Apparatus for conveying exhaust fumes from marine ship engines into scrubbers

A technology for scrubbers and ships, used in exhaust devices, mufflers, exhaust treatment, etc., and can solve problems such as less heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

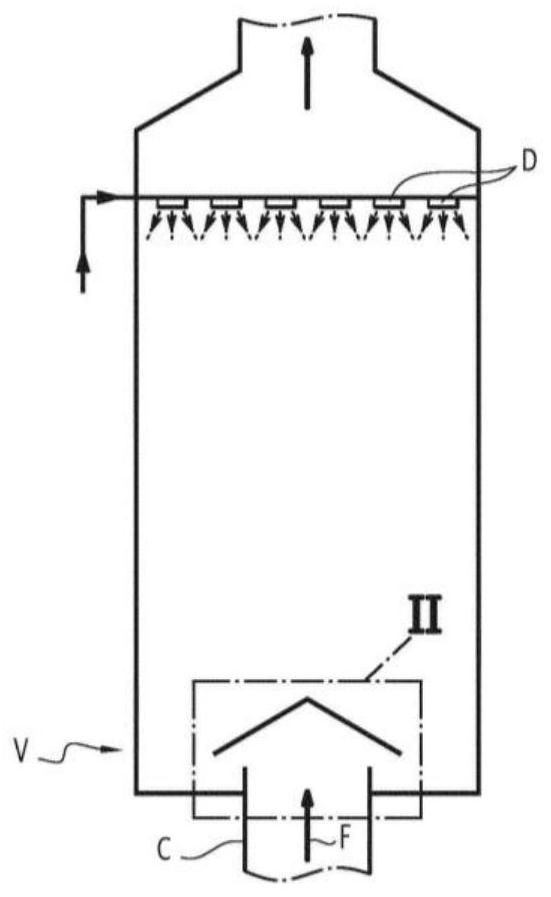

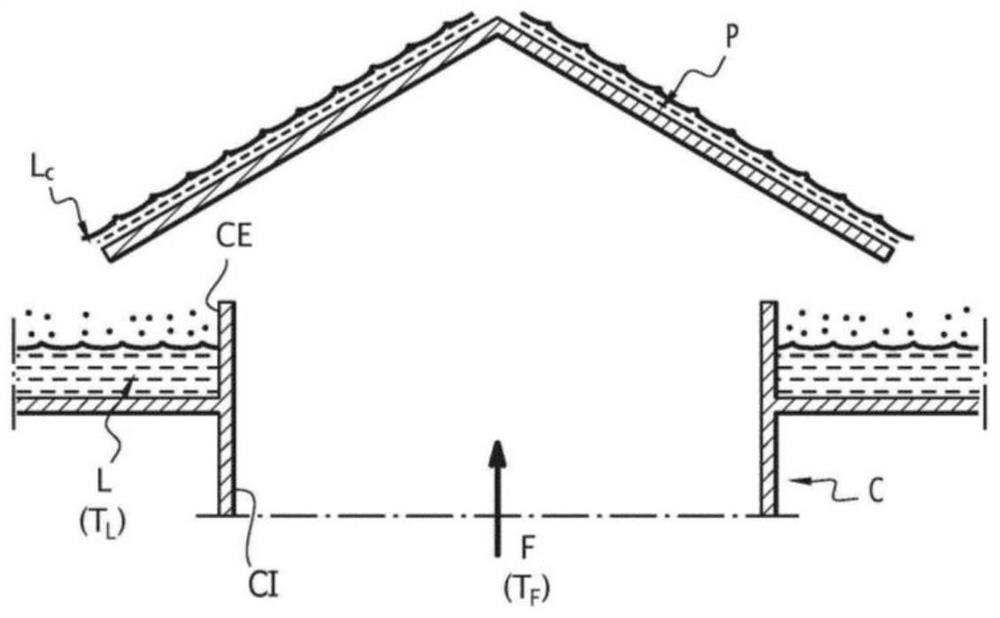

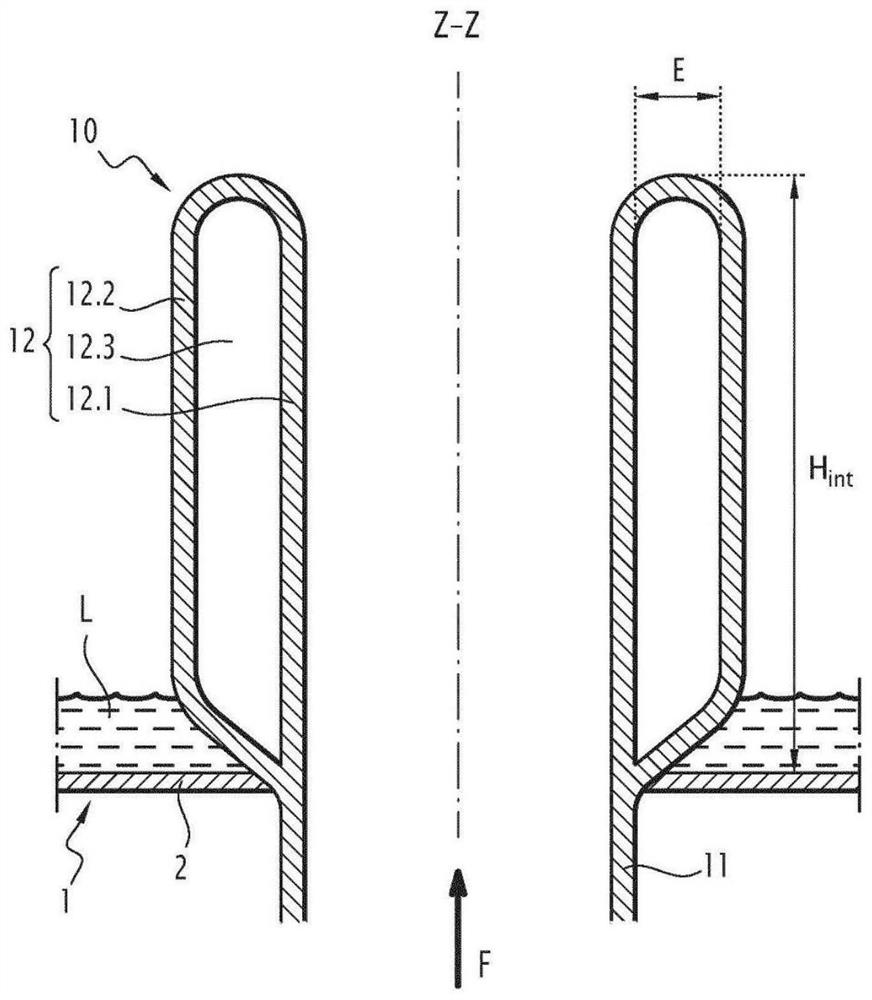

[0039] image 3 Shown is a device for transporting fumes belonging to a treatment facility, which makes it possible to clean the exhaust fumes F of the diesel engines of the diesel engines propelling the marine vessel on board the treatment facility. Smoke F contains especially sulfur oxides, especially sulfur dioxide (SO 2 ). image 3 The device makes it possible to transport the fumes F to the desulfurization scrubber 1, where image 3 Only the bottom wall 2 of the desulfurization scrubber 1 can be seen in the figure.

[0040] The scrubber 1 , the embodiment of which does not limit the invention, is functionally or even structurally similar to the scrubber V previously described with reference to FIG. 1 . The scrubber 1 thus overall assumes the shape of a tower which, during use, extends longitudinally vertically. At its base, the scrubber 1 has a bottom wall 2 from which the peripheral wall of the scrubber extends, ending in an apex: during use, the exhaust fumes F are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com