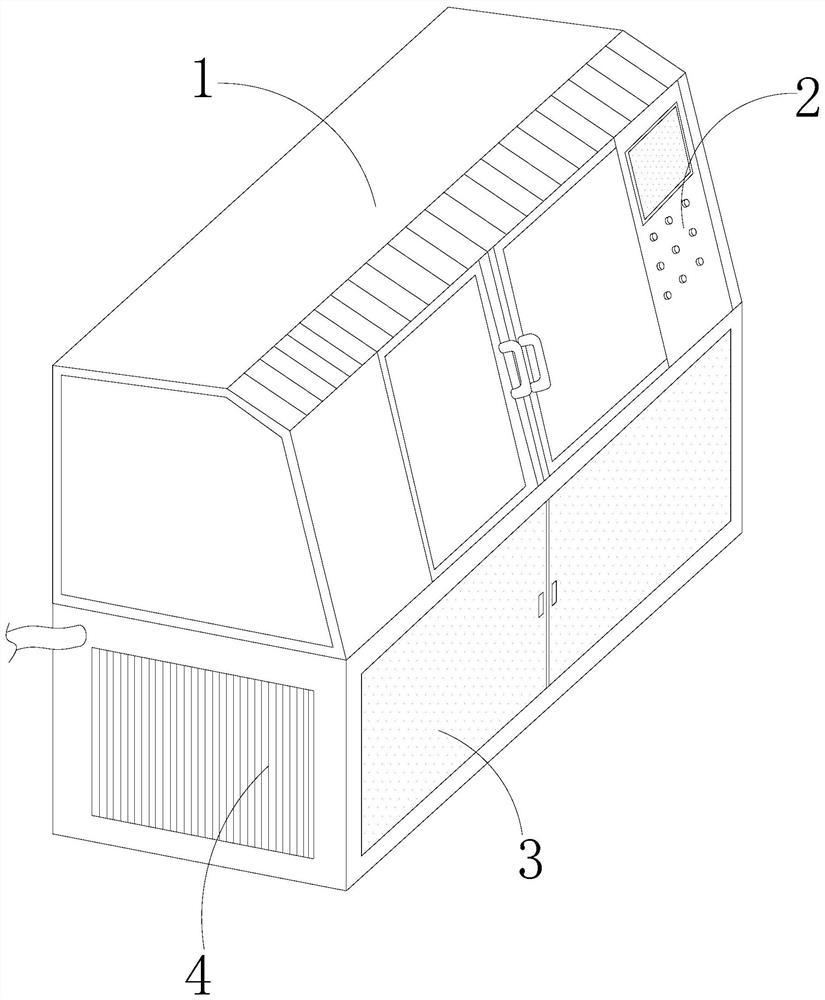

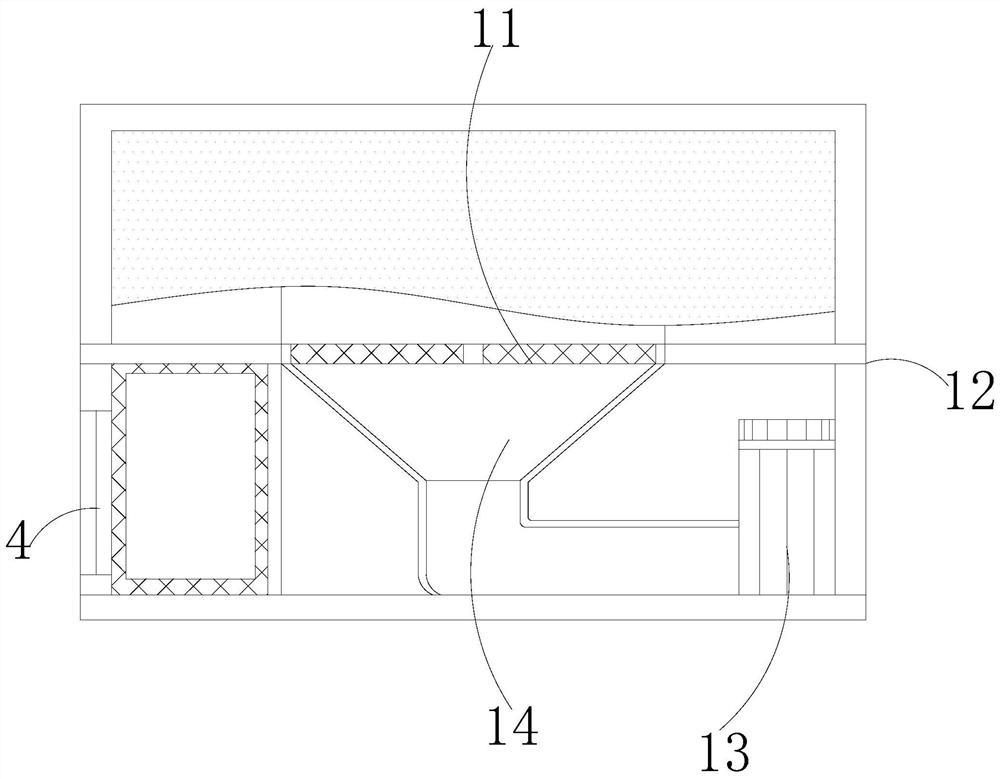

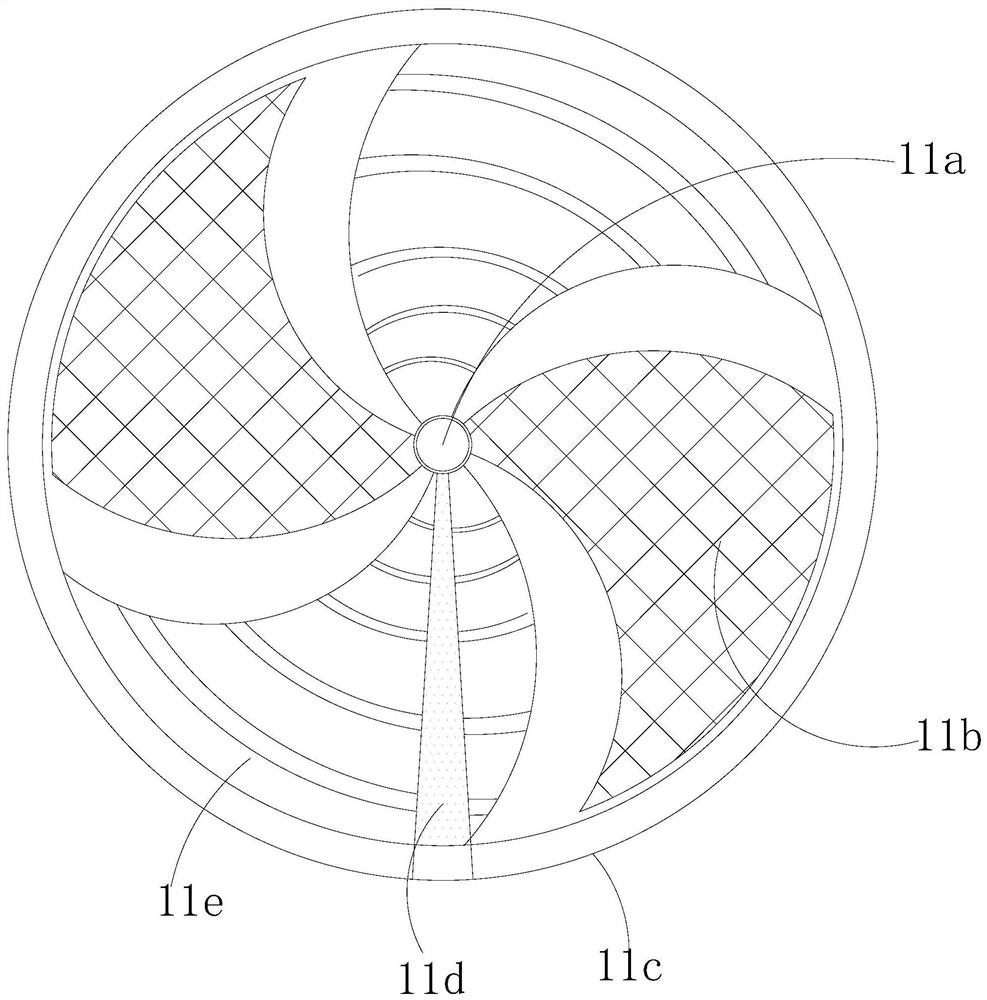

[0025] like Figure 1-Figure 5 Shown:

[0026] The present invention is a hardware polishing dust recovery machine, its structure includes a recovery device 1, a control switch 2, a closed door 3, and an exhaust hole 4, the control switch 2 is embedded on the right side of the recovery device 1, and the closed door 3 Engaged in the right side of the lower end of the recovery device 1, the exhaust hole 4 is installed on the left side of the lower end of the recovery device 1, and the recovery device 1 is provided with a blocking mechanism 11, a fixed box 12, an air extractor 13, and a circulation port 14, The blocking mechanism 11 is installed in the middle of the fixed box 12, the air exhauster 13 is embedded in the lower end of the fixed box 12, the circulation port 14 is located at the lower end of the blocking mechanism 11, and the left side of the fixed box 12 is connected to the exhaust hole. 4-phase embedded, the circulation port 14 is an upward circular opening shape, ...

Embodiment 2

[0033] like Figure 6-Figure 8 Shown:

[0034] Wherein, the fixed mechanism 11d is provided with a fixed rod d1, a parallel rod d2, a movable mechanism d3, a sponge board d4, and a spring rod d5, the parallel rod d2 is connected to the right side of the fixed rod d1, and the spring rod d5 is installed on a parallel The lower end of the rod d2, the movable mechanism d3 is embedded in the lower end of the spring rod d5, the sponge board d4 is attached to the upper surface of the movable mechanism d3, the fixed rod d1 is welded to the upper end of the fixed ring 11c, and the movable mechanism d3 is an arc Shaped structure, cooperates with the clearance on the upper surface of the cleaning structure 11b to clean the dust condensed on the upper surface of the cleaning structure 11b.

[0035]Wherein, the movable mechanism d3 is provided with a connecting rod d31, a fitting structure d32, an inclined block d33, and a limit shaft d34, the limit shaft d34 is installed on the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com